Seedling cultivation pipeline assembly for seedling automated circulation and manual fixed point operation and using method thereof

An assembly line and artificial technology, applied in the field of plant cultivation, can solve the problems of long walking distance, need for protection, high labor intensity and other problems of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

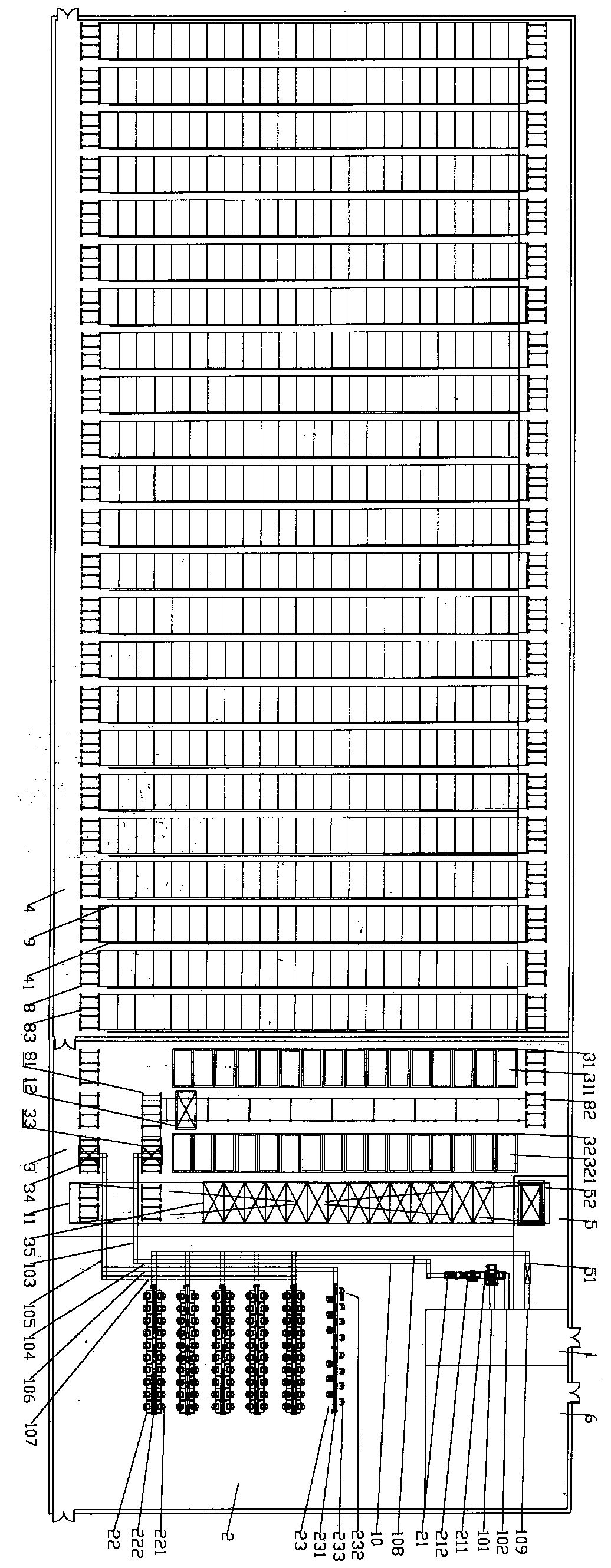

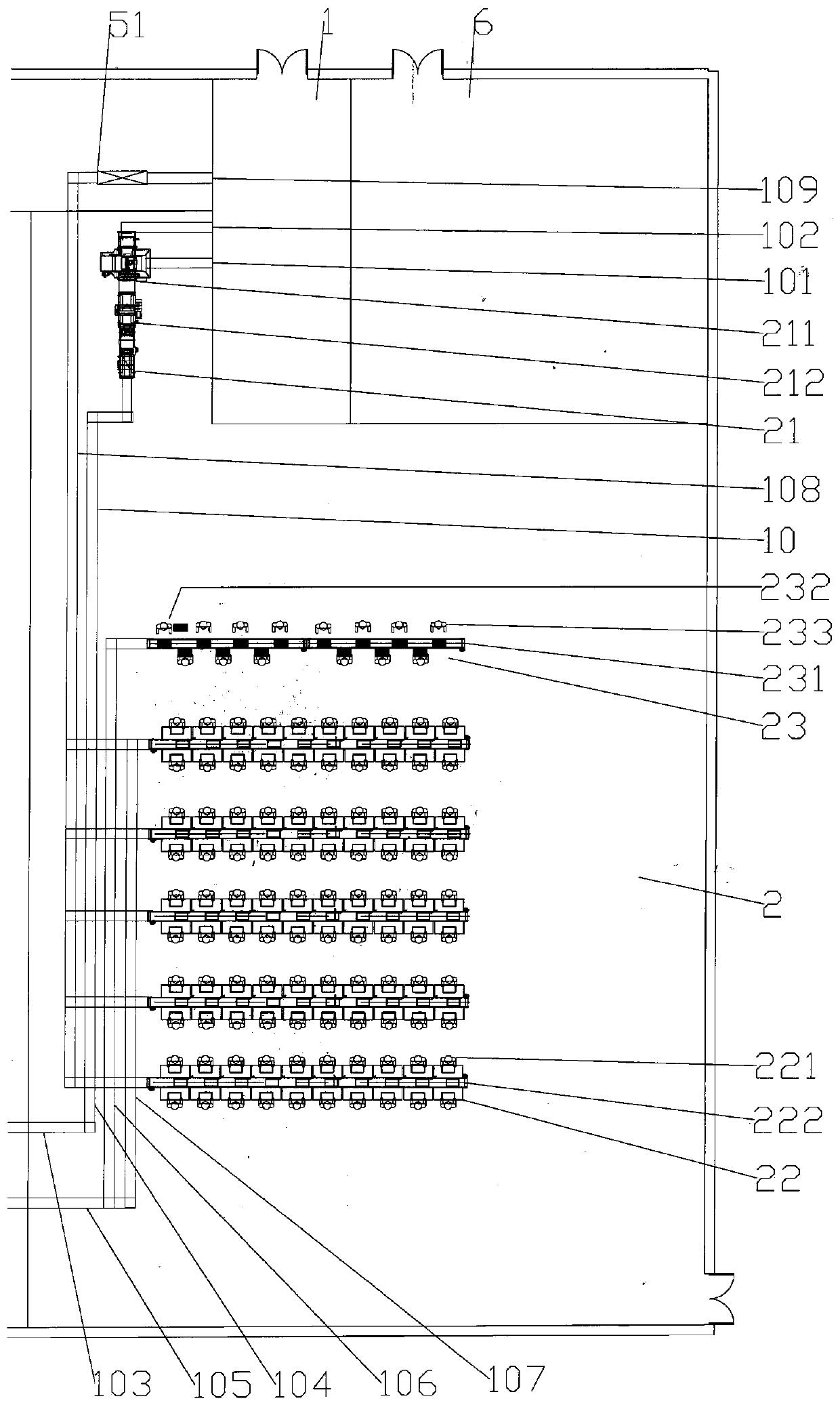

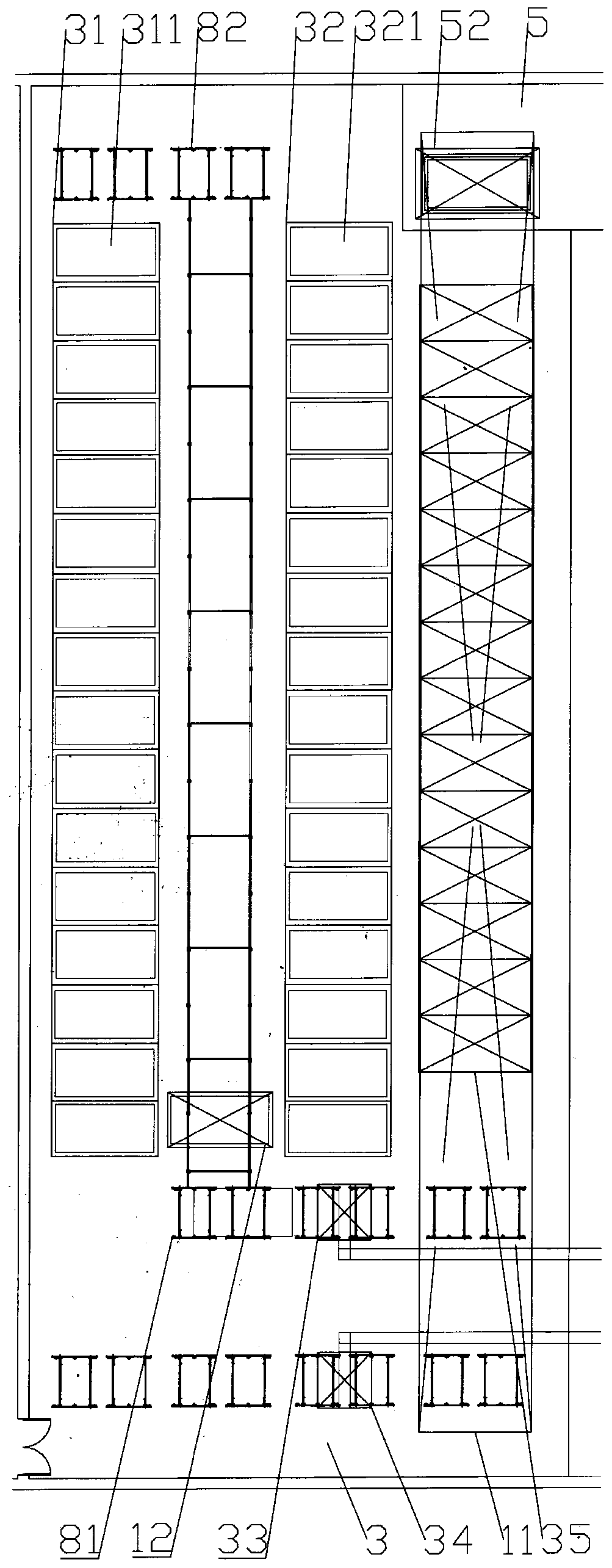

[0070] The seedling raising assembly line combination of automatic seedling circulation and manual fixed-point operation of the present invention, the overall and partial structural schematic diagrams are shown in figure 1 , figure 2 , image 3 , Figure 4 , which is:

