Environment-friendly water-permeable grass prevention cloth and production equipment

A technology for production equipment and weed-proof cloth, which is applied in the field of environmentally friendly water-permeable weed-proof cloth and production equipment, can solve the problems of plant root rot, poor air permeability, and insufficient water absorption capacity of plant roots, etc., and achieve the goal of ensuring the bonding effect and speed synchronization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

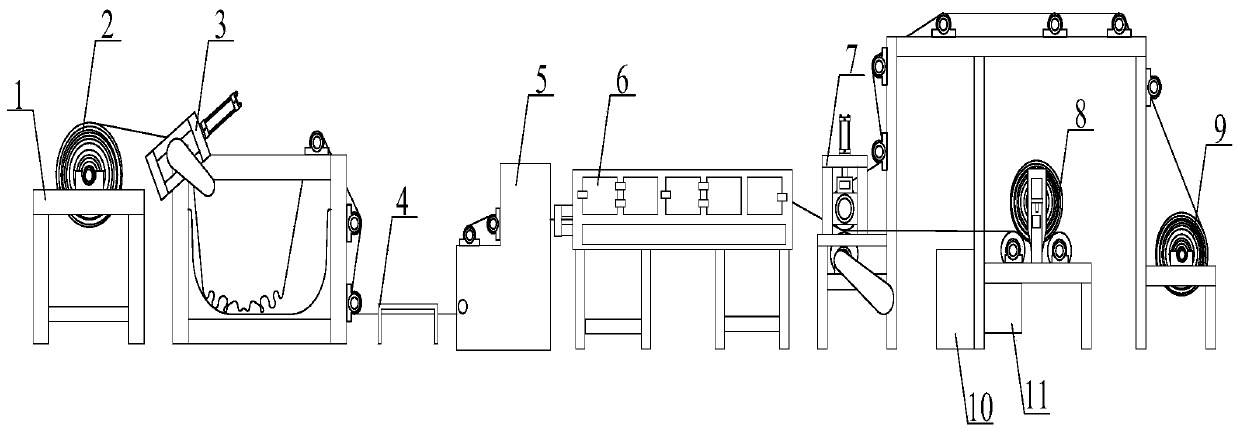

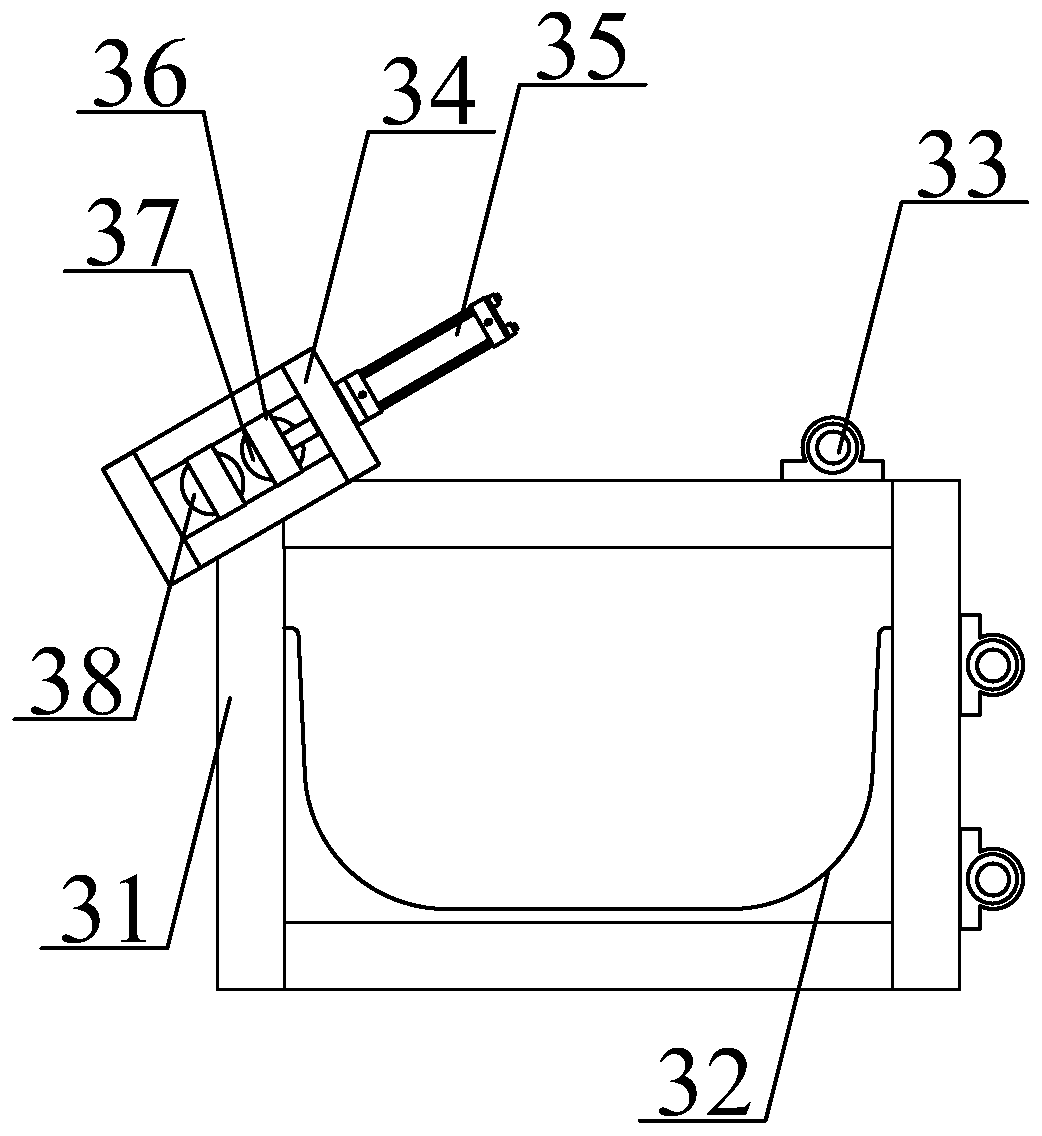

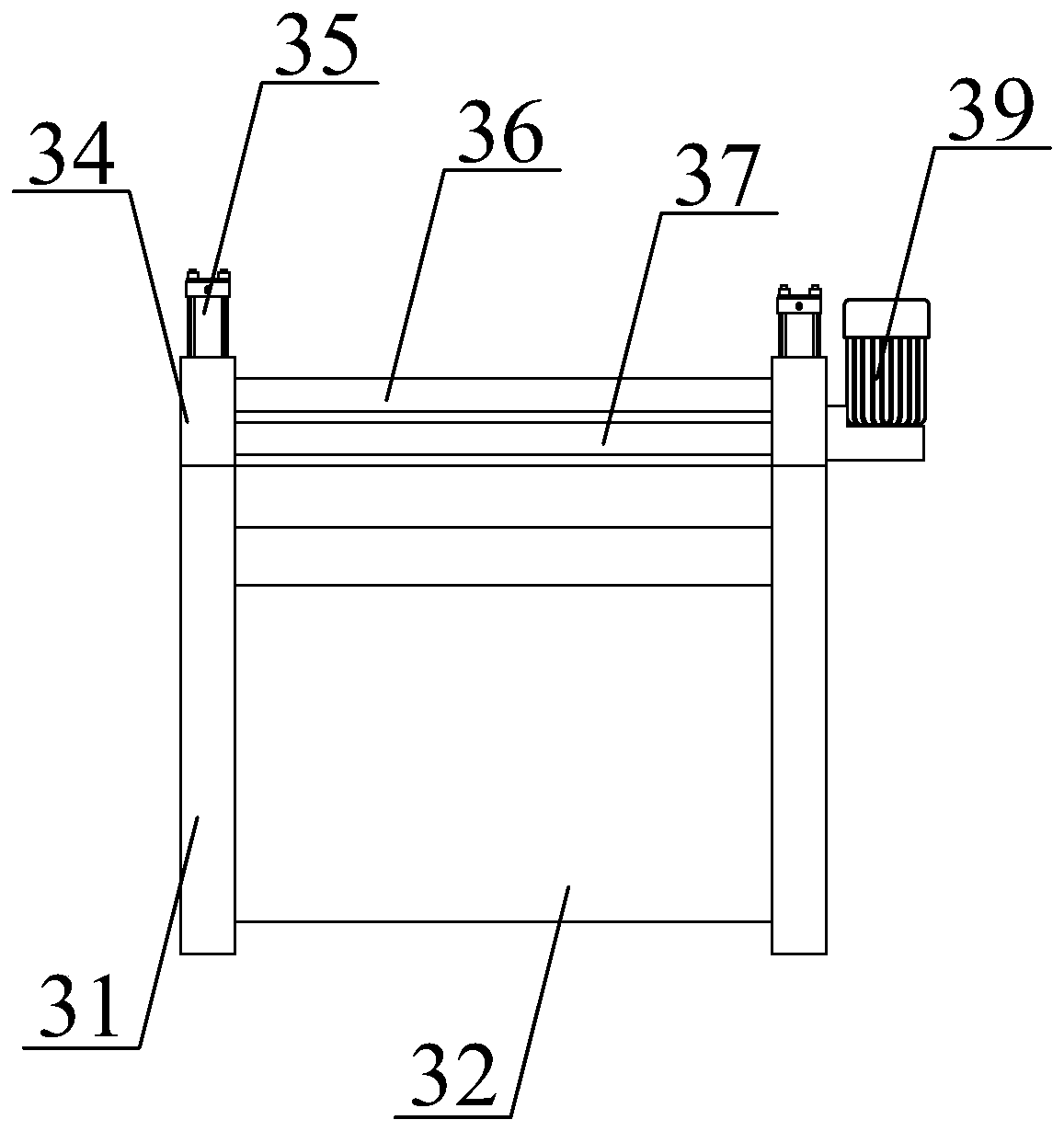

[0032] like Figure 1-9 As shown, the present invention provides a technical solution: an environment-friendly water seepage type grass-proof cloth and production equipment, including an unwinding frame body, a PET staple fiber knitted and punctured non-woven fabric roll, a cloth storage device, an aisle board, an EVA sprinkling Powder machine, heating and baking melting machine, compound winding device, grass-proof cloth roll, PP spunbonded non-woven fabric, electrical control cabinet and pneumatic control cabinet, the PET staple fiber knitted and punched non-woven fabric roll is