Wind power tower barrel door frame welding platform

A technology for welding platforms and wind power towers, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long time consumption, inconvenient operation, space occupation, etc., and reduce the number of installation and disassembly, welding operations Convenience and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

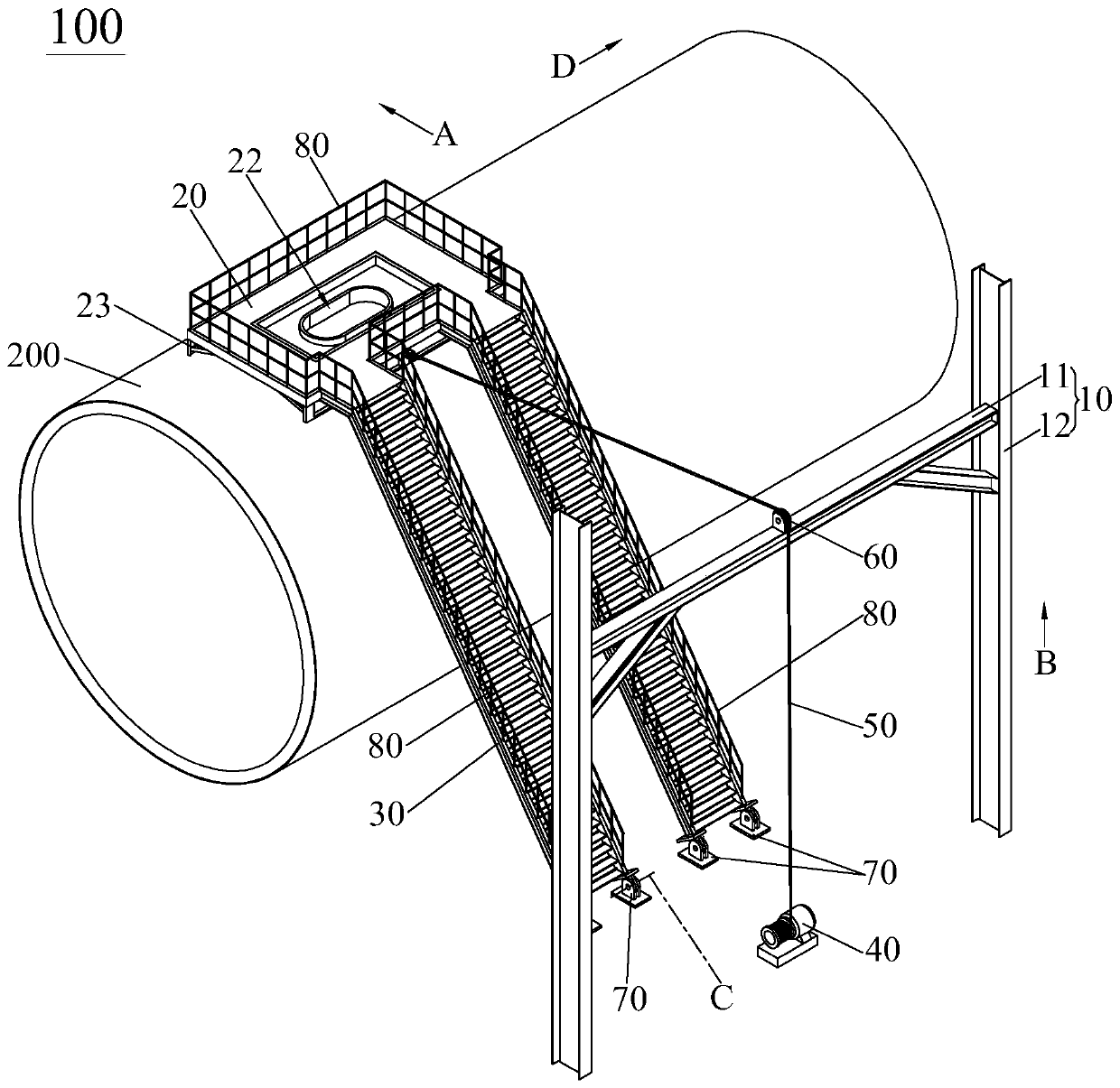

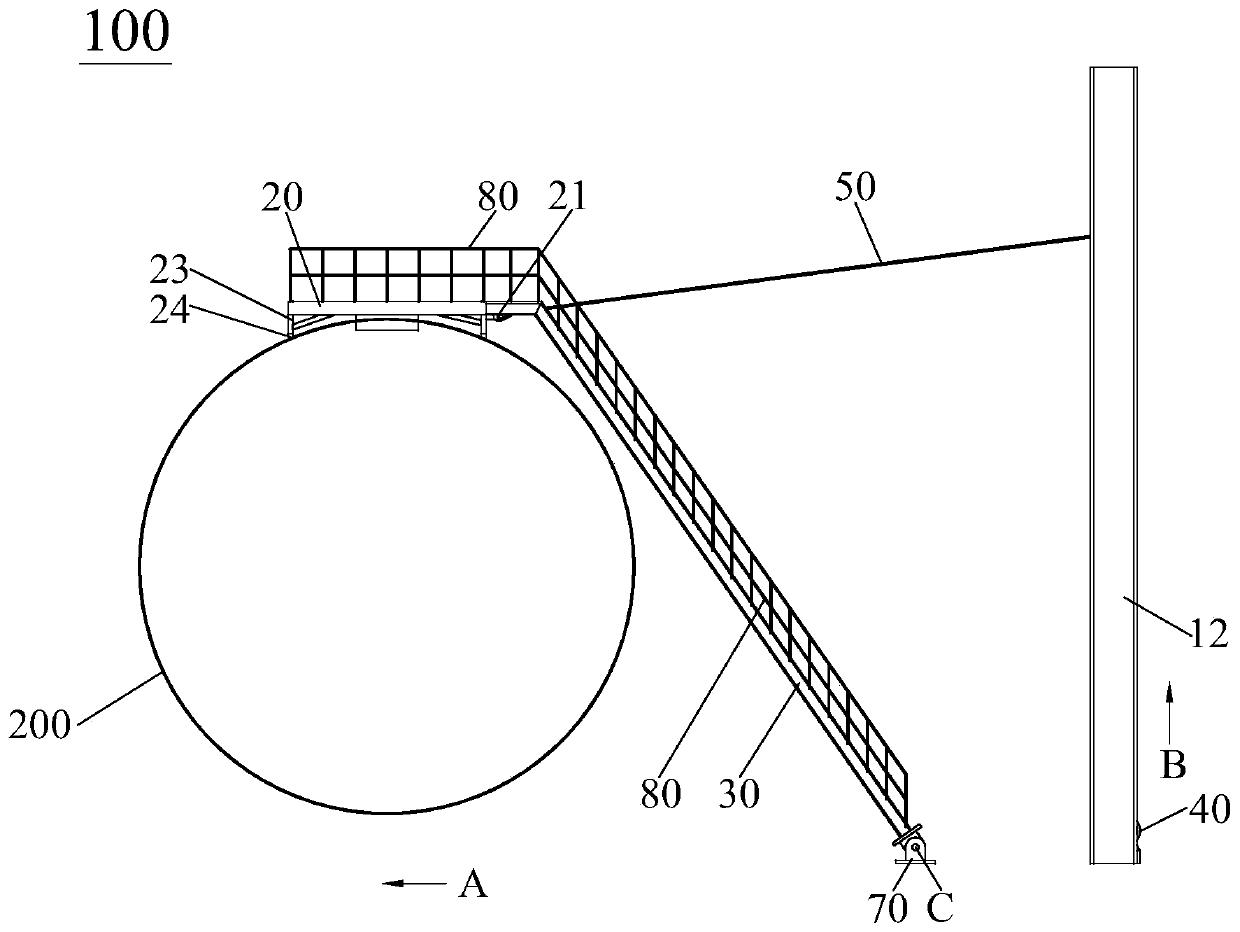

