Electrified grounding fault searching unmanned aerial vehicle and matched hoisting bin device

A ground fault and unmanned aerial vehicle technology, which is applied to measurement devices, unmanned aerial vehicles, motor vehicles, etc., can solve the problems of high labor intensity, low operation efficiency, waste of human and financial resources, etc., and achieve the effect of strong mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

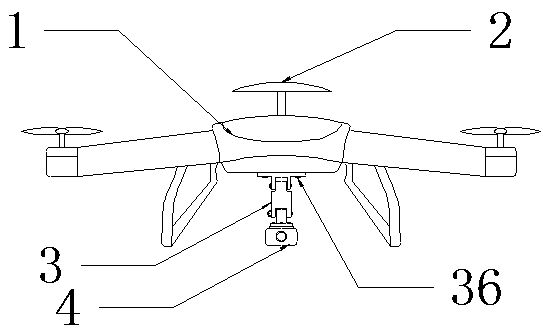

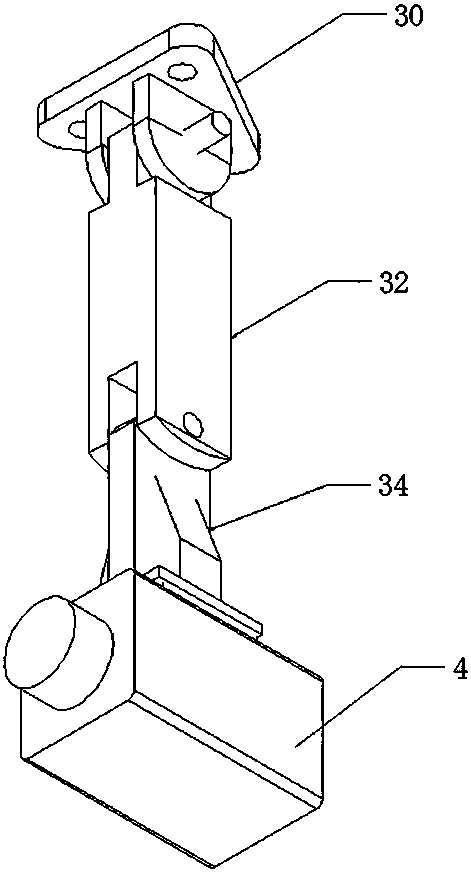

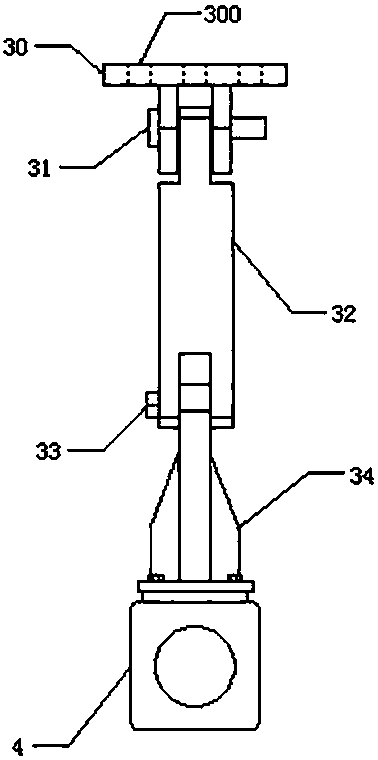

[0021] Such as Figure 1-7 As shown, a live grounding fault search UAV 1 and supporting hanger device, it includes a UAV 1, the upper part of the UAV 1 is connected with a data transmission module 2, the UAV 1 The lower end is connected with a suspension bracket 3, and the suspension bracket 3 includes a connecting block 30, a first connecting rod 32, a second connecting rod 34 and a fixed platform 35, and the connecting block 30 is provided with a connecting hole 300. The connecting hole 300 passes through the bolt 36 and is connected to the UAV 1, the lower end of the connecting block 30 is connected to the second pin 33 through the first pin 31, and the lower end of the second pin 33 is connected through the second pin 33 The second connecting rod 34, the lower end of the second connecting rod 34 is connected with a fixed platform 35, the fixed platform 35 is provided with a fixed hole, and the bolt 36 is passed through the fixed hole and connected with the infrared detecti...

Embodiment 2

[0024] Such as Figure 1-7 As shown, a live grounding fault search UAV 1 and supporting hanger device, it includes a UAV 1, the upper part of the UAV 1 is connected with a data transmission module 2, the UAV 1 The lower end is connected with a suspension bracket 3, and the suspension bracket 3 includes a connecting block 30, a first connecting rod 32, a second connecting rod 34 and a fixed platform 35, and the connecting block 30 is provided with a connecting hole 300. The connecting hole 300 passes through the bolt 36 and is connected to the UAV 1, the lower end of the connecting block 30 is connected to the second pin 33 through the first pin 31, and the lower end of the second pin 33 is connected through the second pin 33 The second connecting rod 34, the lower end of the second connecting rod 34 is connected with a fixed platform 35, the fixed platform 35 is provided with a fixed hole, and the bolt 36 is passed through the fixed hole and connected with the infrared detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com