A pogo pin test connector suitable for semiconductor wafer fabrication

A technology for testing connectors and pogo pins, which is applied in semiconductor/solid-state device testing/measurement, instruments, measuring devices, etc., and can solve problems such as misalignment and affecting test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] as attached figure 1 to attach Figure 8 Shown:

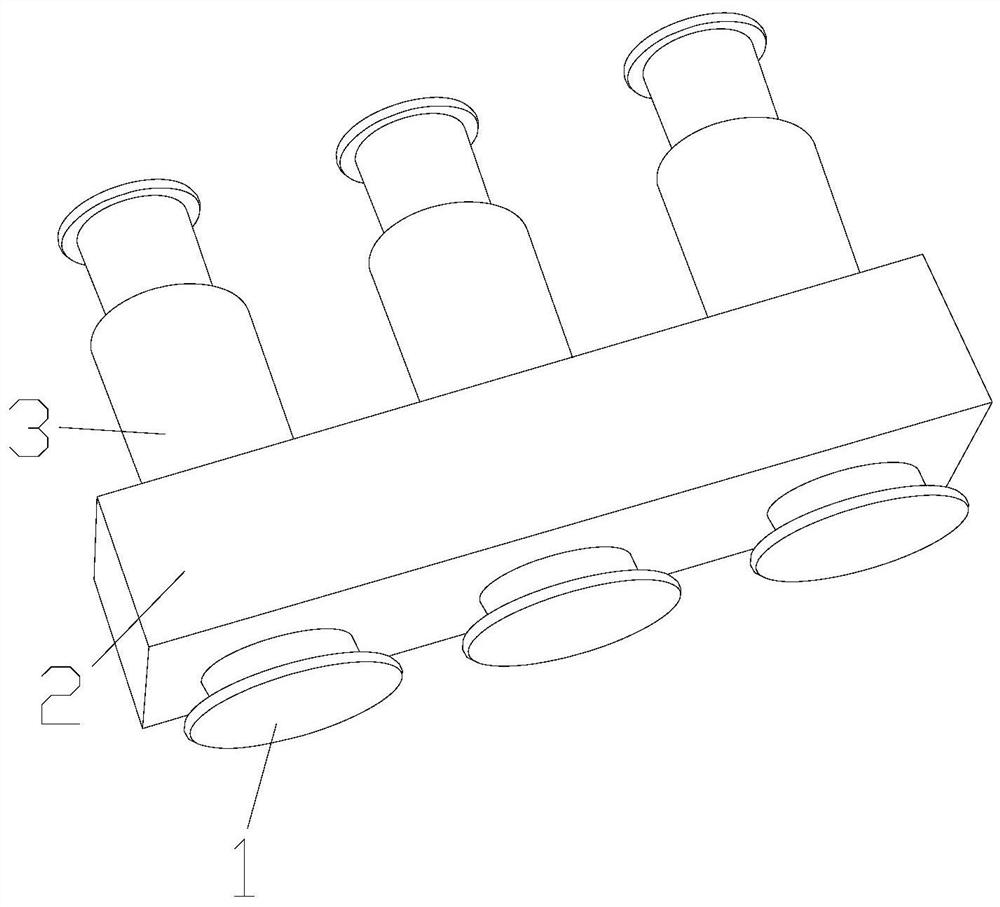

[0031] The invention provides a pogo pin test connector suitable for manufacturing semiconductor wafers, the structure of which includes a spring top 1 , a connector 2 and an anti-slip pogo pin 3 .

[0032] The spring top 1 and the anti-slip pogo pin 3 are an integrated structure, the anti-slip pogo pin 3 penetrates inside the connector 2 , and the spring top 1 is embedded in the inside of the connector 2 .

