Automatic shaping device

A shaping and shaping unit technology, applied in physical therapy, massage aids, non-surgical orthopaedic surgery, etc., can solve the problems of high use cost, high cost of shaping clothing, easy corneal inflammation, etc. Realize the effect of automatic control and correction of myopia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

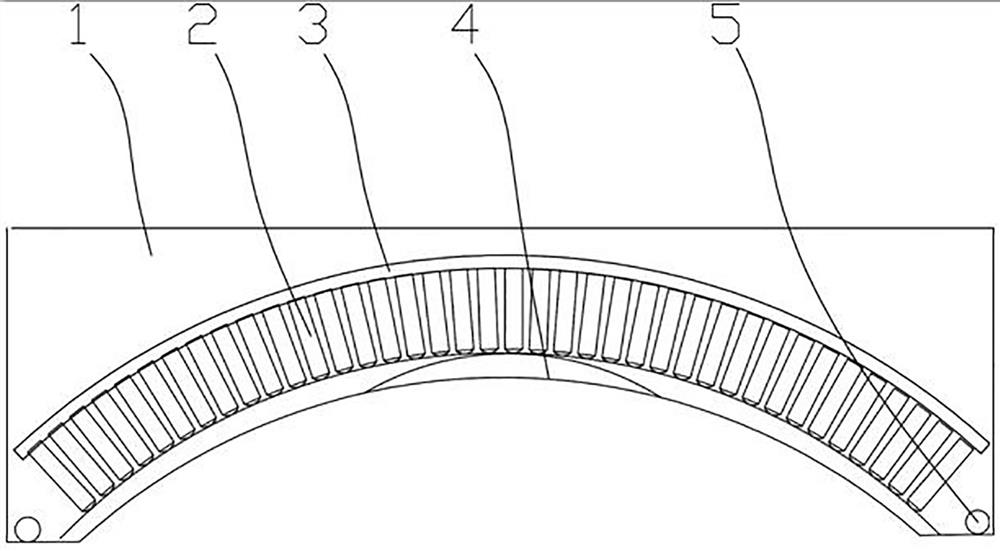

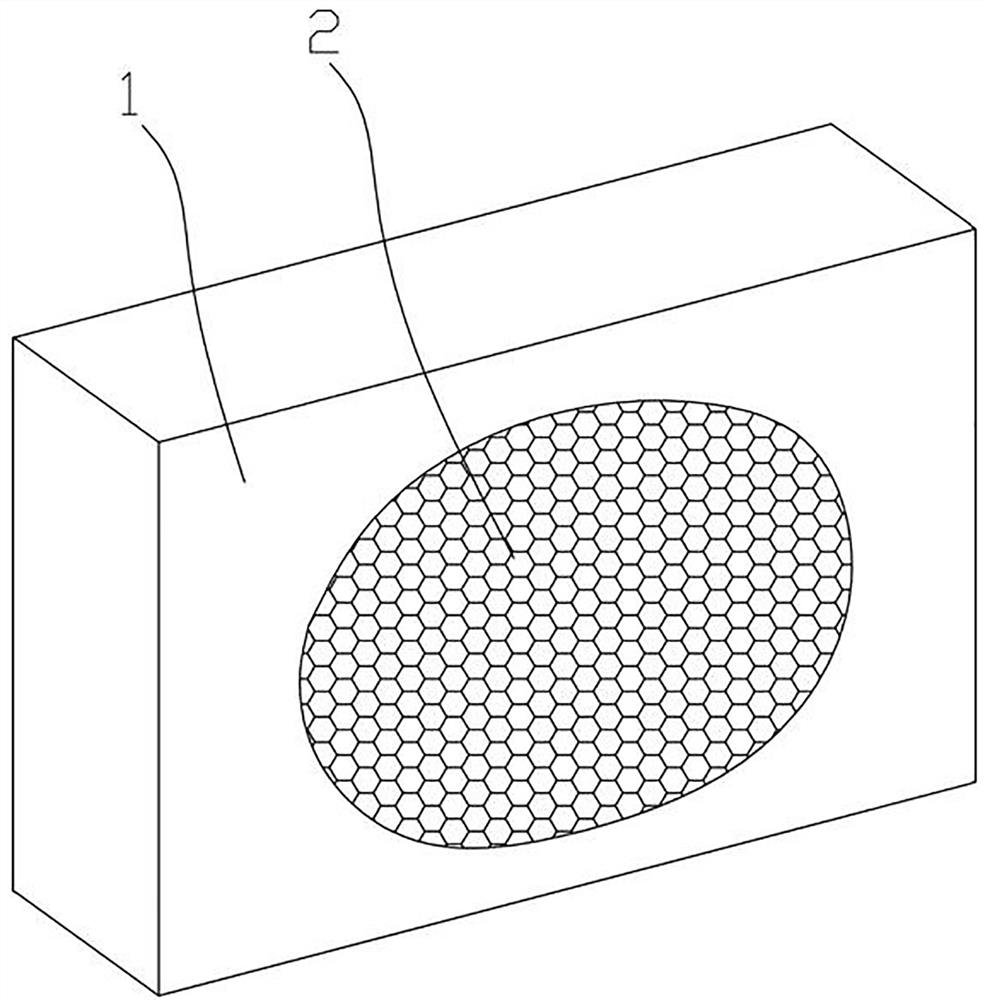

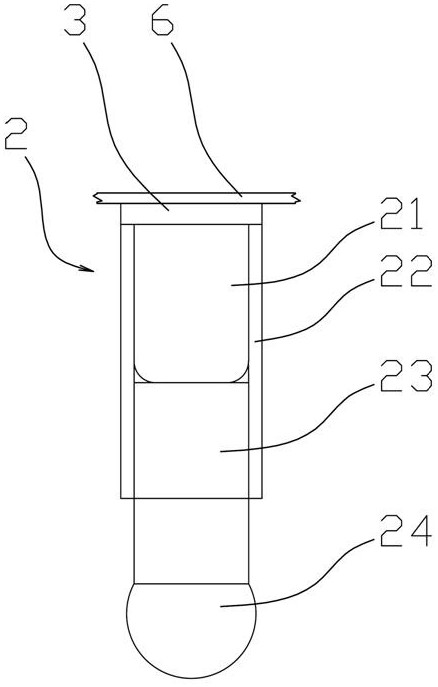

[0027] Such as Figure 1~4 Among them, an automatic shaping device, which includes a base part 1 and a shaping array 2, the shaping array 2 is composed of a plurality of shaping units, and the shaping unit is provided with a retractable pressure head 23, and the shaping array 2 is fixed by the base part 1, and the indenter 73 of the shaping array 2 forms a shape matching the expected shape of the part to be shaped. The molding described here refers to a structure similar to a mould, that is, the expected shape of the part to be molded is spherical, and the shape formed by the indenter 73 is a spherical groove. With this structure, the shaping array 2 can be formed into any desired shape according to the preset parameters, and can be further changed within a certain range to realize gradual shaping until the expected shape of the shaping area is realized. Thereby saving the high cost caused by a large number of customization and individualized production.

[0028] The preferr...

Embodiment 2

[0032] On the basis of Embodiment 1, in a preferred solution, the temperature control component 3 is an electromagnetic coil, and the electromagnetic coil is electrically connected to an alternating current device; the alternating current device preferably adopts an alternating current generated by an inverter. The inverter is a commercially available product.

