White smoke prevention intelligent detection method for wet desulphurization chimney

A detection method and wet desulfurization technology, which is applied in the field of automatic control of ultra-low emissions of coal-fired thermal power generating units, can solve the problems of high temperature waste of heat energy, blind recovery of heat energy, and no basis, so as to save coal consumption, be easy to implement, and accommodate easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

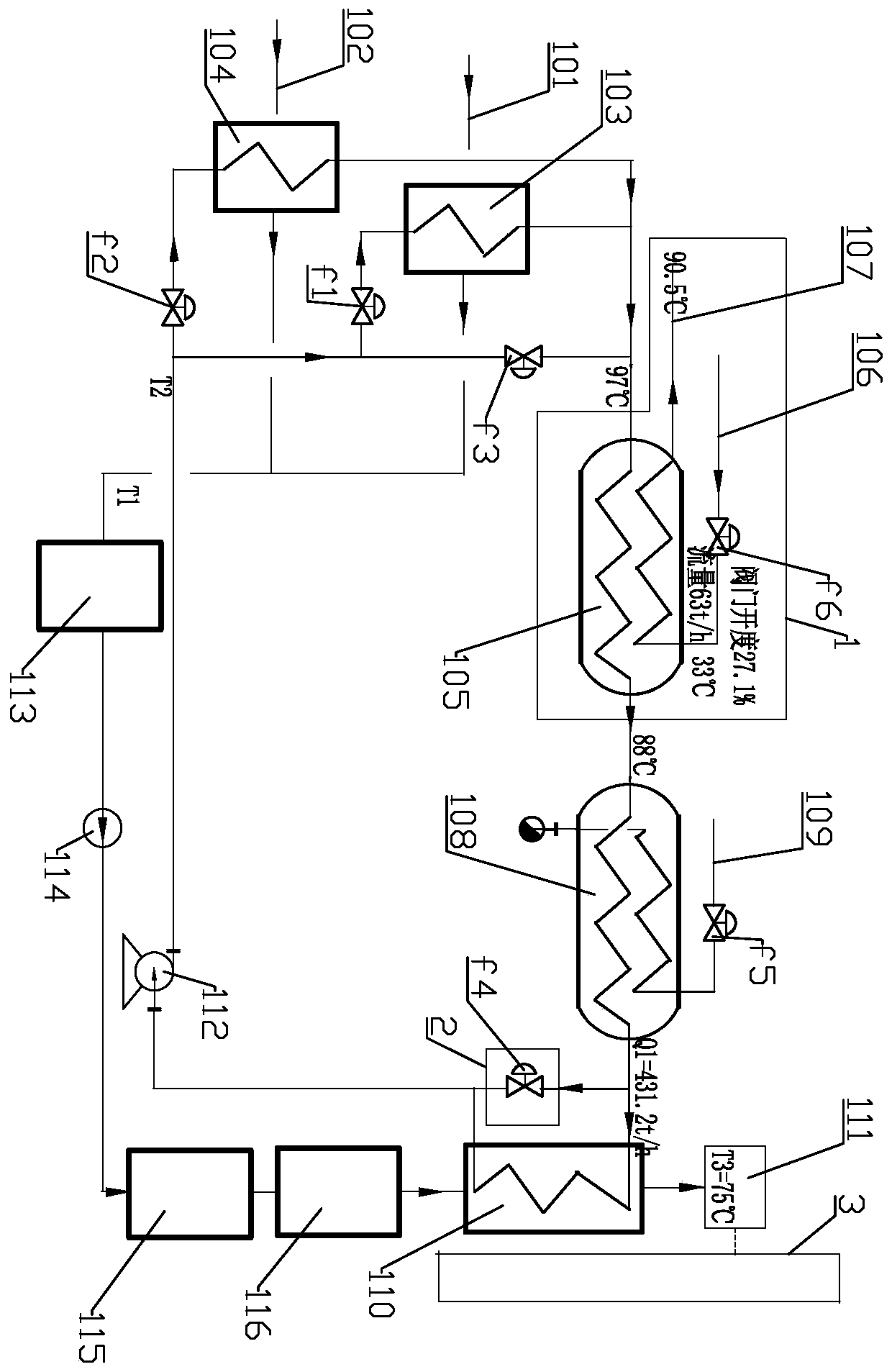

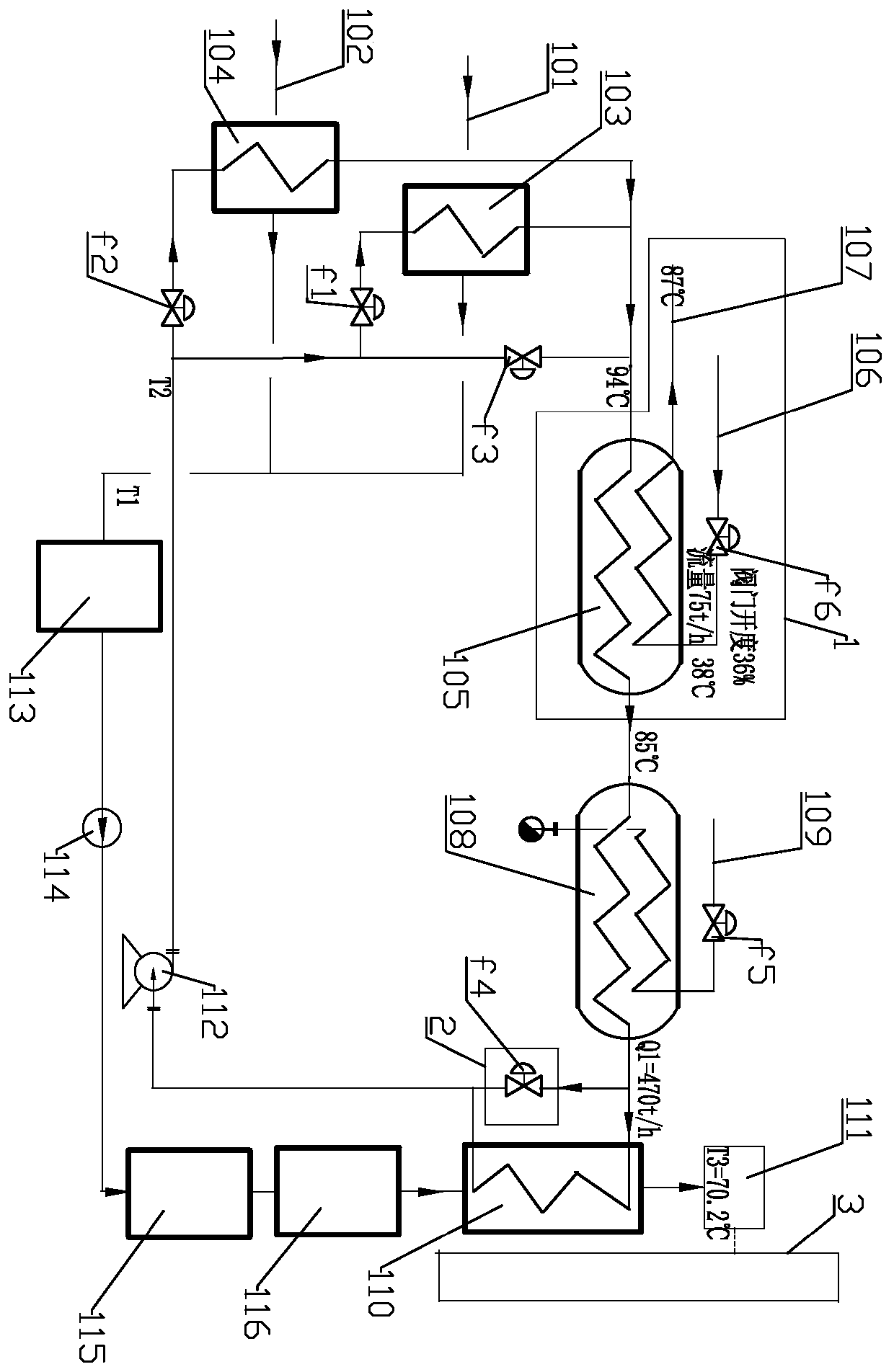

[0062] An intelligent detection method for white smoke prevention in wet desulfurization chimneys. This method determines the relationship between atmospheric temperature, atmospheric relative humidity, atmospheric wind force, wind direction and critical smoke temperature of chimney white smoke through experiments and statistical data analysis, so as to find the correlation formula, and import the formula into the control system; use the atmospheric temperature, atmospheric relative humidity, atmospheric wind force and wind direction signal as variables, introduce the correlation formula and automatically calculate the current "chimney white smoke critical smoke temperature" in real time; set the "chimney white smoke "Critical smoke temperature" is assigned to the chimney smoke temperature target set value, so as to automatically adjust the recovery capacity of the waste heat recovery system according to the critical smoke temperature of the chimney white smoke; the specific ste...

