Preparation method of Ag2S/TiO2 composite photocatalyst and application thereof

A catalyst and composite light technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unfavorable preparation methods and many kinds of raw materials, so as to simplify the preparation process, reduce the kinds of raw materials, The effect of preventing the loss of effective ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

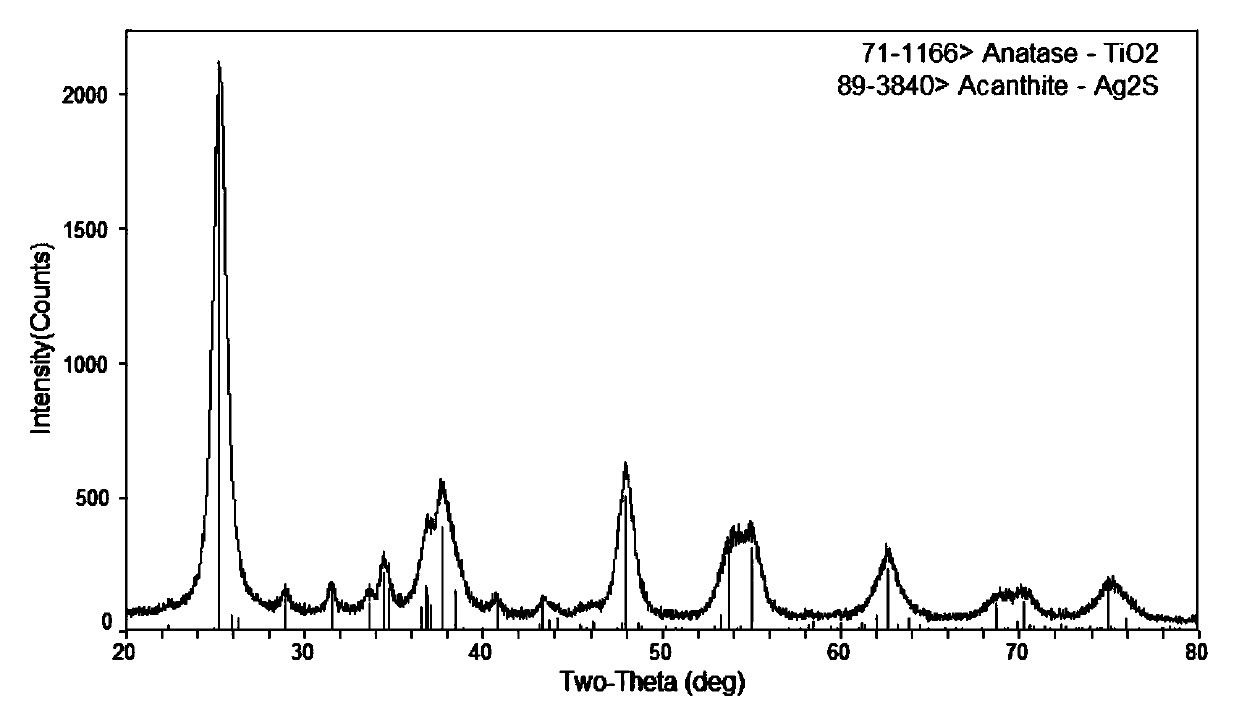

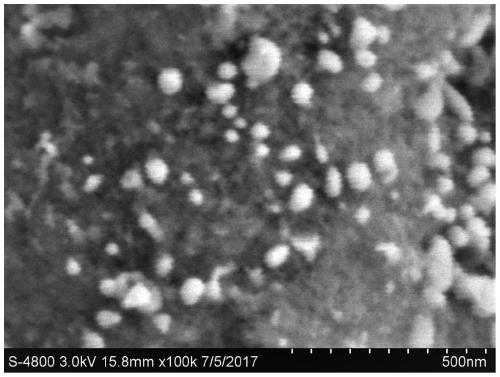

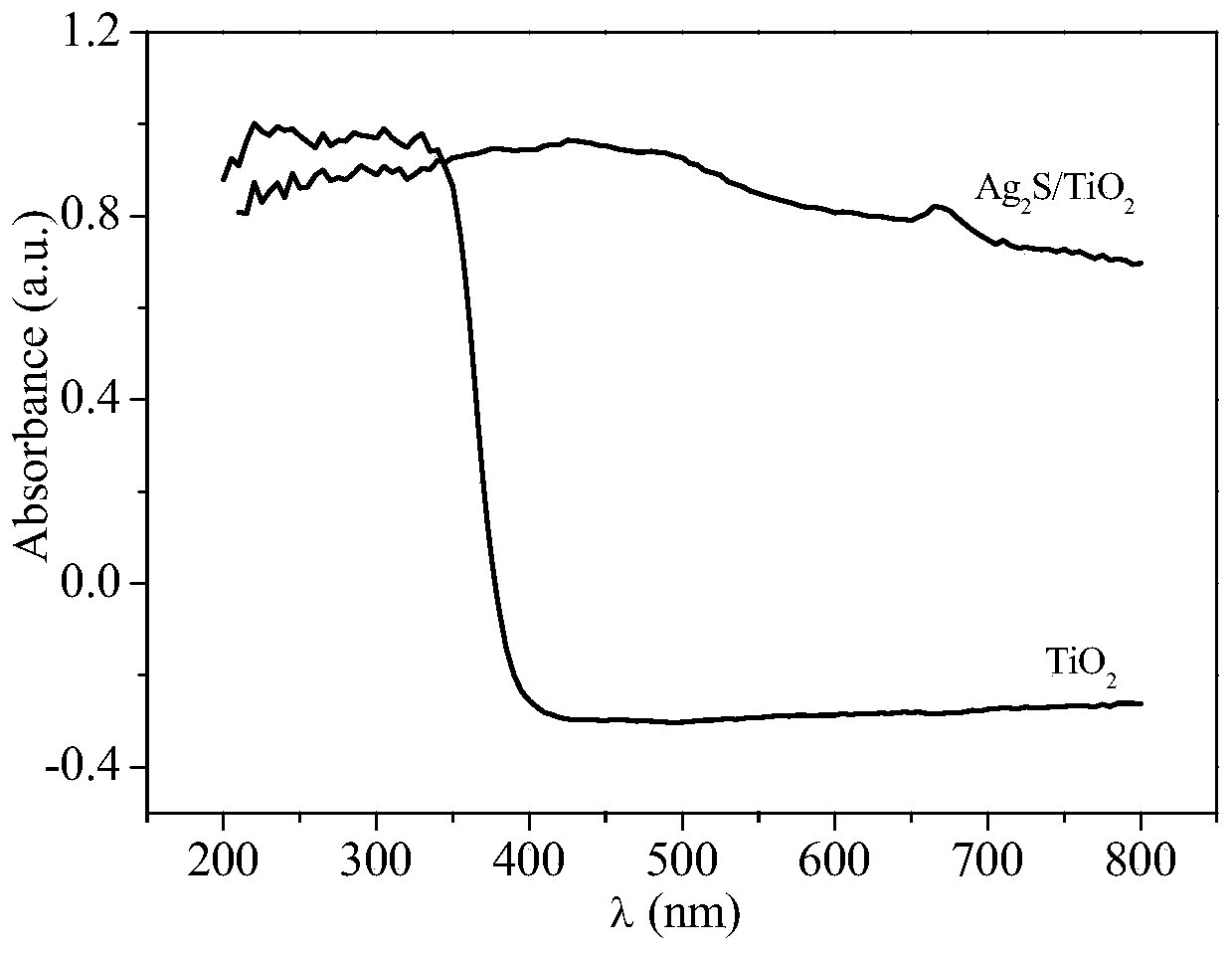

[0036] Ag of the present invention 2 S / TiO 2 The preparation method of the composite photocatalyst uses metatitanic acid and silver nitrate as raw materials, citric acid as a complexing agent for silver ions, and adopts sol-gel technology combined with a heat treatment process to prepare Ag 2 S / TiO 2 Composite photocatalyst; Concretely comprises the following steps:

[0037] Step 1: Mix silver nitrate, citric acid and deionized water evenly to obtain a mixed solution;

[0038] Step 2: Slowly add ammonia water dropwise to the mixed solution obtained in step 1, and stir to obtain a sol;

[0039] Step 3: Mix the sol obtained in Step 2 with metatitanic acid, disperse it ultrasonically, stir it magnetically, and then heat it in a water bath. After the system loses fluidity, dry it in a blast drying oven to obtain a precursor;

[0040] Step 4: heat-treat the precursor obtained in step 3 in a tube furnace under nitrogen flow protection to obtain Ag 2 S / TiO 2 composite photocata...

Embodiment 1

[0051] 1. Mix 0.3404g silver nitrate, 0.4224g citric acid and 20mL deionized water evenly to obtain a mixed solution;

[0052] 2. Slowly add ammonia water dropwise while stirring in the above mixed solution, and adjust the pH value of the mixed solution to 8-9 to obtain a sol;

