Cobalt-nickel-nitrogen sulfide-doped carbon nanofiber composite and preparation method and application thereof

A technology of cobalt nickel sulfide nitrogen and carbon nanofibers, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of easy agglomeration of pure cobalt nickel sulfide, ineffective transmission of electrons, and limited electrocatalysis Effect and other issues, to achieve the effect of good conductivity, rigorous and mature preparation process, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

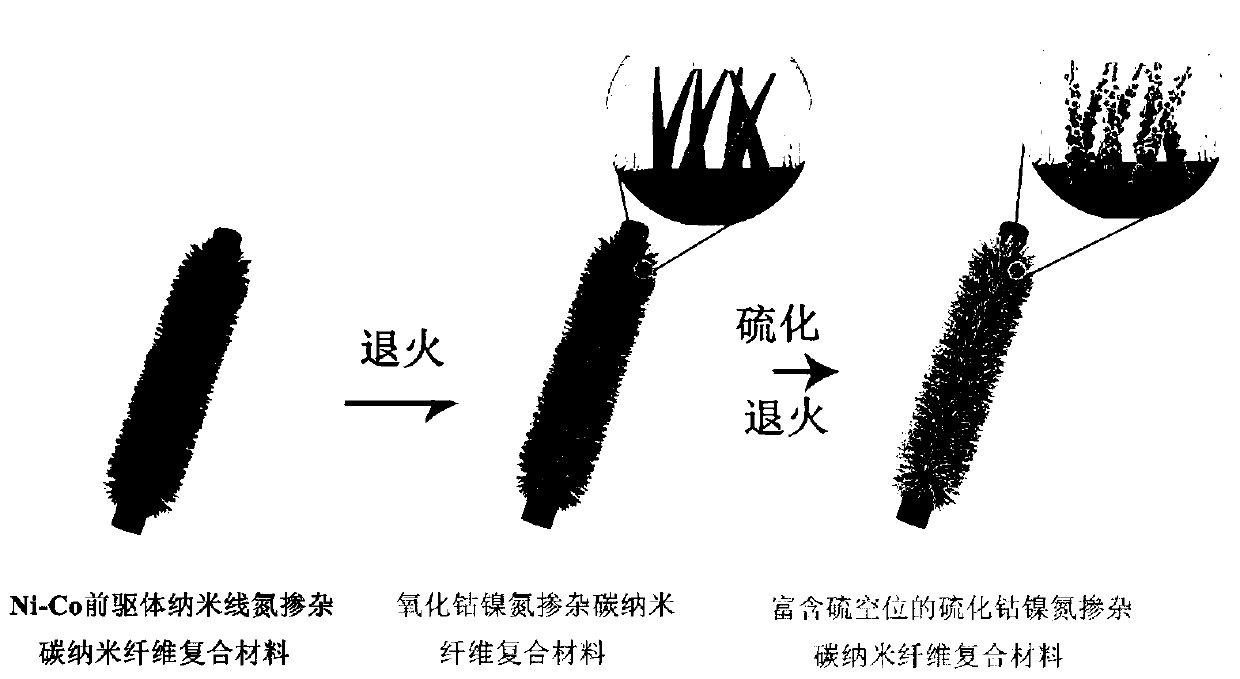

[0037] The embodiment of this city provides a cobalt-nickel-nitrogen-doped carbon nanocomposite material rich in sulfur vacancies, and its specific preparation steps are as follows:

[0038] Step 1: Preparation of nitrogen-doped carbon nanofiber membrane:

[0039] Add 0.9g of polyacrylonitrile and 0.1g of urea into 9g of N,N-dimethylformamide solvent, stir at 25°C for 12h to obtain spinning stock solution, and spin for 6h (specific spinning parameters: use a fiberglass with an inner diameter of 0.8mm The metal needle is used as the nozzle, the spinning voltage is 20KV, the vertical distance from the needle to the receiving screen is 20cm, the spinning temperature is 25° C., the relative humidity of the air is 20RH%, and the aluminum foil of the circular drum receives the spinning nanofibers) to obtain polyacrylonitrile nanofibers. Fiber membrane; put the polyacrylonitrile nanofiber membrane into the oven, raise the temperature to 250°C at a rate of 1°C / min in the air atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com