Honeycomb H-shaped steel beam connected by bolts and manufacturing method

A manufacturing method and bolt technology, applied in the direction of girders, joists, trusses, etc., can solve the problems of no expansion of honeycomb beams, high welding cost, welding pollution, etc., and achieve increased expansion ratio, high bearing capacity, and no welding pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

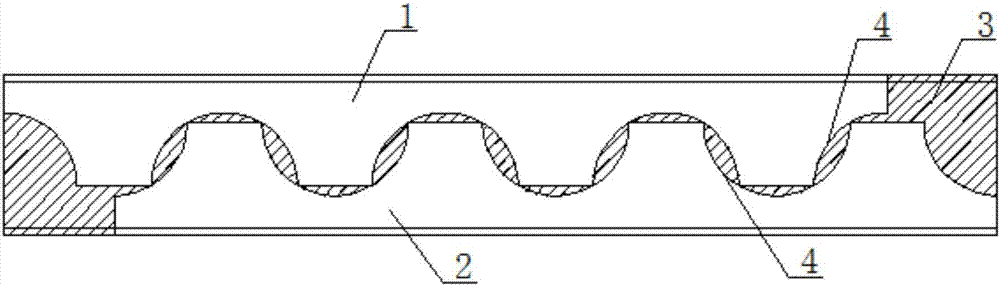

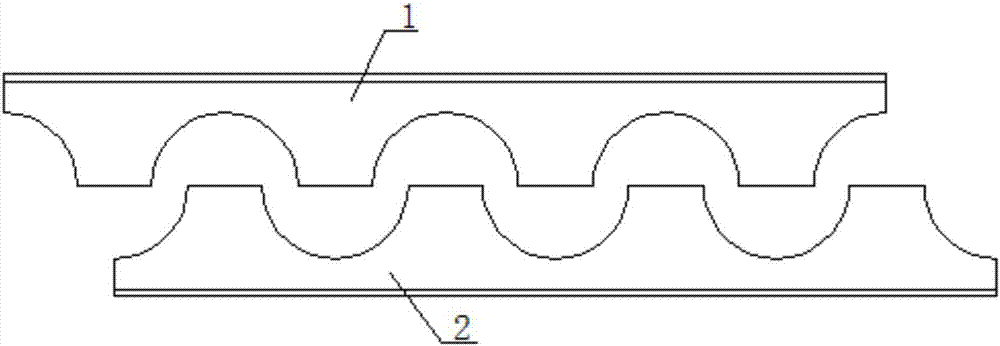

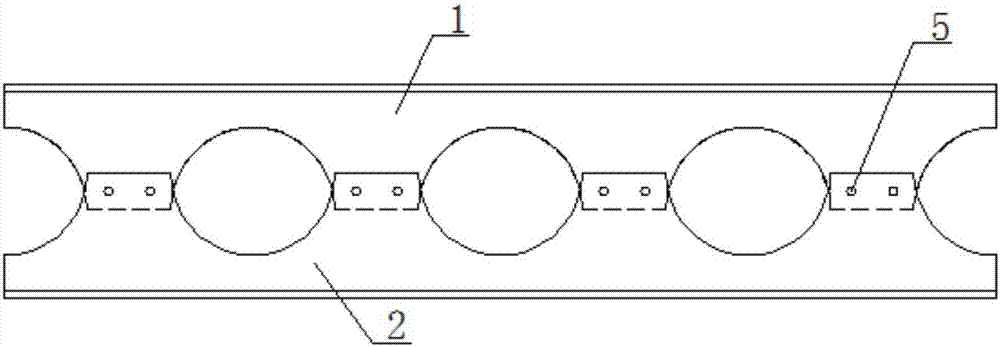

Embodiment 1

[0066] A bolted honeycomb H steel beam such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it is a honeycomb steel beam with horizontal oblong holes, including an upper T-shaped beam 1, a lower T-shaped beam 2, and bolts 5. The manufacturing method is carried out according to the following steps: first, the web of the H-shaped steel beam is figure 1 The cutting line 4 shown in the figure is cut to obtain figure 2 For the upper and lower T-beams shown, bolt holes are made at the crests of the webs of the upper and lower T-beams, where the webs of the upper and lower T-beams have flanges Parallel cut the straight section, and then displace the cut straight section of the upper T-beam web and the cut straight section of the lower T-beam web, keep the straight line parallel and align the two ends, and then use high-strength bolts for lap connection The inter-hole web is formed, and the honeycomb steel beam with horizontal long round holes is finally obtained. The H...

Embodiment 2

[0068] A bolted honeycomb H steel beam such as figure 1 , figure 2 , Figure 5 , Image 6 As shown, it is a circular-hole honeycomb beam, including an upper T-shaped beam 1, a lower T-shaped beam 2, a bolt 5, and a spliced cover plate 6. Bolt holes are made at the cover plate, and high-strength bolts are used to connect the upper and lower T-beam webs with a single-side spliced cover plate. For other references to Embodiment 1, details are not repeated here.

Embodiment 3

[0070] A bolted honeycomb H steel beam such as figure 1 , figure 2 , Figure 7 , Figure 8 As shown, it is a vertical oblong hole honeycomb steel beam, including an upper T-shaped beam 1, a lower T-shaped beam 2, a bolt 5, and a splicing plate 6. The width of the splicing cover plate is the same as that of the upper and lower T-shaped beam webs The length of the cutting straight line section is the same, bolt holes are made at the crests of the upper and lower T-beam webs and the spliced cover plate, and high-strength bolts are used to connect the upper and lower T-beam webs with the help of a single-side spliced cover plate. In this embodiment, the section height of the honeycomb steel beam is increased by splicing the cover plate on one side. For other references to Embodiment 1, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com