External expansion type soluble bridge plug

An expansion type, bridge plug technology, applied in the fields of petroleum exploration and oilfield development, can solve the problems of low material strength and unreliable sealing, and achieve the effect of good sealing effect, firm setting, and reduction of processing difficulty and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

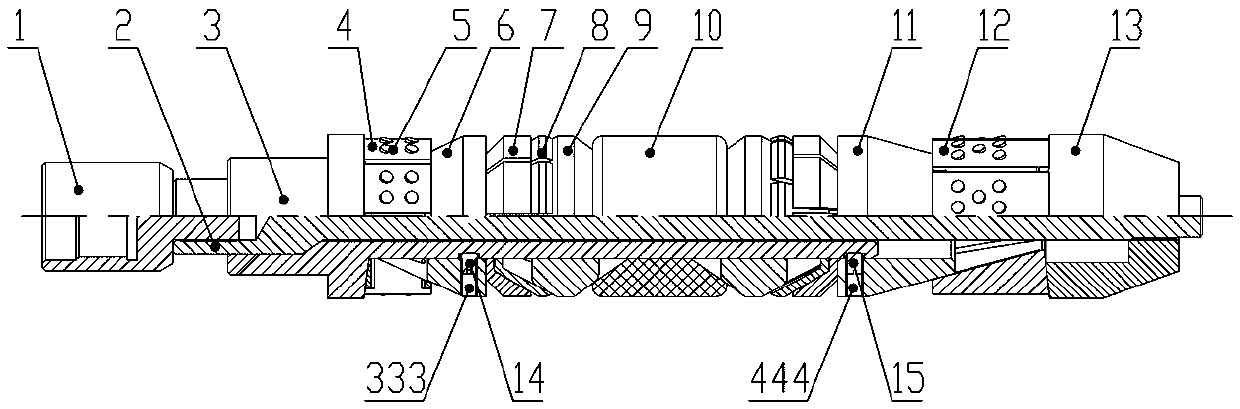

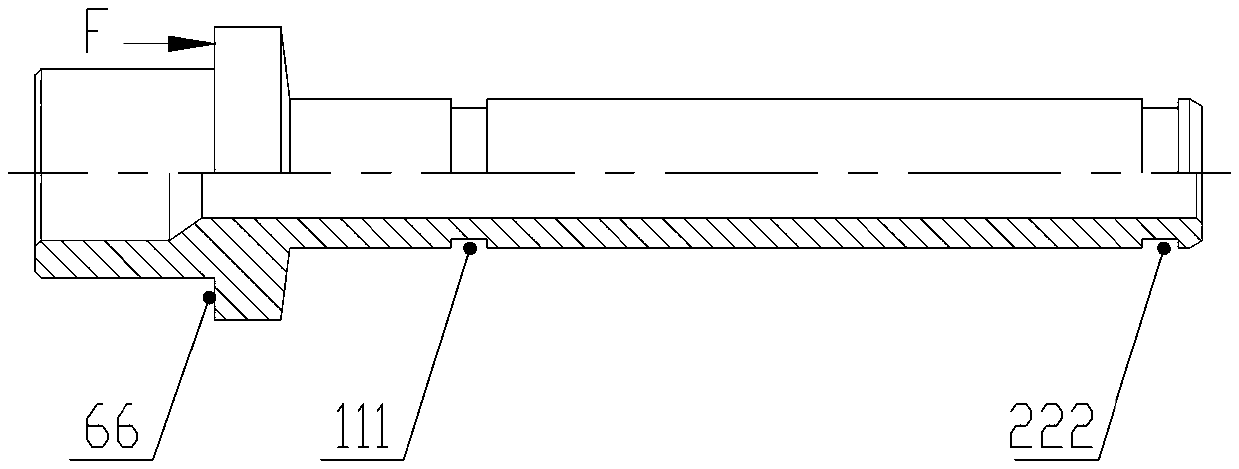

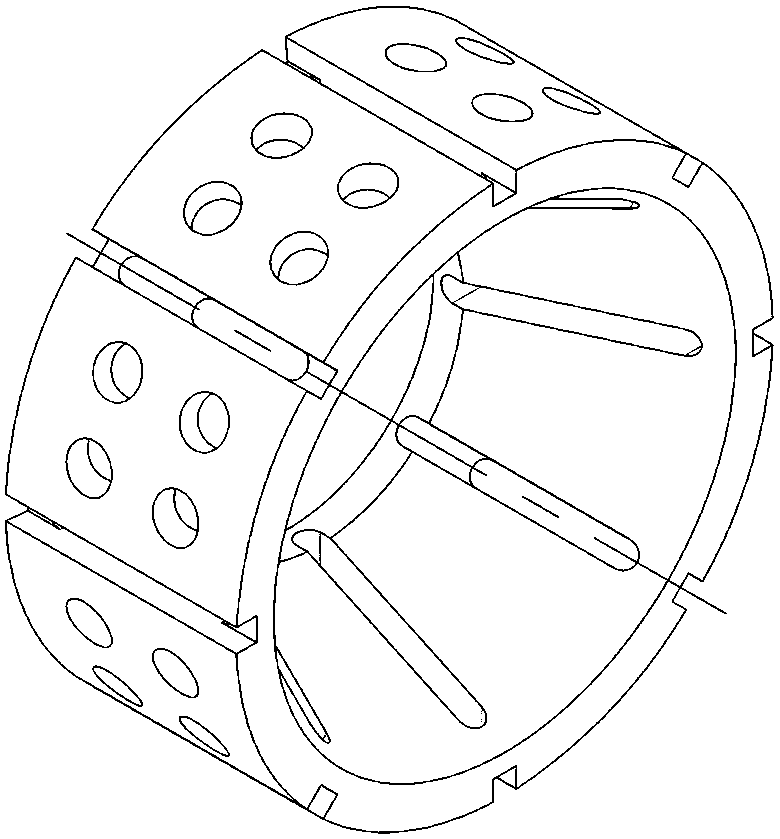

[0021] Embodiment 1, with reference to attached figure 1 , an externally expandable soluble bridge plug mentioned in the present invention, including a connector 1, a tie rod 2, a central tube 3, an upper slip seat 4, a slip tooth 5, an upper cone 6, a first retaining ring 7, The second retaining ring 8, the double setting cone 9, the external expansion rubber cylinder 10, the lower cone 11, the lower slip seat 12, the base 13, the first pin 14 and the second pin 15; Internal thread, the lower end of the connector 1 is threadedly connected with the upper end of the tie rod 2, and the center tube 3 is set on the outside of the tie rod 2. The upper part of the center tube is processed with a first pin ring groove 111, and the lower part of the center tube 3 is processed with a second pin ring groove. 222, the center pipe 3 is equipped with an upper slip seat 4, an upper cone 6, a first retaining ring 7, a second retaining ring 8, a double-sealing cone 9, an external expansion ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com