[0071] The factory area is divided into areas with different temperature and humidity environments: material storage area 1, crop processing area 2, crop growth promotion area 3 with a germination area 31 and a healing area 32, crop growth area 4, cleaning area 5, and finished product storage area 6;

[0072] Seedbeds and / or plug trays are used as the basic logistics unit, and wheeled tracks 8, push-pull tracks 9, conveyor belts 10, light-load cranes 11, and mobile elevators 12 are used to form an assembly line for seedlings to flow in the above-mentioned areas. The specific settings are as follows :

[0073] The material storage area 1 is stocked with trays and substrates;

[0074] The crop processing a...

Embodiment 2

[0093] Using the pipeline of Embodiment 1, the control environment of each area is as follows:

[0094] Material storage area 1: temperature 15-30 degrees Celsius, relative humidity 20%-80%; no strict control is required;

[0095] Crop processing area 2: The temperature in summer and autumn is 23-28 degrees Celsius, the relative humidity is 30%-60%, the temperature in winter and spring is 20-25 degrees Celsius, and the relative humidity is 40%-70%. Strict control is required to be suitable for laborers and automation equipment;

[0096] Crop growth promotion zone 3: germination zone 31 temperature 28-32 degrees Celsius, relative humidity higher than 85%, healing zone 32 temperature 22-28 degrees Celsius, relative humidity higher than 90%; strict control is required to suit a particular crop growth stage;

[0097] Crop growth zone 4: daytime temperature 24-28 degrees Celsius, relative humidity 50%-70%, night temperature 16-20 degrees Celsius, relative humidity 50%-70%; strict ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com