Construction method of drilling device for complex high and steep side slope

A drilling device and technology for high and steep slopes, applied in the field of geotechnical engineering, can solve problems such as hole position deviation, drill pipe breakage, and poor stability, and achieve enhanced stability and safety performance, high work efficiency, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

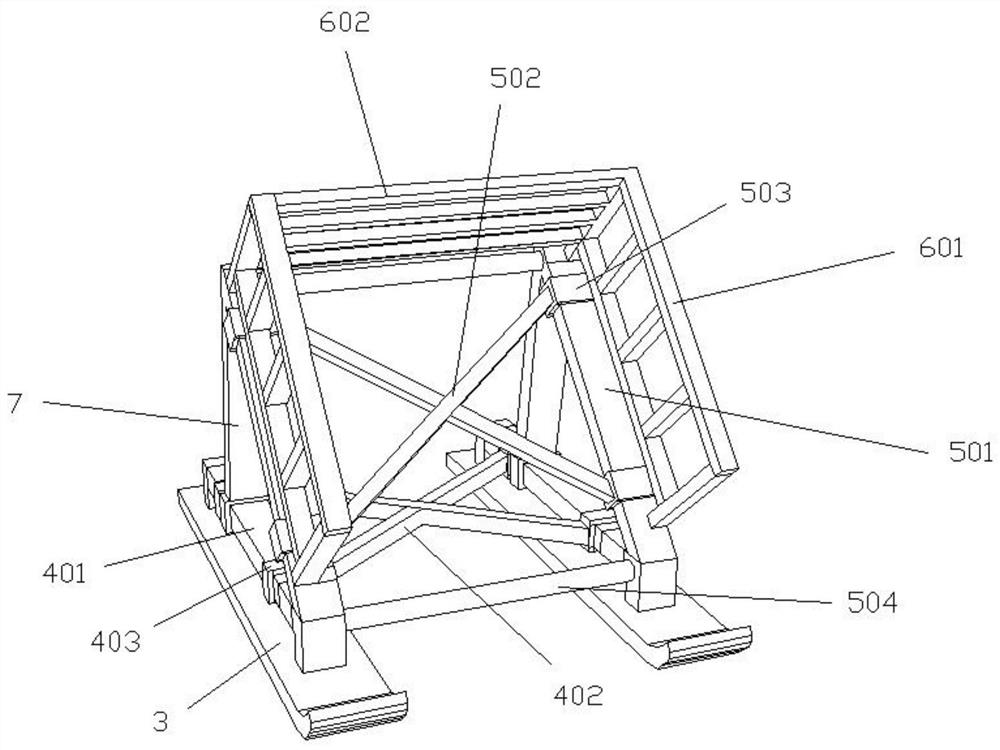

[0042] Such as Figure 1-5Shown, a kind of construction method of the drilling device of complex high steep slope, described drilling device comprises drilling machine support 1, drilling machine base 12 and drilling machine 2; Described drilling machine support 1 comprises slide plate 3, The chassis 4 and the platform 5 are arranged on the skateboard 3; the chassis 4 includes two chassis longitudinal steel pipes 401 parallel to the skateboard and a chassis cross steel pipe 402 sleeved on the chassis longitudinal steel pipes 401, and the chassis sleeve 403 passes through the The steel pipe 401 slides to realize the opening and closing of the cross steel pipe 402 of the chassis. The longitudinal steel pipe 401 of the chassis is fixedly connected to the slide plate 3. The platform 5 includes two platform longitudinal steel pipes 501 parallel to the slide plate 3 and a platform socketed on the platform longitudinal steel pipe 501. The cross steel pipe 502 and the front and rear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com