Wave-regulating resistor and manufacturing process thereof

A wave-tuning resistor and resistance wire technology, applied in the direction of resistors, resistor parts, winding resistor elements, etc., can solve the problems of physical and mental health of employees, high dependence on manual operation, and high labor intensity of employees, etc., to achieve Good market application prospects, considerable economic benefits, and strong product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

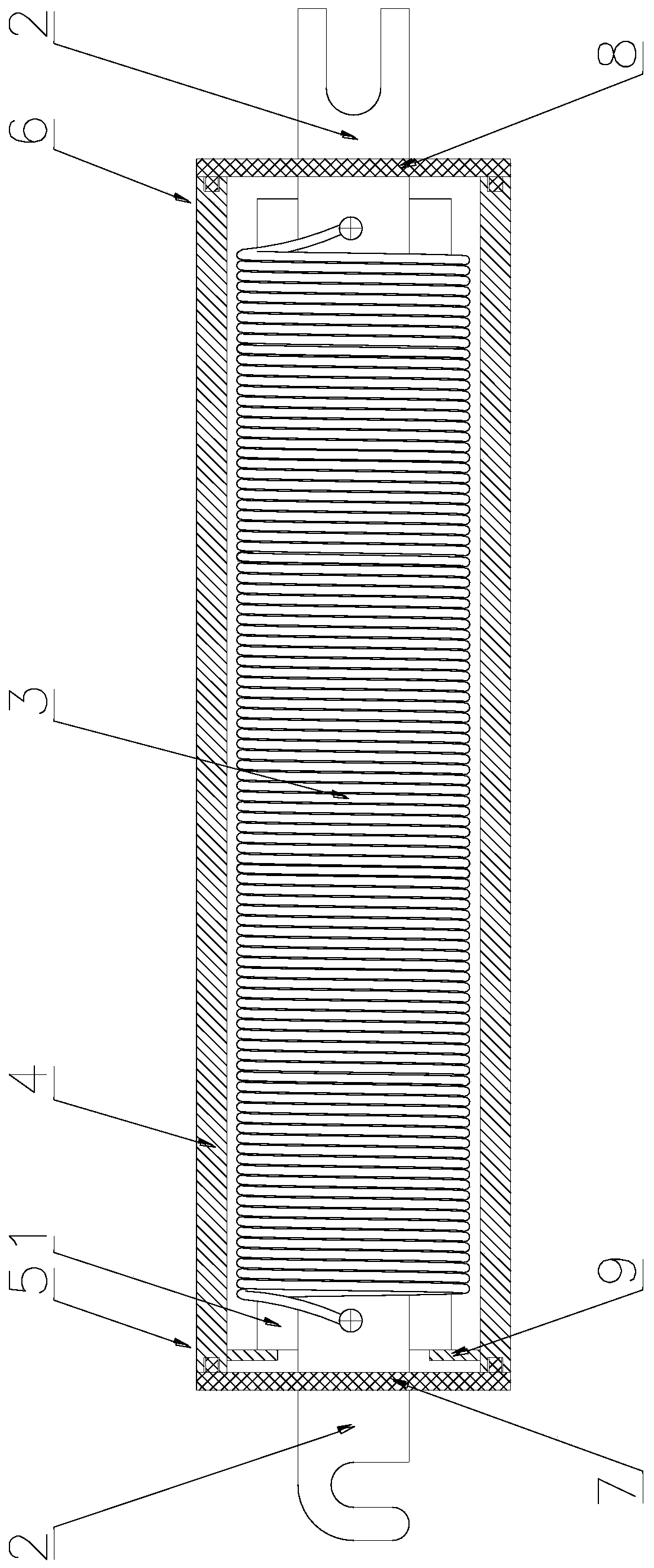

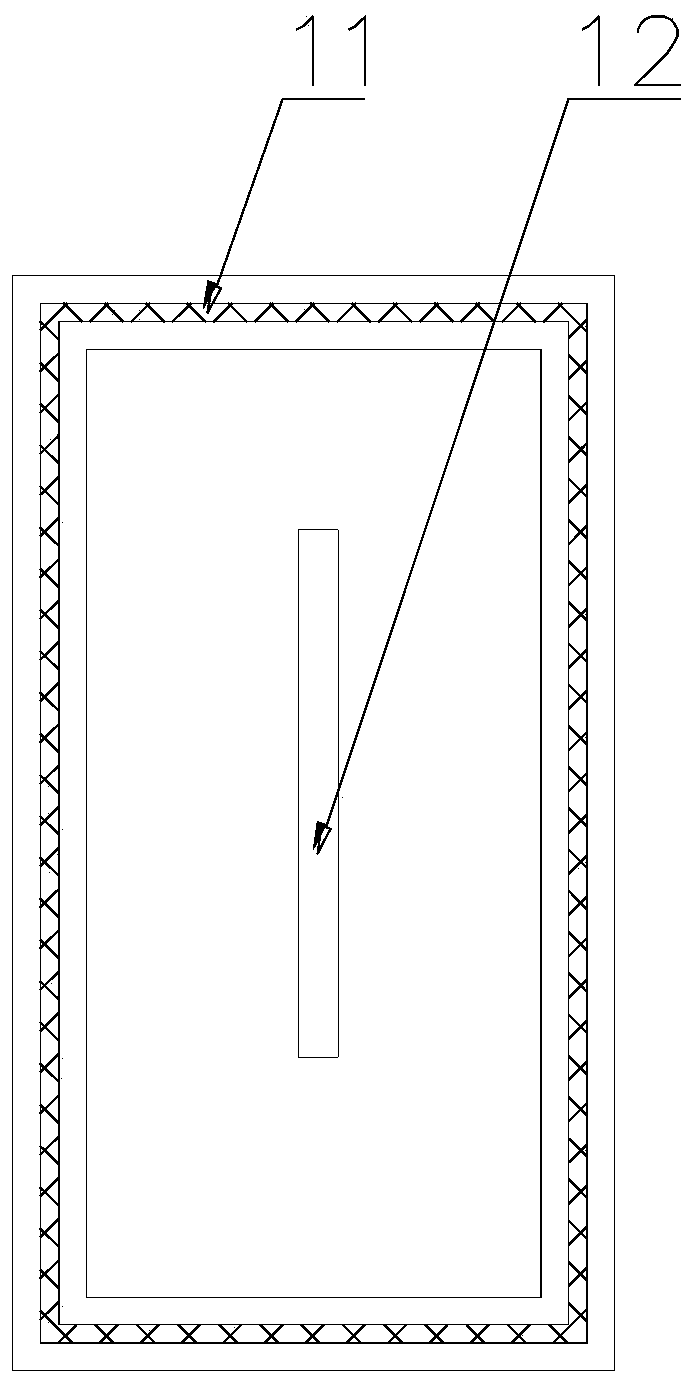

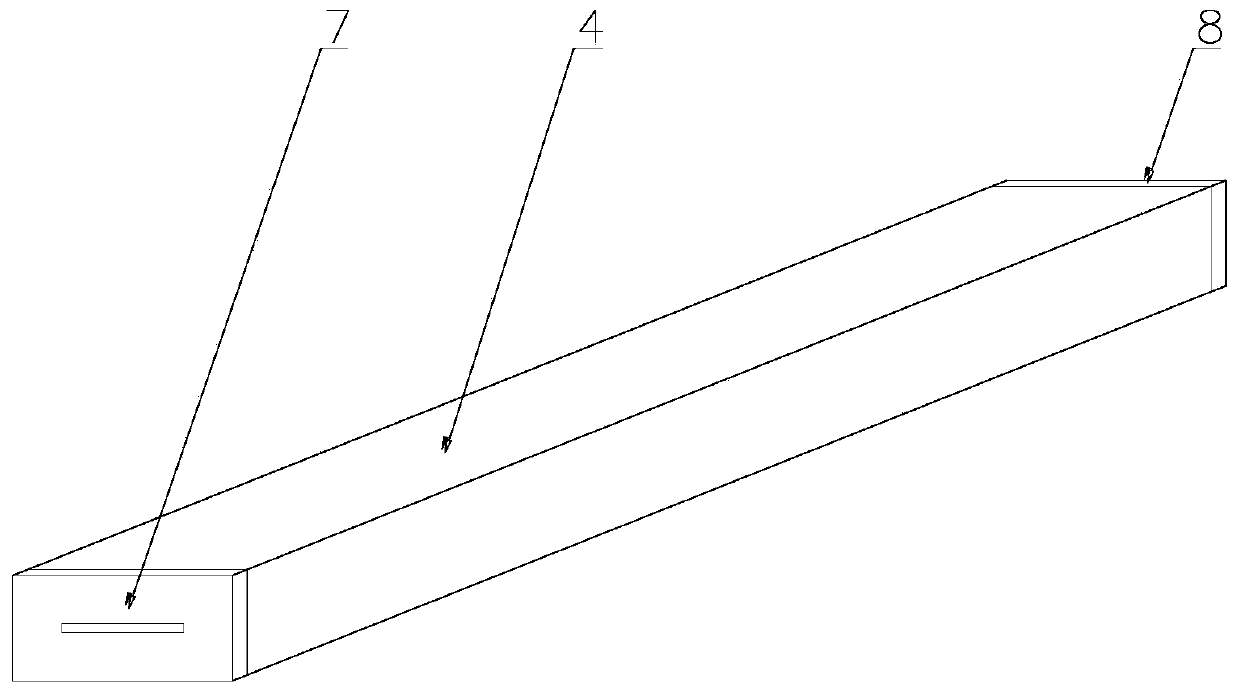

[0067] This embodiment includes a base part and a packaging case for encapsulating the base part; the base part includes an epoxy board frame 1, a conductive plate 2 fixed to both ends of the epoxy board frame 1, wound around the epoxy board frame 1, and connected to the conductive plate 2 resistance wire 3 forming a good electrical connection; the package housing includes a hollow body 4 and an end cap that covers the hollow body 4, the base part is hidden in the package housing, and its two conductive plates 2 protrude from both ends of the cover. The electronic potting glue that integrates the base part, the hollow body 4 and the cover is potted in the packaging shell, and the electronic potting glue is an electronic potting glue that is in a hard state after curing. In this embodiment, a position-limiting structure is provided in the hollow body 4 to limit the position of the epoxy board frame 1 , and the position-limiting structure is the position-limiting protrusion 9 . ...

Embodiment 2

[0079] In this embodiment, on the basis of Embodiment 1, a contact protrusion 14 is designed on the inner side of the airtight end cap 7 and the sealing end cap 8 to facilitate the contact between the end cap and the electronic potting glue, that is, the contact protrusion can be completely immersed in the electronic potting. Inside the sealant. The electronic potting glue in this embodiment is hard epoxy resin glue at room temperature. After curing, the hard epoxy resin glue at room temperature has very high mechanical strength, which can effectively ensure the structural strength of the product and the durability of the product.

[0080] In addition, a groove 13 is provided on the inner wall of the hollow body 4 to facilitate the flow of the electronic encapsulant. When the resistance value of the wave tuning resistor is relatively high, the thickness of the enameled wire wound will increase, and the increase in thickness will inevitably affect the space in the hollow body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com