Electrode heating device manufactured from epoxy plate

An electrode heating and epoxy board technology, which is applied to thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of box cleaning and maintenance difficulties, and can prevent electric heating elements from burning, materials are easy, and no Effects of common failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

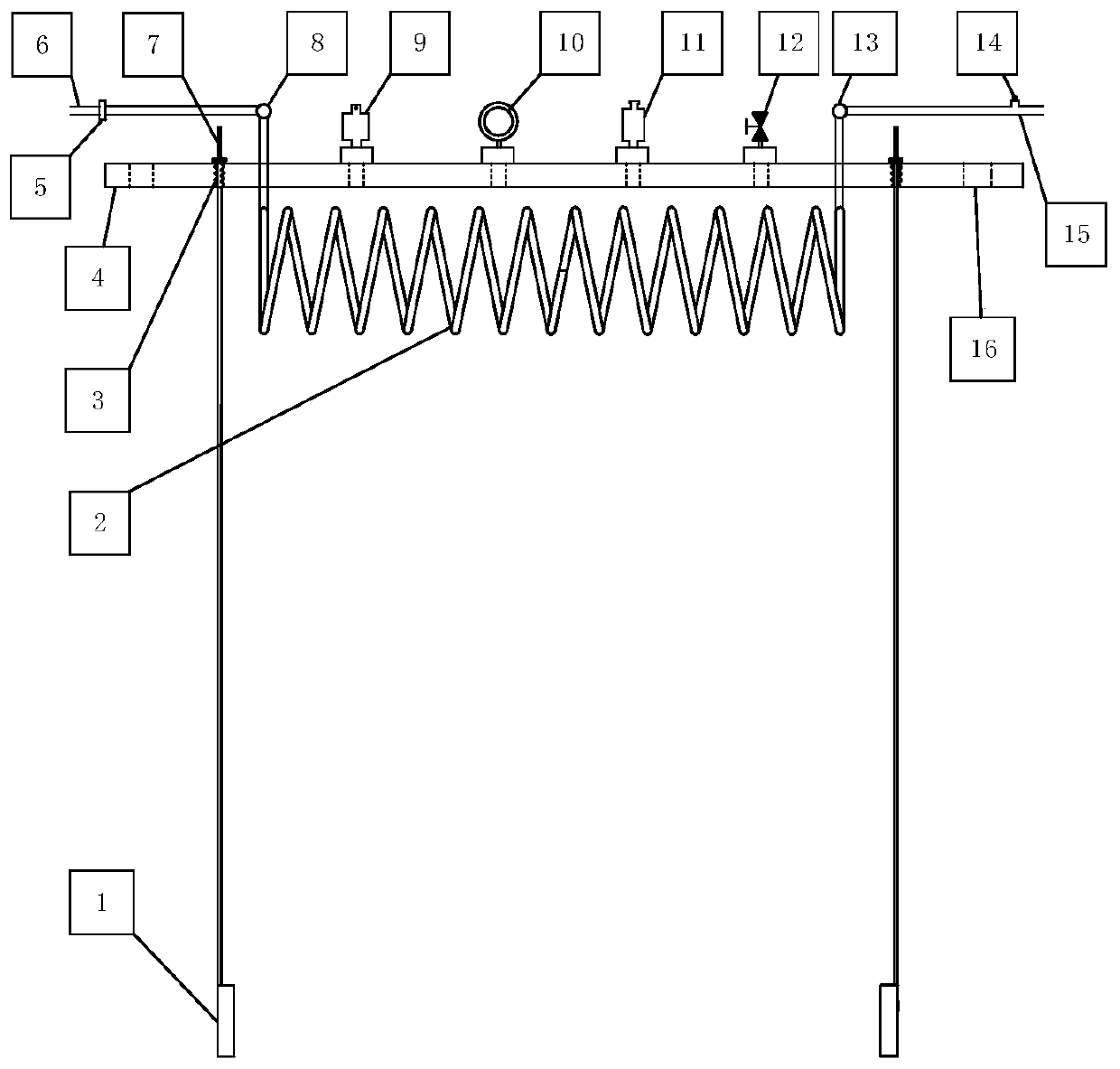

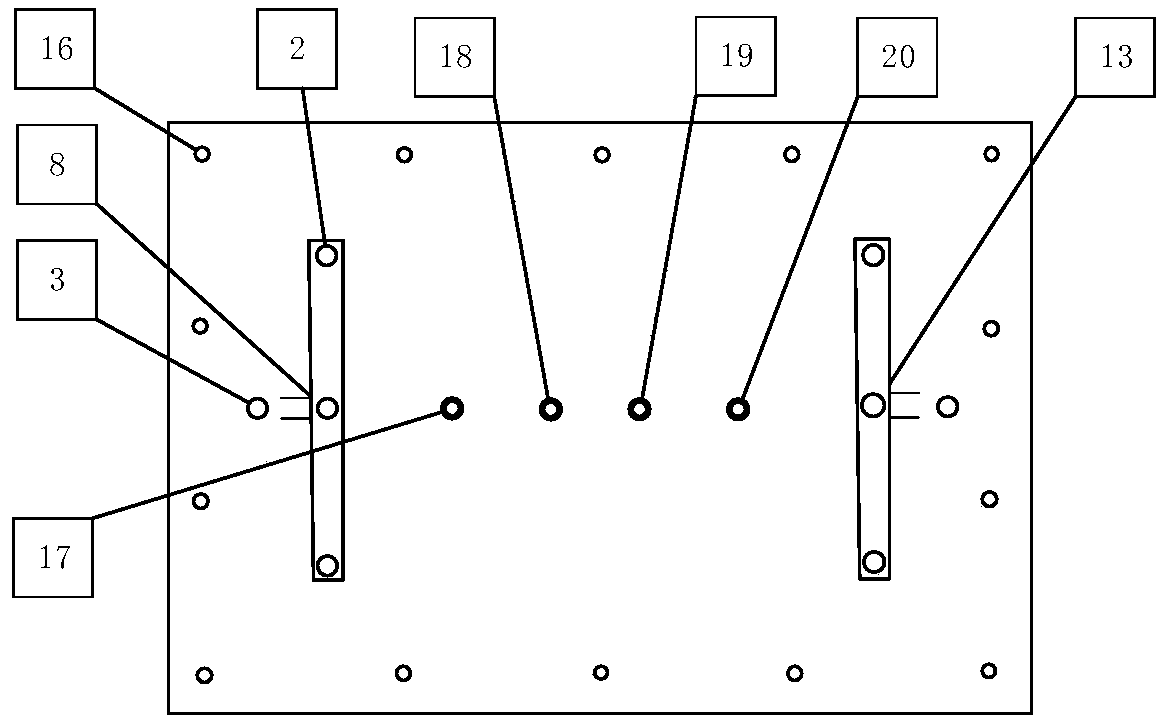

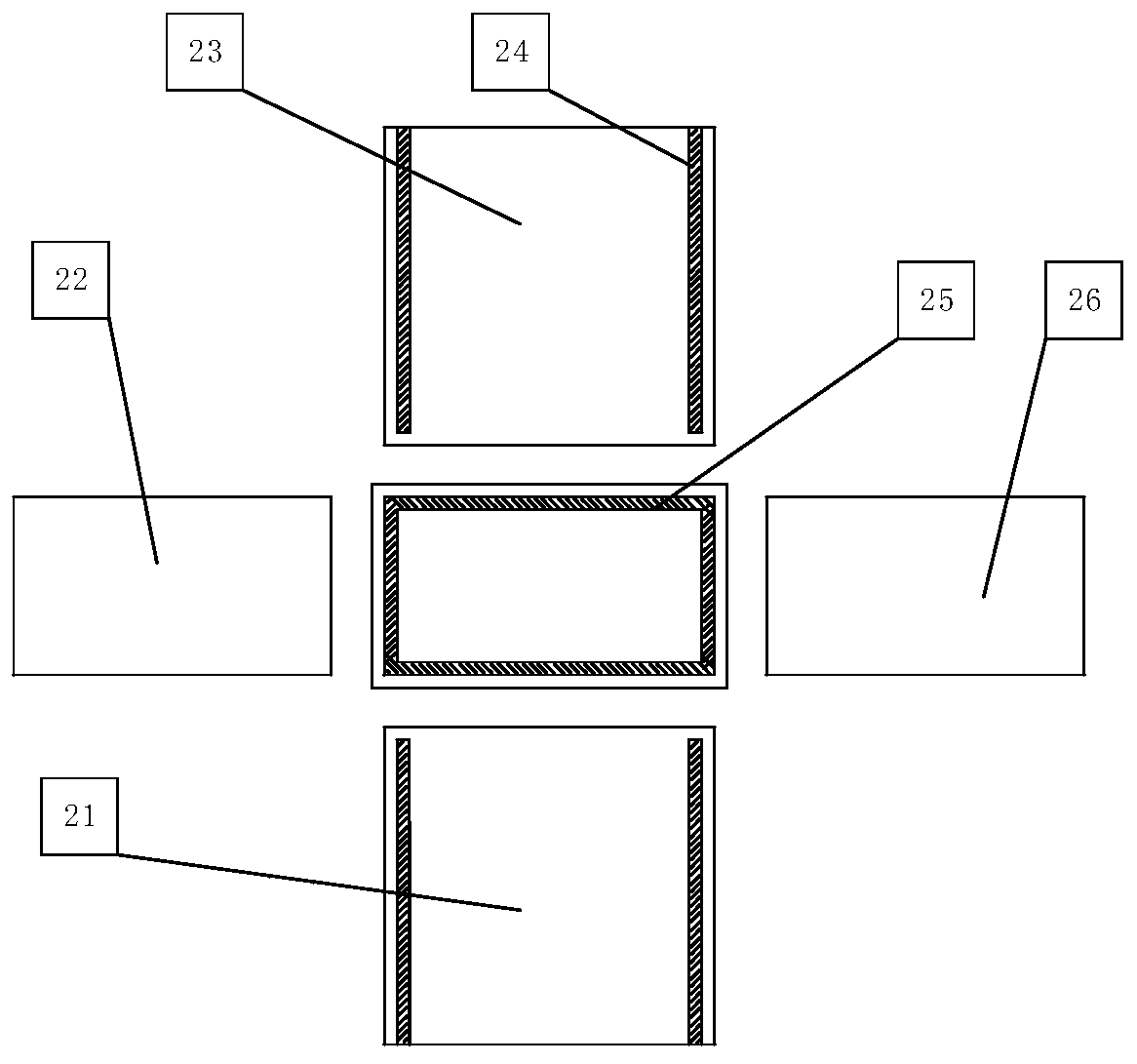

[0027] Such as Figure 5 As shown, the electrode heating device manufactured by epoxy board processing of the present invention mainly includes two parts, one is the electrode heating box Figure 4 , The second is the integrated cover figure 1 . The main implementation is as follows:

[0028] figure 1 It is a structural diagram of an integrated one-piece cover plate manufactured by epoxy board processing in the present invention. The electrode mounting nut 3, the vacuum valve mounting nut 17, the pressure gauge mounting nut 18, the pressure relief valve mounting nut 19, and the water injection device mounting nut 20 are bonded to the drilled mounting holes on the epoxy board 4 with high temperature resistant glue. In addition, the array of spiral heat exchange coils 2 are passed through the epoxy cover plate, and the contact point with the epoxy cover plate is glued together with high temperature resistant glue. The upper ends of the two ends of the heat exchange coil are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com