[0053] 3. Add 1.7978g of metatitanic acid to the above sol, ultrasonically disperse it for 10-15min, then stir it magnetically for 20-30min, then heat it in a water bath at 80-90°C, and put it in a blast drying oven after the system loses its fluidity Dry at 120°C for 12 hours to obtain the precursor;

[0054] 4. Put the above precursor into a tube furnace, under the protection condition of nitrogen flow, first raise the temperature to 300°C at a rate of 6°C / min, keep it warm for 10 minutes, and then raise the temperature to 400°C at a rate of 2°C / min ℃, hold for 120min, and finally cool down with the furnace to obtain Ag 2 S / TiO 2 composite photocatalyst.

Embodiment 2

[0056] 1. Mix 0.3404g silver nitrate, 0.5069g citric acid and 20mL deionized water evenly to obtain a mixed solution;

[0057] 2. Slowly add ammonia water dropwise while stirring in the above mixed solution, and adjust the pH value of the mixed solution to 8-9 to obtain a sol;

[0058] 3. Add 1.7978g of metatitanic acid to the above sol, ultrasonically disperse it for 10-15min, then stir it magnetically for 20-30min, then heat it in a water bath at 80-90°C, and put it in a blast drying oven after the system loses its fluidity Dry at 120°C for 12 hours to obtain the precursor;

[0059] 4. Put the above precursor into a tube furnace, under the protection condition of nitrogen flow, first raise the temperature to 300°C at a rate of 6°C / min, keep it warm for 10 minutes, and then raise the temperature to 400°C at a rate of 2°C / min ℃, hold for 120min, and finally cool down with the furnace to obtain Ag 2 S / TiO 2 composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com