[0033] A metal sheet for heating is provided between the temperature control component 3 and the deformation capsule 21 ; or multiple metal sheets are provided in the deformation capsule 21 . The alternating magnetic field generated by the alternating current in the electromagnetic coil heats the metal sheet, thereby heating the temperature-sensitive medium, so as to control the volume change of the deformable capsule 21 .

[0034] In a preferred solution, the electromagnetic coil array is arranged, and the electromagnetic coil is electrically connected to the alternating current device through the scanning circuit, an...

Embodiment 3

[0036]On the basis of Example 1, another preferred scheme is as Figure 3~6 In the above, the temperature control component 3 is a semiconductor heating chip, and the semiconductor heating chip is connected to the deformation capsule 21 in a heat conduction manner.

[0037] The preferred solution is as Figure 6 Among them, the semiconductor heating chip is electrically connected to the DC power supply through the scanning circuit, a switch array 8 is arranged on the vertical and horizontal lines of the scanning circuit, the switching array 8 is electrically connected to the main control chip 7, and one end of the semiconductor heating chip is connected to the node of the scanning circuit , and the other end is grounded. With this structure, it is possible to independently control the opening and closing of each semiconductor heating sheet, such as Figure 5 Among them, the heating temperature of the electromagnetic coil is controlled by the pulse signal given by the main co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com