Building structure convenient to fabricate

A technology of building structure and fixing plate, applied in building structure, construction and other directions, can solve problems such as troublesome assembly, and achieve the effect of convenient and fast installation, solving inconvenient handling, inconvenient assembly, and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

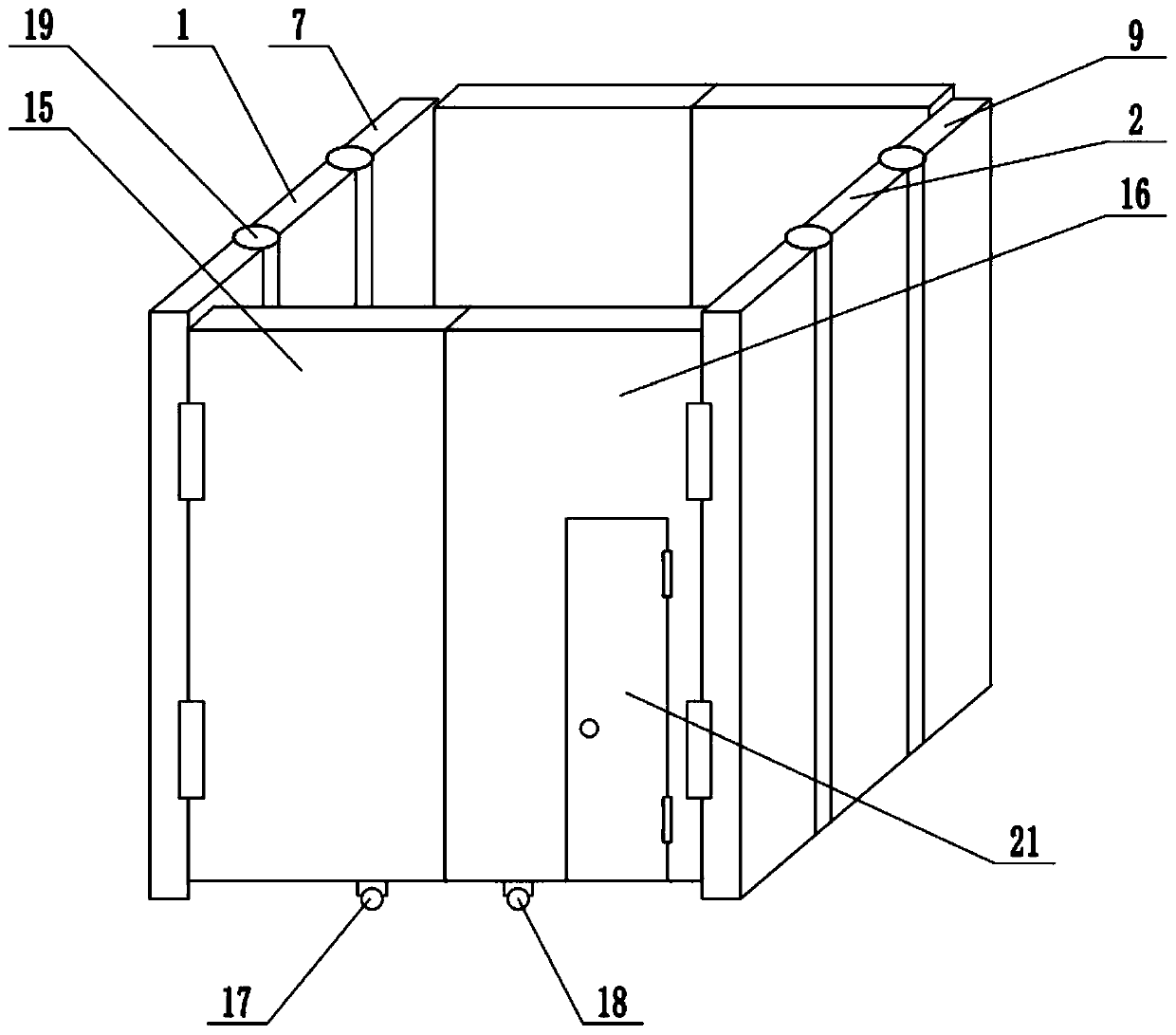

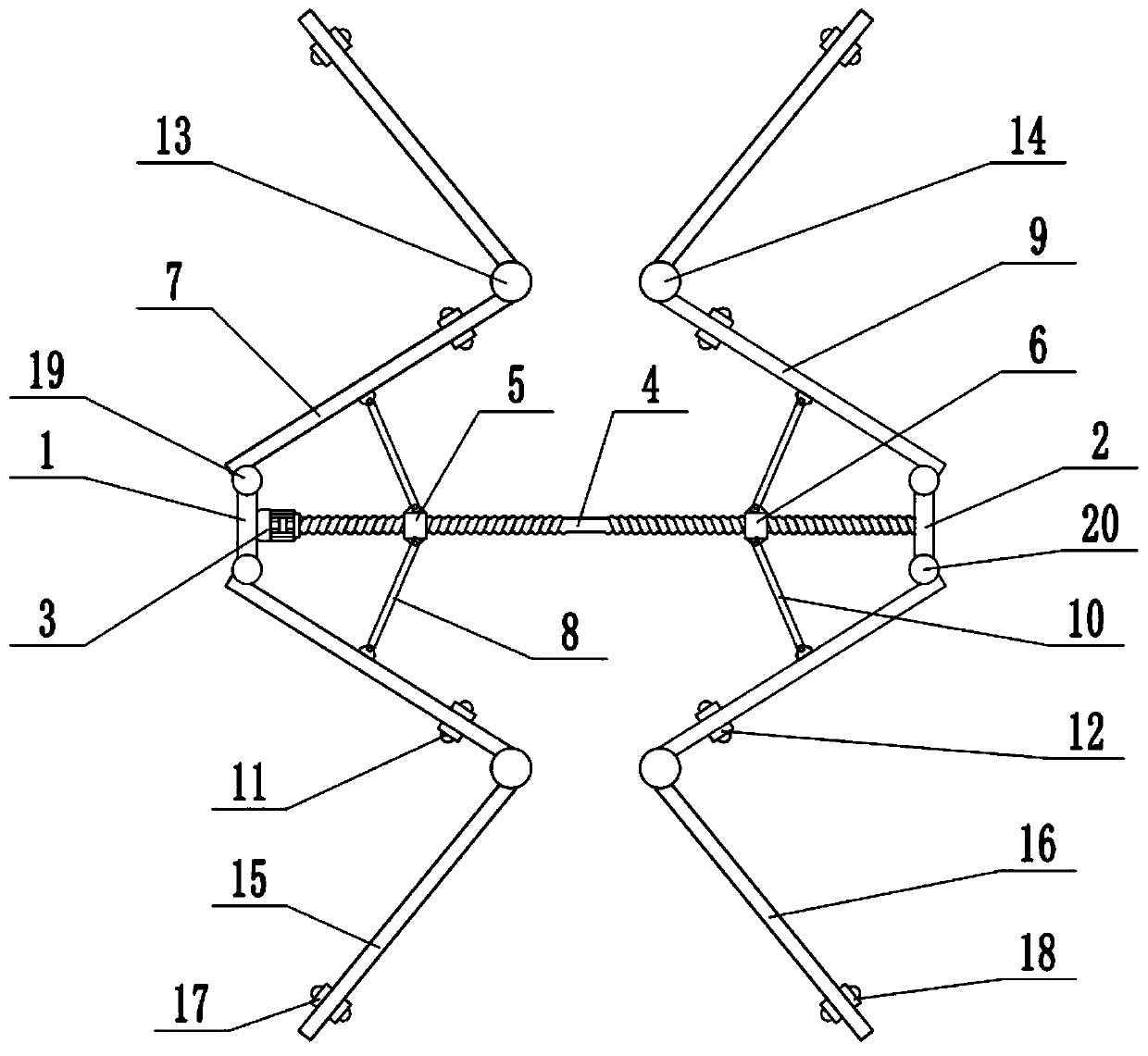

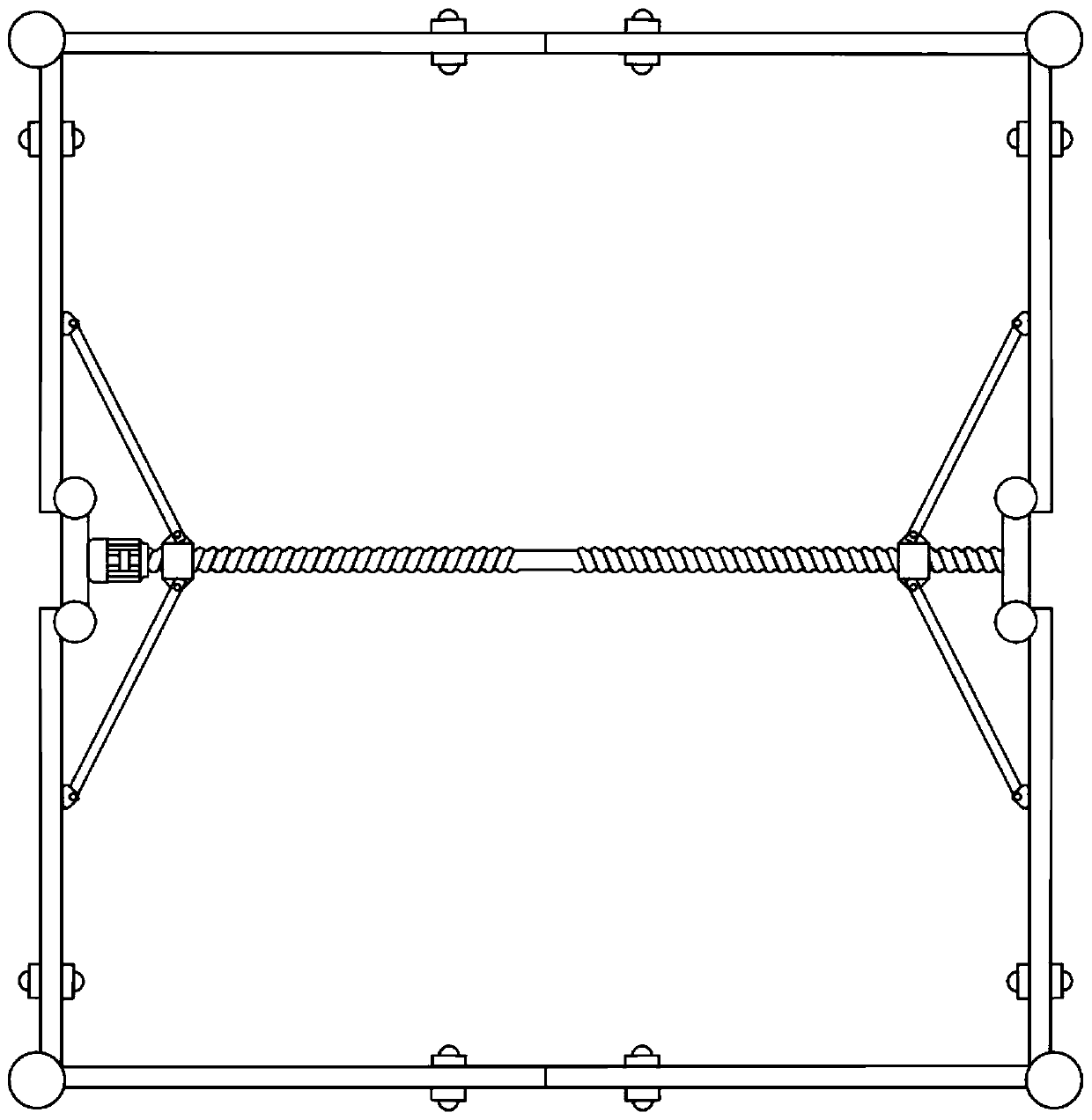

[0023] see Figure 1-3 , in an embodiment of the present invention, a building structure that is easy to assemble includes a left fixed plate 1, a right fixed plate 2 and a top plate 22, and a drive motor 3 is fixedly connected to the side wall of the left fixed plate 1, and the drive motor 3 is forward and reverse Motor, the shaft extension end of drive motor 3 is fixedly connected with two-way screw mandrel 4, and the right end of two-way screw mandrel 4 is rotationally connected with the side wall of right fixed plate 2, and left slide block 5, right slide block are sheathed on two-way screw mandrel 4 6. The left slider 5 and the right slider 6 are threadedly connected with the two-way screw rod 4 respectively. The left slider 5 and the right slider 6 are arranged symmetrically. 