A Method for Eliminating Cracks in Gravity Casting

A technology to eliminate gravity and cracks, applied to casting molding equipment, molds, mold components, etc., can solve problems such as inconvenient demoulding, lower production efficiency, and cracking of thin-walled parts, so as to reduce the process of sand core making and reduce The effect of improving the defect rate and the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

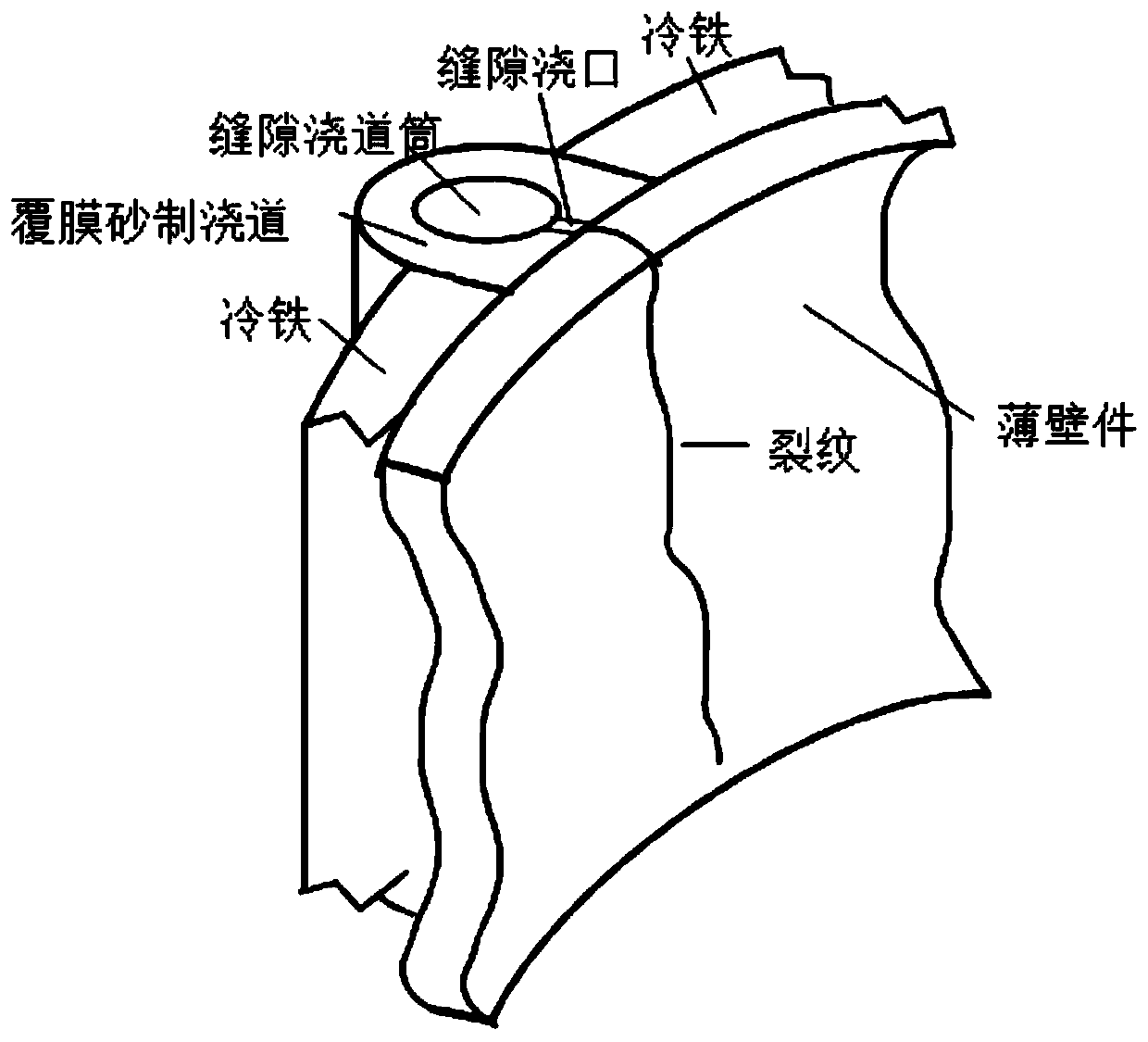

[0024] The present invention is a method for eliminating cracks in gravity casting, and its working principle is as follows figure 1 As shown, it includes: a slotted runner system made of ductile iron, which consists of two split metal flap molds to form a slotted runner barrel and a slotted gate, and the inner wall of the slotted runner barrel and the slotted gate is brushed with thermal insulation paint , the thermal insulation coating is made of the following raw materials according to weight percentage: 20% zinc oxide, 3% water glass, and 77% water; there is a limit block at the gap gate, and the limit block is set at the top and bottom of the gap gate. The thickness of the bit block is equal to the width of the gap; the aluminum alloy liquid enters the gap runner barrel from the bottom runner, and fills the thin-walled cavity through the gap gate in layers; At the barrel body, away from the edge of the thin wall, there is no crack source at the slot gate, thereby eliminat...

Embodiment 2

[0028] The present invention is a method for eliminating cracks in gravity casting, and its working principle is as follows figure 1 As shown, it includes: a slotted runner system made of ductile iron, which consists of two split metal flap molds to form a slotted runner barrel and a slotted gate, and the inner wall of the slotted runner barrel and the slotted gate is brushed with thermal insulation paint , the thermal insulation coating is made of the following raw materials by weight percentage: 20% zinc oxide, 65% asbestos powder and 15% water glass; there is a limit block at the gap gate, and the limit block is set at the top and bottom of the gap gate. The thickness of the limit block is equal to the width of the gap; the aluminum alloy liquid enters the gap runner barrel from the bottom runner, and fills the thin-walled cavity through the gap gate in layers; the solidification continues from the far end of the gap to the gap, and the hot spot area is in the gap At the sp...

Embodiment 3

[0030] The invention provides a method for eliminating cracks in gravity casting, comprising: adopting a gray cast iron slot runner system, the system includes two split metal flap molds to form a slot runner barrel, a slot gate, and a slot runner There are refractory felt cylinders built into the cylinder and the gap gate, and there are limit blocks at the gap gate. The limit blocks are set at the top and bottom of the gap gate. The thickness of the limit block is equal to the width of the gap; The channel enters the slot runner barrel, and fills the thin-walled cavity through the slot gate in layers; solidification continues from the far end of the slot to the gap, and the hot spot area is at the slot runner barrel, away from the edge of the thin wall, at the slot gate There is no source of cracks, thus eliminating cracks in castings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com