Novel micro nano fiber Bragg grating refractive index sensor

A technology of refractive index sensor and Bragg grating, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve problems such as multiple effective signal bandwidths, signal annihilation, and expansion of the initial wavelength difference of reflected signals. Achieve the effect of avoiding occupation and crosstalk between signals, avoiding "water absorption" area, and high degree of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

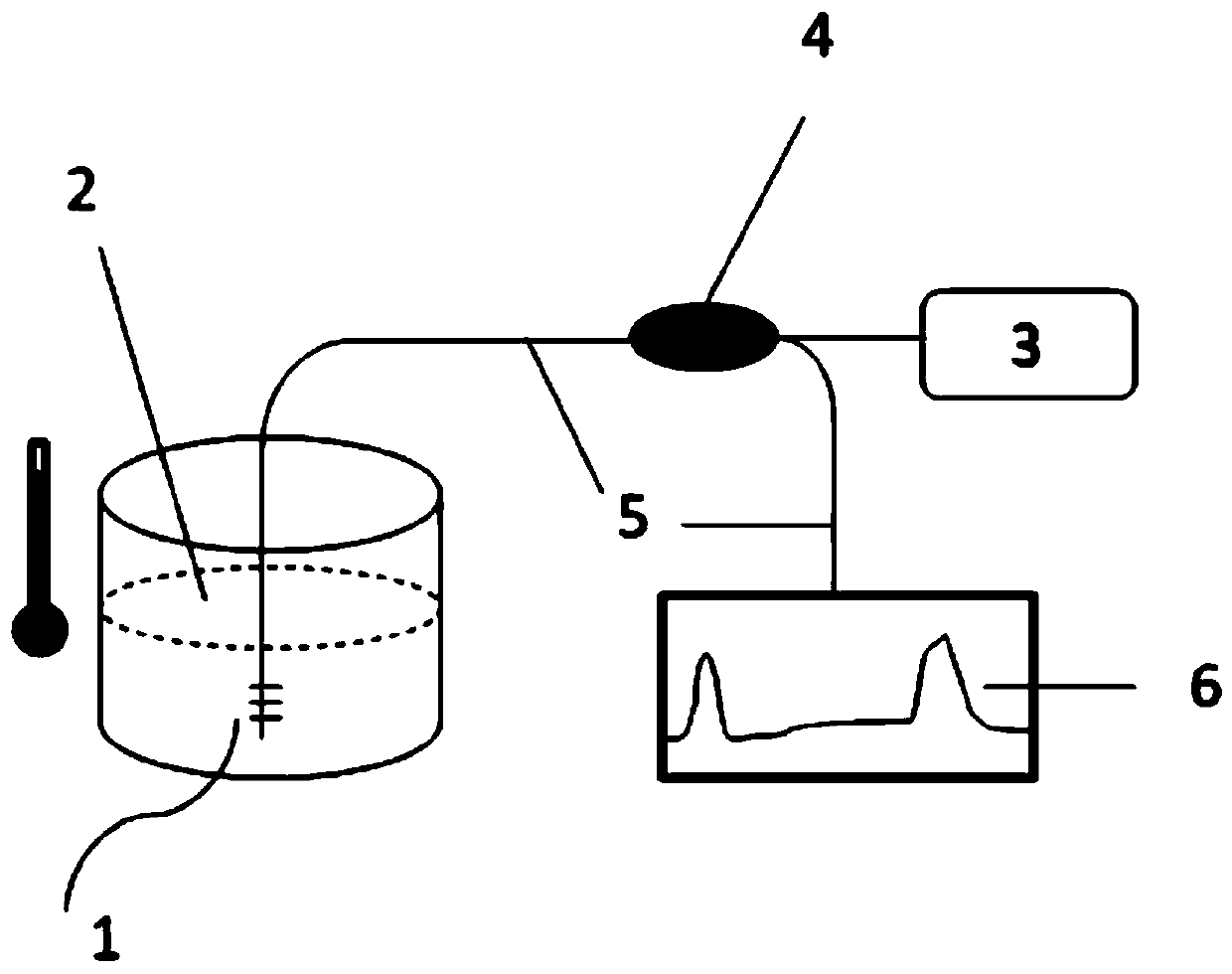

