A high-performance seamless continuous pipe and its manufacturing method

A manufacturing method and technology for coiled tubing, applied in the field of oil and natural gas pipes, can solve problems such as failure of pipes, and achieve the effects of reducing center segregation, improving the quality of steel belt joints, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

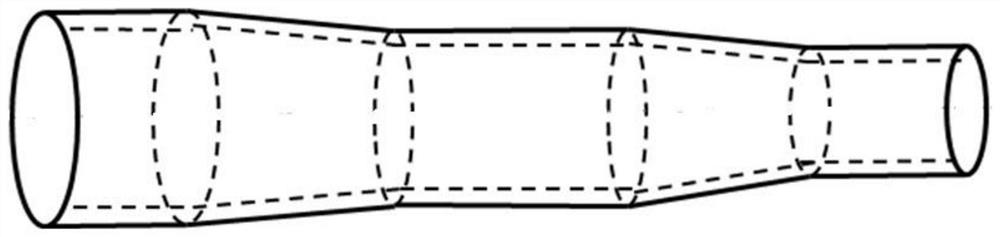

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] Through the Φ73×3.8mm tube billet, three geometric shapes of CT90 steel grade high-performance seamless continuous tubes are manufactured. The main manufacturing steps are as follows:

[0027] The mass percentage of the chemical composition of the plate is as follows: C: 0.1%; Si: 0.35%; Mn: 0.5%; P: 0.005%; S: 0.0008%; Cu: 0.45%; Cr: 0.65%; 0.3%; Ti: 0.015%; Nb: 0.03%, the rest is Fe and unavoidable impurities.

[0028] 1. Pre-desulfurize the molten iron, smelt, alloy, LF+RH, and Ca, and continuously cast it into a slab with a thickness of 100mm; heat it to 1200°C for rough rolling, and finish rolling at 780-860°C to 3.8mm, pickling, finishing Finishing and crimping are used for pipe making, and coiling is performed at 450-550°C.

[0029] 2. Coil slitting and lengthening

[0030] The coil is slit into steel strips with a width of 226mm, and the ends of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com