Material with blue light prevention function and protective film applying same

A technology of anti-blue light and protective film, applied in the field of optical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

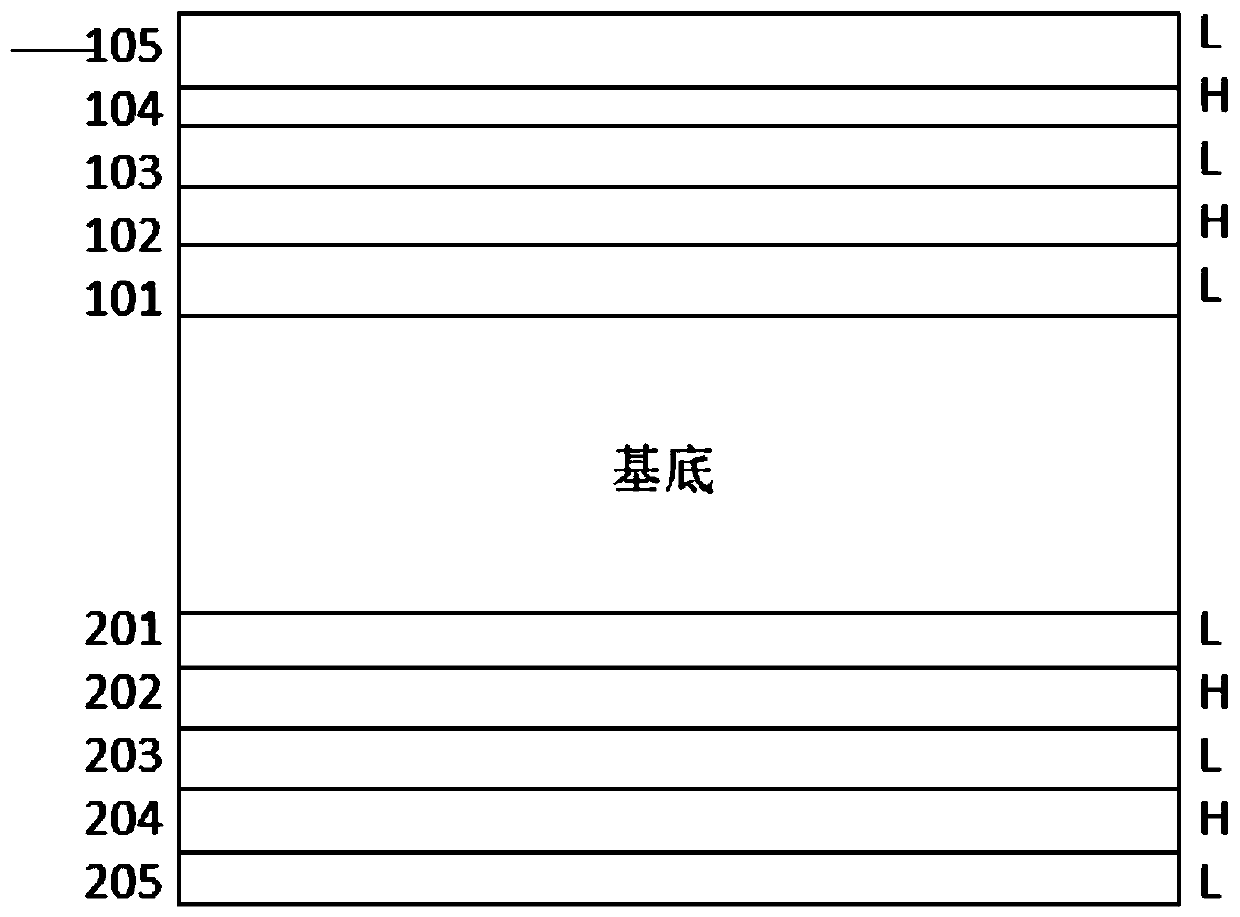

[0065] A broadband AR protective film with anti-blue light function, which includes a base 3, on which a high-refractive-index film layer made of a high-refractive-index material and a low-refractive-index film layer made of a low-refractive index material are arranged on the base 3 . Picture 1-1 It is a schematic diagram of the structure of the anti-blue light film of Example 1. The film layer in the figure is only a schematic diagram of the number of layers, and does not represent the actual thickness of the film layer.

[0066] The base of embodiment 1 adopts PC lens (polycarbonate), which has the advantages of excellent impact resistance, high refractive index, light specific gravity and 100% UV protection. Of course, according to needs, the substrate can also use polyethylene terephthalate (PET), cellulose triacetate (TAC), polymethyl methacrylate (PMMA), polycarbonate / polymethyl methacrylate Composite (PC / PMMA), polyimide (PI), polypropylene (PP), polyvinyl chloride (P...

Embodiment 2

[0081] A broadband AR protective film with anti-blue light function, it differs from Embodiment 1 in that: the PC lens is provided with a low refractive index material SiO 2 layer, the low refractive index material SiO 2 Layer with high refractive index material Cr 2 o 3 In this way, the high and low refractive index material film layers are arranged alternately, and a total of five layers are required on one side. From the front of the substrate, the anti-blue light film consists of a first low-refractive index film layer 101, a second high-refractive index film layer 102, a third low-refractive index film layer 103, a fourth high-refractive index film layer 104, The fifth low refractive index film layer 105 . The substrate adopts a double-sided symmetrical structure, and the anti-blue light film consists of the first low-refractive index film layer 201, the second high-refractive-index film layer 202, the third low-refractive index film layer 203, and the fourth high-refr...

Embodiment 3

[0091] A broadband AR protective film with anti-blue light function, it differs from Embodiment 1 in that: the PC lens is provided with a low refractive index material SiO 2 layer, the low refractive index material SiO 2 Layer with high refractive index material Cr 2 o 3 Layers, such high and low refractive index material film layers are arranged alternately, the fifth layer is MgF 2 . From the front of the substrate, the anti-blue light film consists of a first low-refractive index film layer 101, a second high-refractive index film layer 102, a third low-refractive index film layer 103, a fourth high-refractive index film layer 104, Layer 5 MgF 2 Layer 105. The substrate adopts a double-sided symmetrical structure, and the anti-blue light film consists of the first low-refractive index film layer 201, the second high-refractive-index film layer 202, the third low-refractive index film layer 203, and the fourth high-refractive-index film layer from the back of the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com