Packaging machine capable of rapidly switching specifications

A technology for fast switching and packaging machines, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of time-consuming adjustment, poor accuracy, and inconvenient adjustment, and achieve shortened travel distance, low processing and assembly accuracy requirements, and saving The effect of rise and fall times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

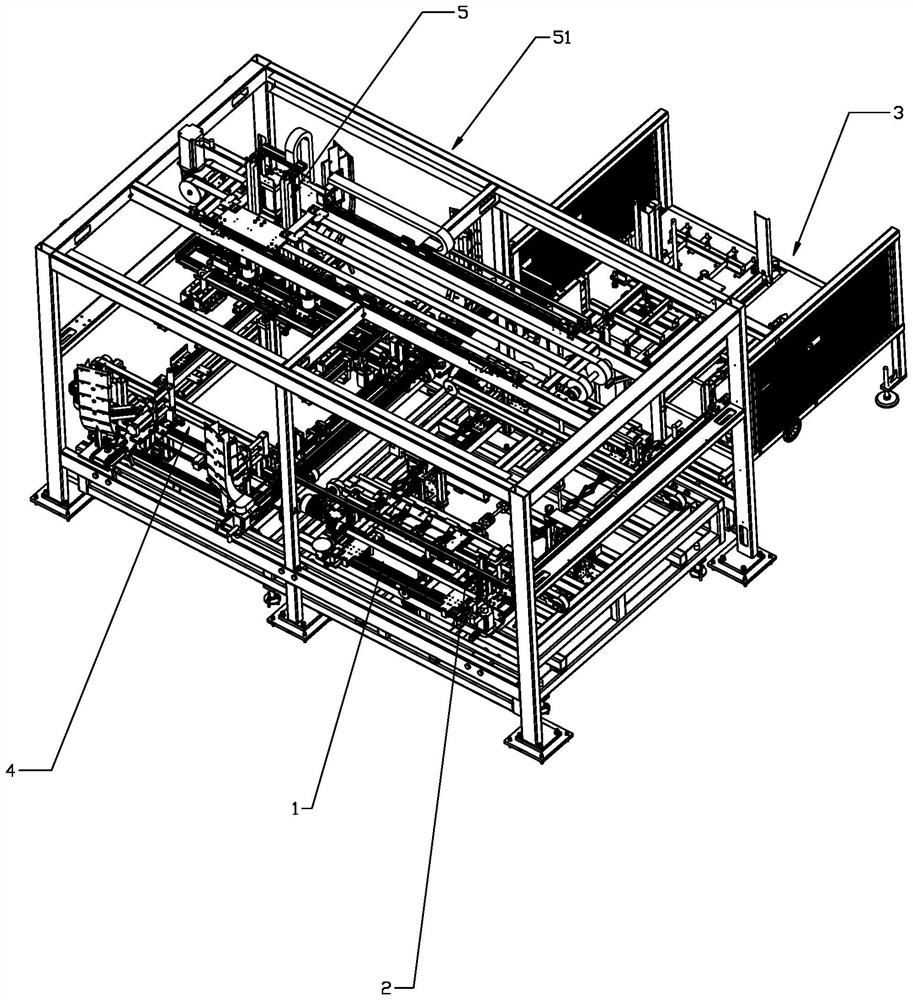

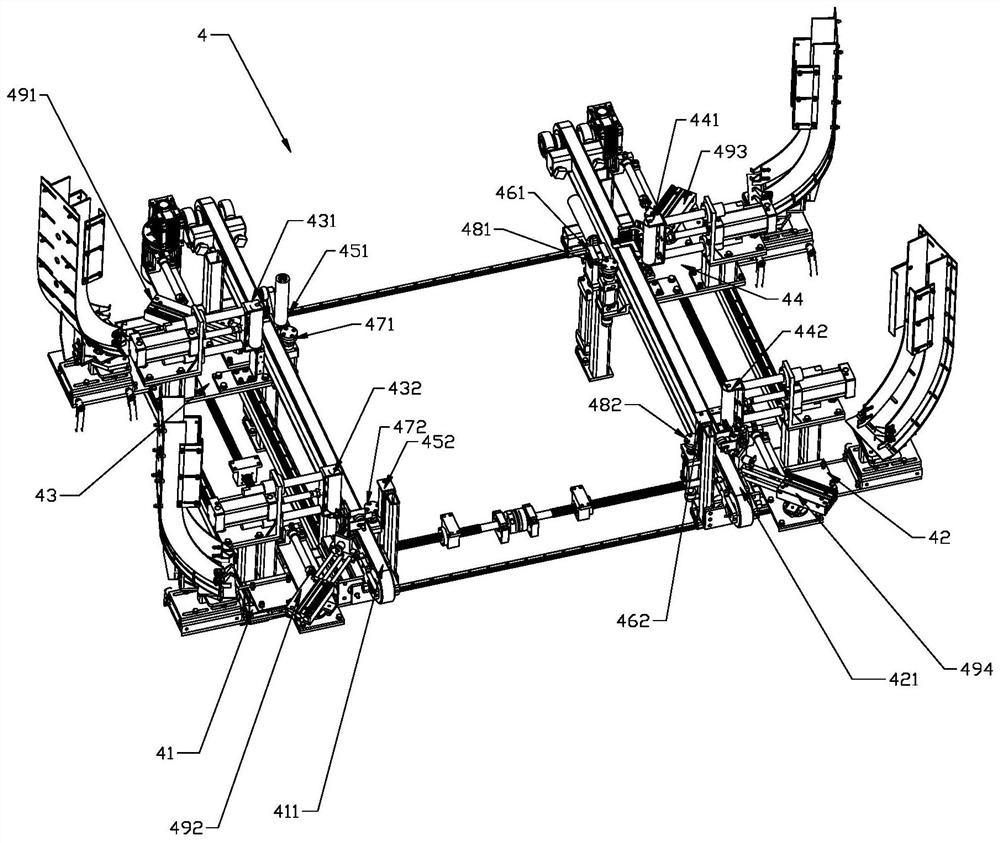

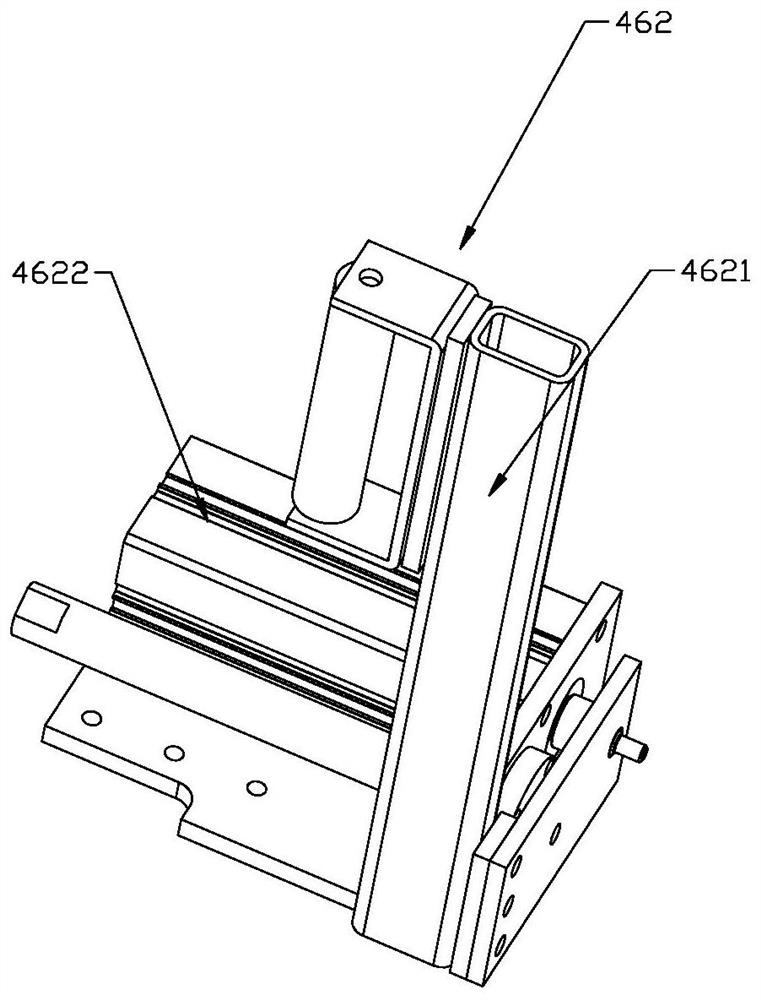

[0052] Such as figure 1 , 2 , 6, 12, 21, and 25, a packaging machine for quickly switching specifications, including a shaping and setting device 1, a brick holding device 2, a forming device 3, a paper bin device 4 and a paper feeding device 5, the The shaping and angle setting device is arranged on the front half of the packaging machine frame, and the shaping and angle setting device 4 includes a corner-taking mobile frame, a brick feeding mechanism arranged on the corner-taking mobile frame, left and right clapping components, front and rear clapping All components; the brick-holding angle device is installed above the shaping and angle-setting device through the brick-moving frame 51, and the brick-holding angle device includes a brick-holding angle lifting mechanism arranged on the brick-moving frame 51, The translation mechanism 53 arranged on the brick-moving frame 51, the brick-holding clamp mechanism 54 provided below the brick-holding angle lifting mechanism 52, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com