7 is rotationally connected with the left fixed plate 1 by the left support shaft 19, the left support plate 7 can rotate freely, the left support roller 11 is installed on the bottom of the left su...

Embodiment 2

[0025] please read Figure 1-5 , a building structure that is easy to assemble, including a left fixed plate 1, a right fixed plate 2 and a top plate 22, a drive motor 3 is fixedly connected to the side wall of the left fixed plate 1, the drive motor 3 is a forward and reverse motor, and the drive motor 3 The end of the shaft extension is fixedly connected with a two-way screw rod 4, the right end of the two-way screw rod 4 is rotatably connected with the side wall of the right fixed plate 2, and the two-way screw rod 4 is provided with a left slider 5, a right slider 6, and a left slider 5 , right slide block 6 are threadedly connected with two-way screw mandrel 4 respectively, left slide block 5, right slide block 6 are arranged symmetrically, left support plate 7 is all installed at the two ends of left fixed plate 1, and left support plate 7 passes through left support shaft 19 Rotately connected with the left fixed plate 1, the left support plate 7 can rotate freely, the ...

Embodiment 1、 Embodiment 2

[0026] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: when the present invention needs to be assembled, start the drive motor 3, drive the two-way screw mandrel 4 to rotate, and drive the left slider 5 and the right slider 6 to move backwards, Thereby driving the left support plate 7 and the right support plate 9 to open outwards, the two left support plates 7 and the left fixed plate 1 form a wall, symmetrically, the two right support plates 9 and the right fixed plate 2 form another wall face, push the left movable plate 15, drive the left movable plate 15 to rotate around the left rotating shaft 13, rotate the left movable plate 15 to a position perpendicular to the left supporting roller 11, push the right movable plate 16, and drive the right movable plate 16 to rotate The right shaft 14 rotates, the right movable plate 16 is rotated to the position perpendicular to the right support roller 12, the top plate 22 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com