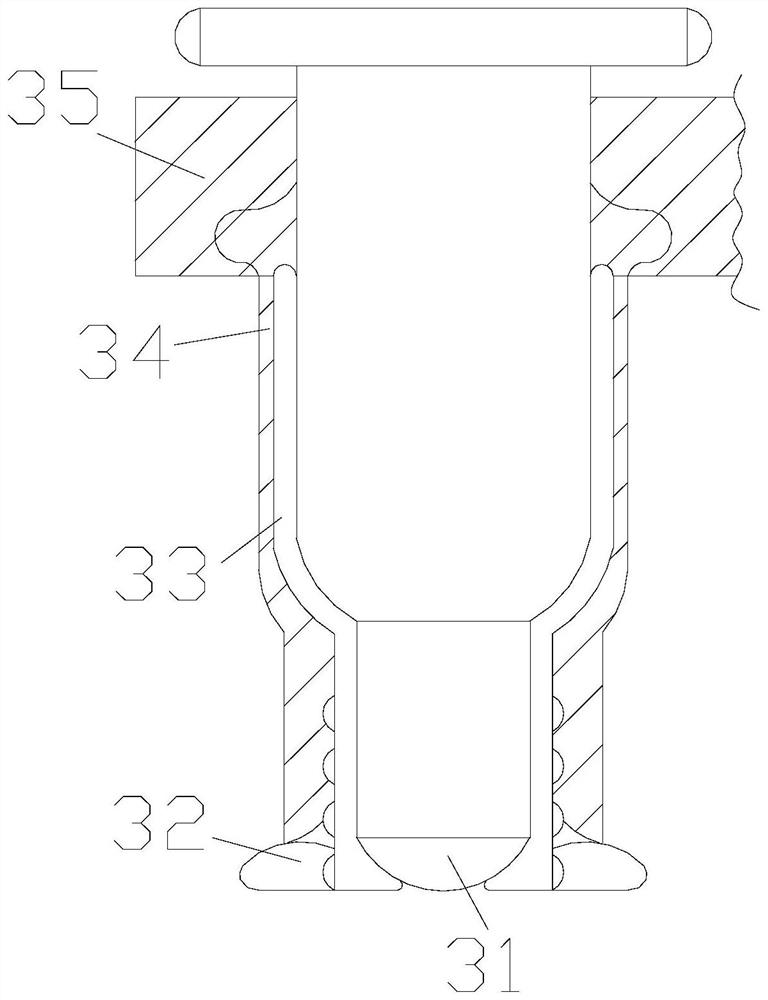

[0033] The anti-slip pogo pin 3 includes a test round head 31, a suction disc 32, an inner suction strip 33, a card layer 34, and an interlayer 35. The test round head 31 is located between the adsorption discs 32, and the inner suction strip 33 is installed on the Between the card layer 34 and the test round head 31 , the card layer 34 is embedded in the interlayer 35 , and the test round head 31 is arranged between the interlayer 35 .

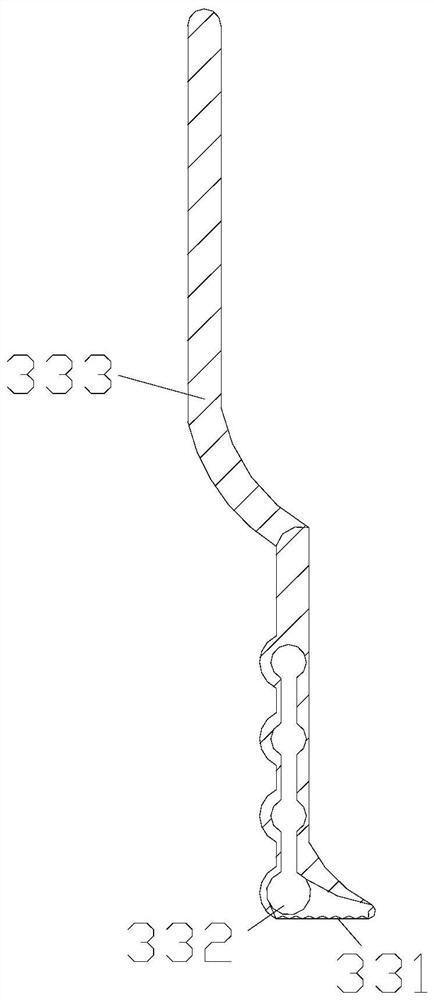

[0034] Wherein, the internal suction strip 33 includes a main water-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com