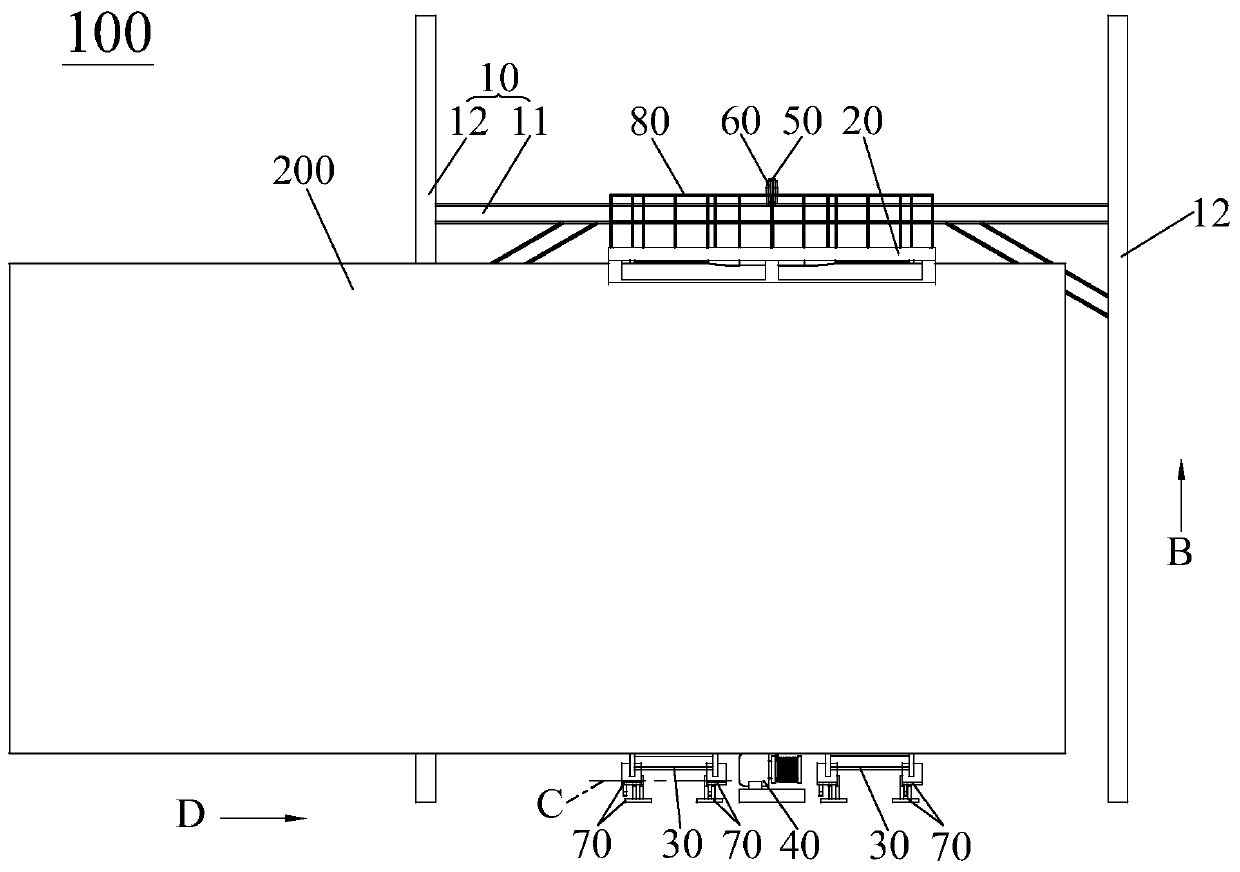

[0021] see Figure 1 to Figure 3 , the wind power tower door frame welding platform 100 of the present invention is applied to the door frame welding of the wind power tower 200 placed horizontally, so as to facilitate the operator's welding operation on the door frame of the wind power tower 200 . Wherein, the wind power tower door frame welding platform 100 of the present invention includes a gantry 10 , a walking platform 20 , a ladder 30 , a hoist 40 , a traction member 50 , a fixed pulley 60 and a hinge seat 70 . The fixed pulley 60 is installed on the crossbeam 11 of the gantry 10 to change the direction of the traction force; preferably, the fixed pulley 60 is located in the middle of the crossbeam 11, and the column 12 of the gantry 10 is fixed on the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com