Embodiment 2

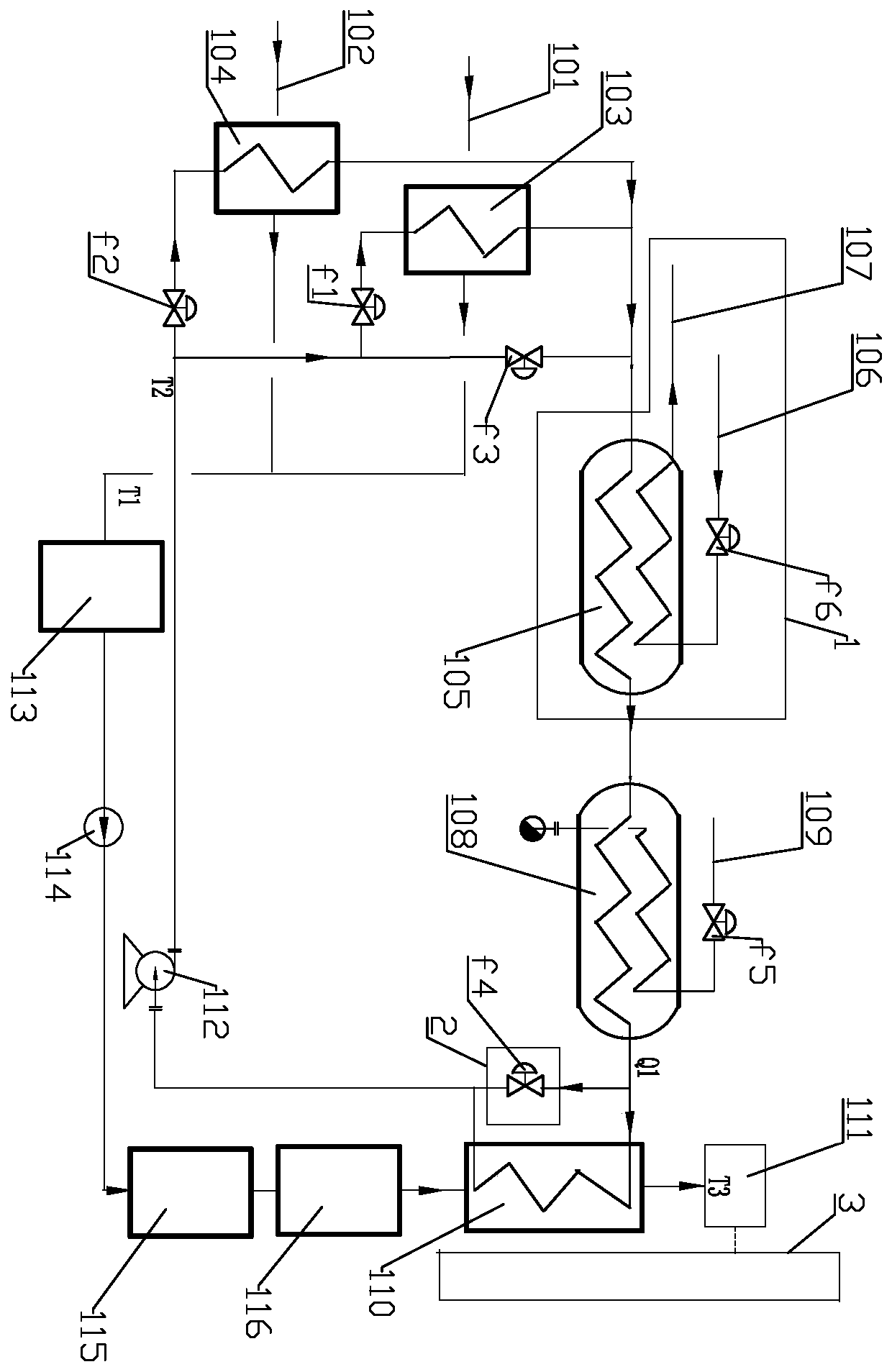

[0095] like figure 1 As shown, the first equipment 1 is added on the basis of the original design: that is, the water-to-water heat exchanger for the recovery of the waste heat of the flue gas of the tubular GGH flue gas, its pipeline and No. 6 regulating valve f6; the second equipment 2 is added on the basis of the original design : That is, the No. 4 regulating valve f4 (electric regulating valve) of the heat medium water inlet bypass of the tubular GGH flue gas heater; on the basis of the original design, a third device 3 is added: that is, the atmospheric temperature measuring point t around the chimney , Atmospheric relative humidity measuring point RH, atmospheric wind speed measuring point WS, atmospheric wind direction measuring point

[0096] "Increase the first equipment 1 on the basis of the original design" mentioned in the present invention means that a tubular GGH water-to-water heat exchanger is connected in parallel or in series on the original tubular GGH he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com