Method for adjusting air-fuel ratio of annealing furnace

An annealing furnace and air-fuel ratio technology, applied in the field of metallurgy, can solve problems such as abnormal air and gas flow balance in the furnace area, and achieve the effects of reducing heat loss, prolonging service life, and reducing physical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

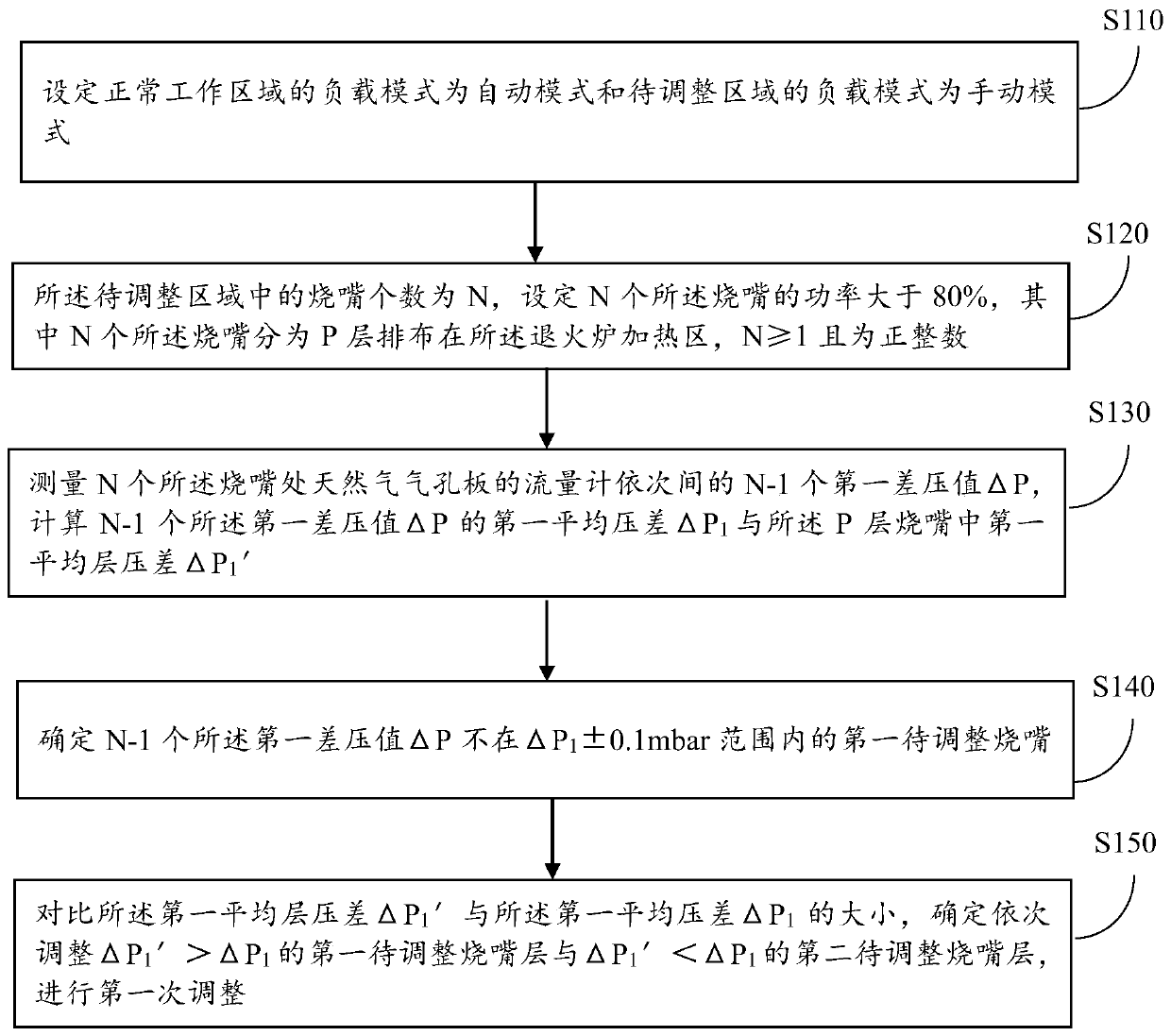

[0021] The embodiment of the present invention provides a method for adjusting the air-fuel ratio of the annealing furnace, please refer to figure 1 , the method includes steps 110 to 150:

[0022] Step 110: set the load mode of the normal working area to automatic mode and the load mode of the area to be adjusted to manual mode;

[0023] Step 120: The number of burners in the area to be adjusted is N, and the power of the N burners is set to be greater than 80%, wherein the N burners are divided into P layers and arranged in the annealing furnace for heating area, N≥1 and is a positive integer.

[0024] Specifically, the method of adjusting the air-fuel ratio of the annealing furnace in the embodiment of the present application is implemented under the normal production of the annealing furnace. The pressure value of the burner is adjusted. Divide the burners in the heating zone of the annealing furnace into M areas, wherein the M areas include the normal working area and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com