Punching machine and robot used for punching machine

A punching machine and robot technology, applied in the field of mechanical equipment, can solve the problems of dangerous punching work, waste of punching machine value, and safety, etc., and achieve the effects of multiple uses, high use value, and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

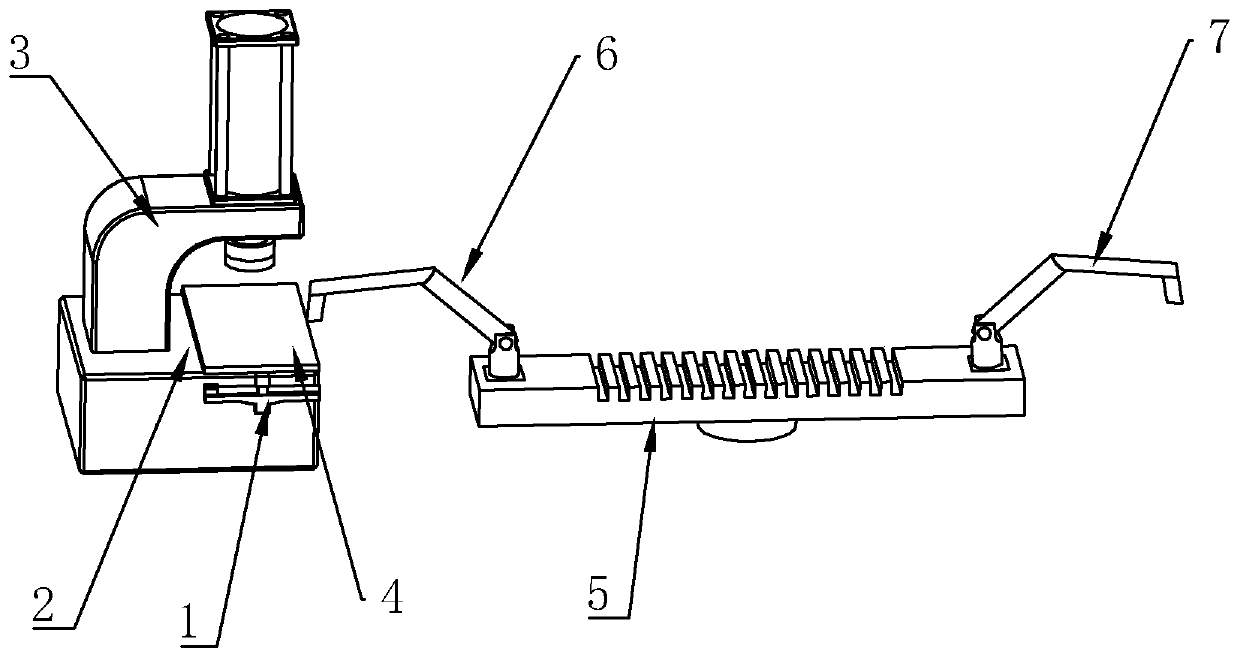

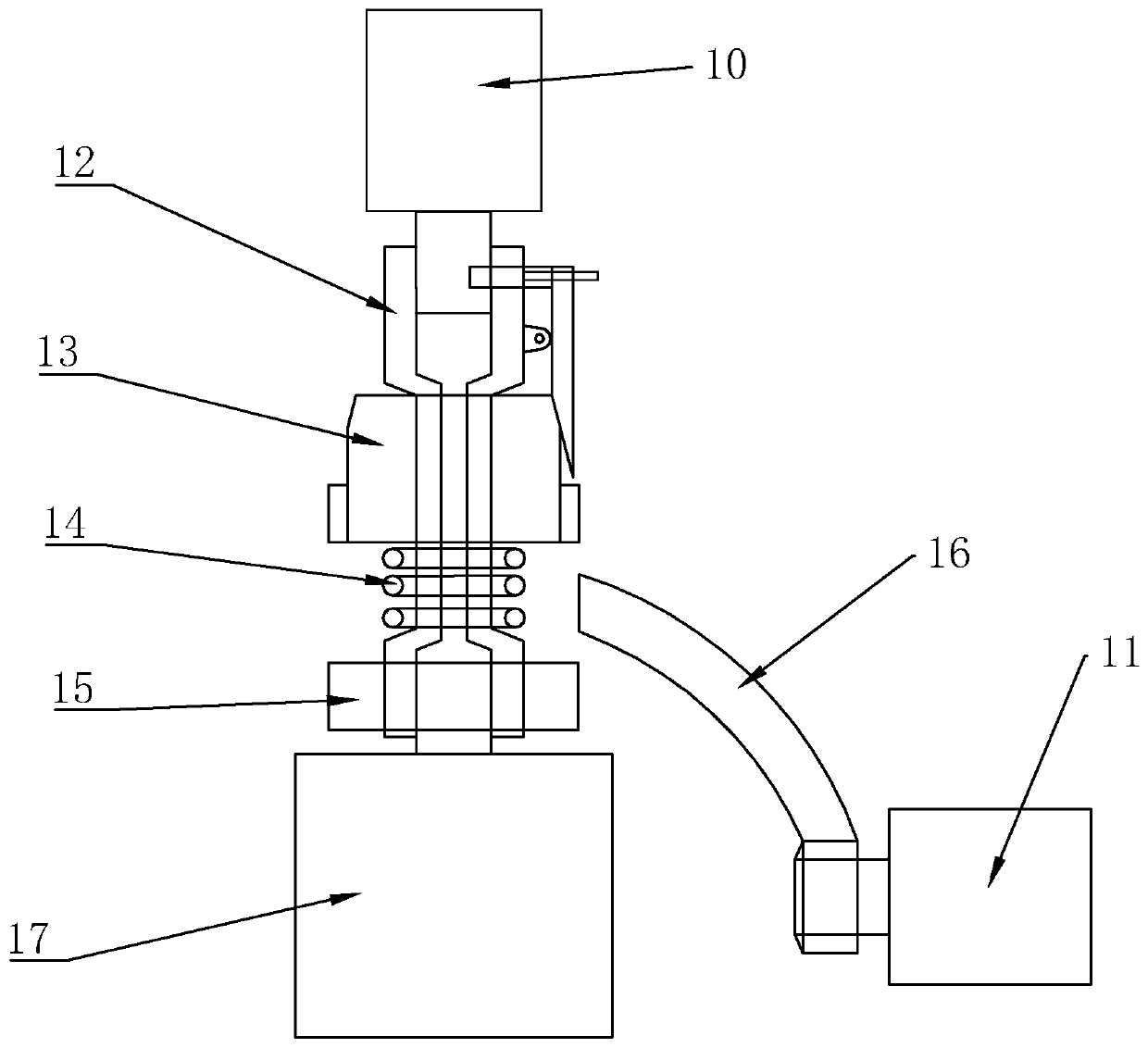

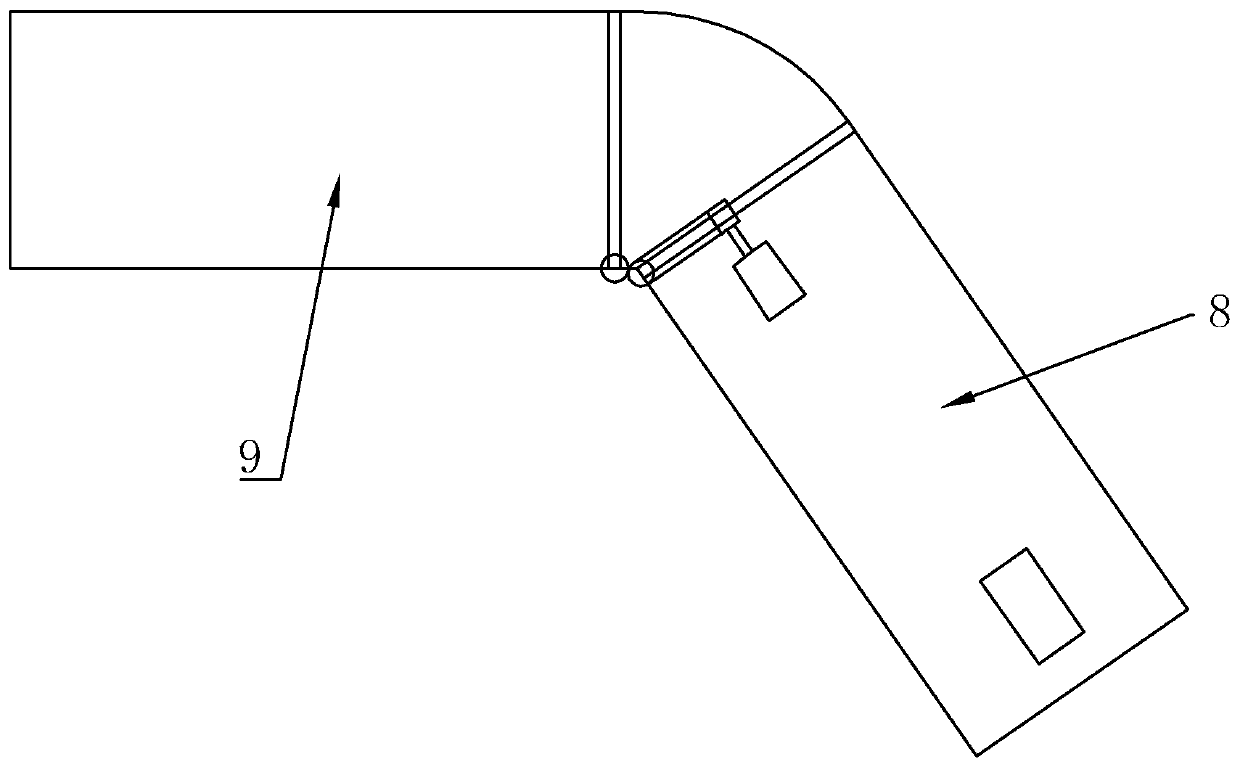

[0025] Refer to attached Figures 1 to 3 The punching machine of the present invention and the robot embodiment for the punching machine will be further described.

[0026] A stamping machine, comprising a faucet support 3, a first hydraulic cylinder and a travel switch, the faucet support 3 includes a cantilever and a workbench 2 below the cantilever, the first hydraulic cylinder is fixed on the cantilever, and the travel switch controls the piston of the first hydraulic cylinder The up and down telescopic and telescopic travel of the rod, the base plate 4 and the moving device 1 for translationally moving the base plate 4 are arranged on the workbench 2. The moving device 1 includes a T-shaped support frame, an X-axis moving mechanism and a Y-axis moving mechanism, and the X-axis moves The mechanism includes an X-axis motor, an X-axis screw and an X-axis screw seat. The X-axis motor is fixed at one end of the support frame. One end of the X-axis screw is fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com