set on the unwinding rack On the body, and one end of the PET staple fiber knitted punctured non-woven fabric roll enters the cloth storage device; the passage board is set between the cloth storage device and the EVA powder spreader; the heating, baking and melting machine is set At the right end of the EVA powder spreader; the composite winding device is located on the right side of the heating, ba...

Embodiment 2

[0034] An environment-friendly and water-permeable grass-proof cloth and its production equipment, including an unwinding frame body, a roll of PET short-fiber knitted and punched non-woven fabric, a cloth releasing and storing device, an aisle board, an EVA dusting machine, a heating baking melting machine, and a composite winding device, grass-proof cloth roll, PP spunbonded non-woven fabric, electrical control cabinet and pneumatic control cabinet, the PET staple fiber knitted and punched non-woven fabric roll is set on the unwinding frame body, and PET staple fiber knitted and punched non-woven fabric One end of the cloth roll enters the cloth releasing and storing device; the passage plate is arranged between the cloth releasing and storing device and the EVA powder spreading machine; the heating, roasting and melting machine is arranged at the right end of the EVA powder spreading machine; The composite winding device is located on the right side of the heating, baking an...

Embodiment 3

[0037] An environment-friendly and water-permeable grass-proof cloth and its production equipment, including an unwinding frame body, a roll of PET short-fiber knitted and punched non-woven fabric, a cloth releasing and storing device, an aisle board, an EVA dusting machine, a heating baking melting machine, and a composite winding device, grass-proof cloth roll, PP spunbonded non-woven fabric, electrical control cabinet and pneumatic control cabinet, the PET staple fiber knitted and punched non-woven fabric roll is set on the unwinding frame body, and PET staple fiber knitted and punched non-woven fabric One end of the cloth roll enters the cloth releasing and storing device; the passage plate is arranged between the cloth releasing and storing device and the EVA powder spreading machine; the heating, roasting and melting machine is arranged at the right end of the EVA powder spreading machine; The composite winding device is located on the right side of the heating, baking an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com