Semiconductor laser array packaging structure

A technology of laser array and packaging structure, applied in the field of optical communication, to achieve the effect of simple arrangement, large-scale production and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

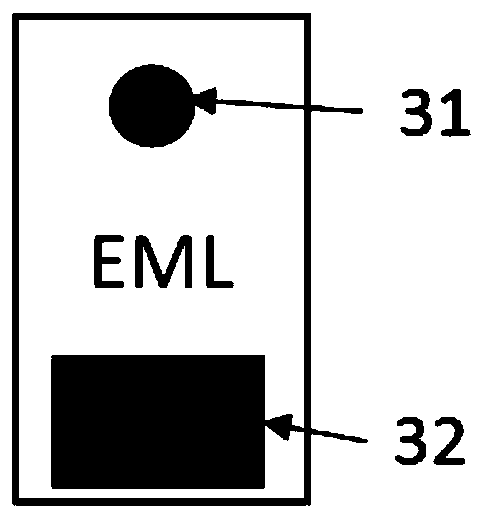

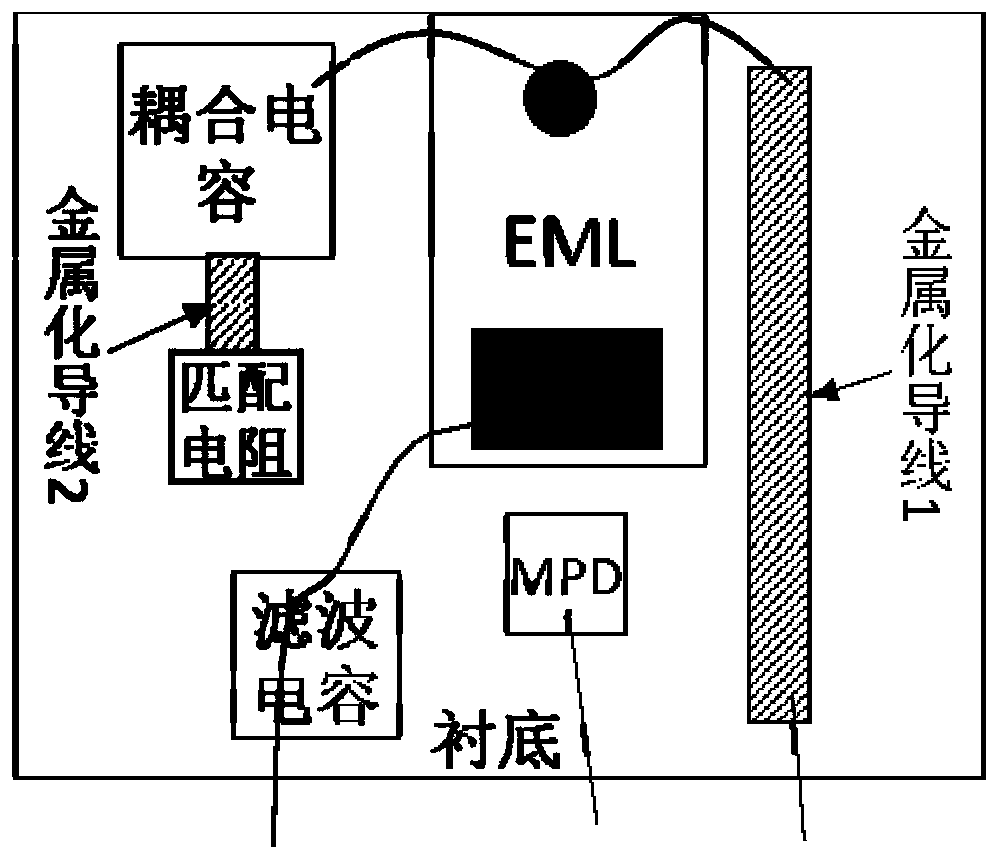

[0043] In addition to the EML array, the materials required for packaging also need a substrate, four filter capacitors, four coupling capacitors, four MPDs and four matching resistors. image 3It is the front structure of the EML array package in this embodiment. The plane where the substrate is located is defined as the xy plane. EML1, EML2, EML3, and EML4 are arranged in sequence along the x direction of the substrate and mounted on the front of the substrate with the back facing up to form an EML unit. ; The filter capacitor 1, the filter capacitor 2, the filter capacitor 3 and the filter capacitor 4 are arranged along the x direction of the substrate and mounted on the front side of the substrate to form a filter capacitor unit; MPD1, MPD2, MPD3 and MPD4 are also sequentially arranged along the substrate The x-direction of the bottom is arranged and mounted on the front of the substrate to form an MPD unit; EML, MPD and filter capacitors correspond one by one, and the EML ...

Embodiment 2

[0048] The difference from Embodiment 1 is that the arrangement of matching resistors and coupling capacitors on the back of the substrate is different. In this embodiment, as Figure 4b ,

[0049] Coupling capacitor 1, coupling capacitor 2, coupling capacitor 3, and coupling capacitor 4 are sequentially arranged along the x direction of the substrate and mounted on the back of the substrate. Matching resistor 1, matching resistor 2, matching resistor 3, and matching resistor 4 are also sequentially arranged along the The x direction of the substrate is arranged and attached to the back of the substrate; eight metallized wires are arranged along the y direction of the substrate (in other embodiments, part of the y direction and part of the x direction can be arranged); The metallized vias are respectively the first metallized via 21, the second metallized via 22, the third metallized via 23 and the fourth metallized via 24. The first metallized via hole 21, the second metalli...

Embodiment 3

[0051] The difference between this embodiment and embodiment one or embodiment two is that, as Figure 4c As shown, the front side of the substrate in this embodiment does not include a filter capacitor, and the pads in the gain region are connected to the outside of the substrate through a metallized wire and a gold wire in turn; the filter capacitor can be located on other substrates to achieve noise filtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com