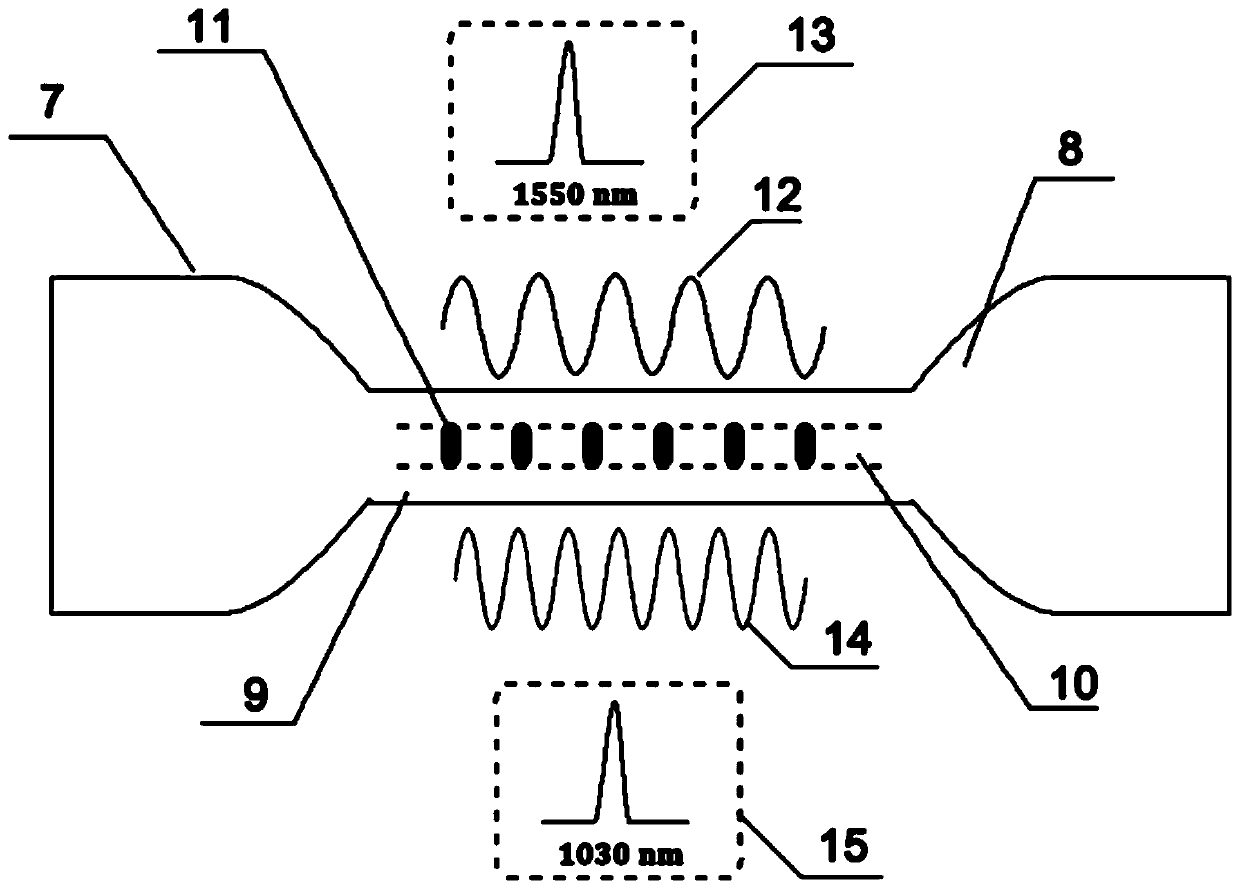

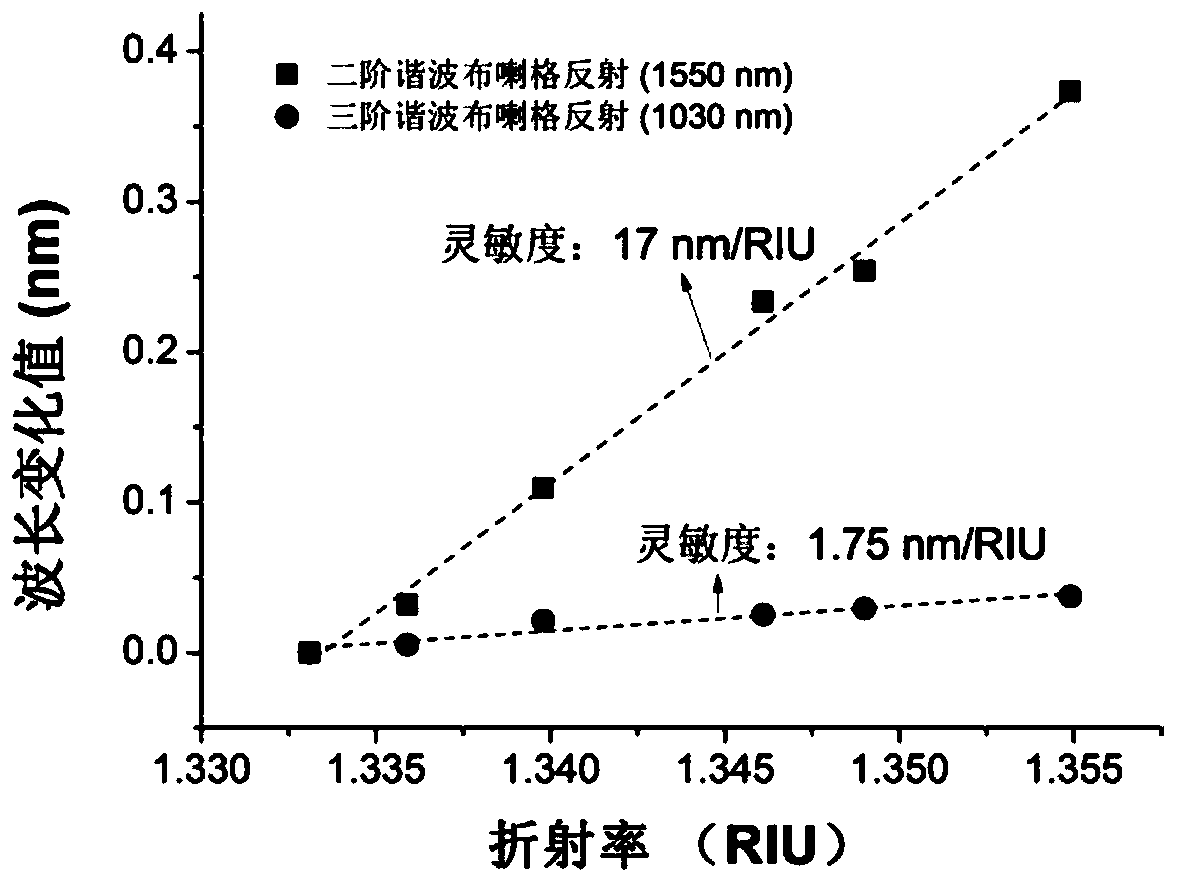

[0037] A new type of micro-nano fiber Bragg grating refractive index sensor, such as figure 1 As shown, it includes a broadband light source 3, an optical coupling element 4, a micro-nano fiber Bragg grating 1 connected in sequence, and a wavelength detection unit 6 connected to the optical coupling element 4; between the broadband light source 3 and the optical coupling element 4, the optical fiber The coupler 4 is connected with the micro-nano fiber Bragg grating 1 , the optical coupling element 4 and the wavelength detection unit 6 through a single-mode communication optical fiber 5 .

[0038] After the broadband optical signal emitted by the broadband light source 3 passes through the optical coupling element 4, it is incident on the micro-nano fiber Bragg grating 1 in the solution 2 to be tested, and the micro-nano fiber Bragg grating 1 is inserted into the solution 2 to be tested as a sensing probe Among them, the spectral lines of the micro-nano fiber Bragg grating 1 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com