A pipeline and leak collection system with leak suppression and dredging functions

A collection system and pipeline technology, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., can solve problems such as medium transportation leakage, achieve good availability, simple structure, and shorten the effect of pre-cooling leakage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

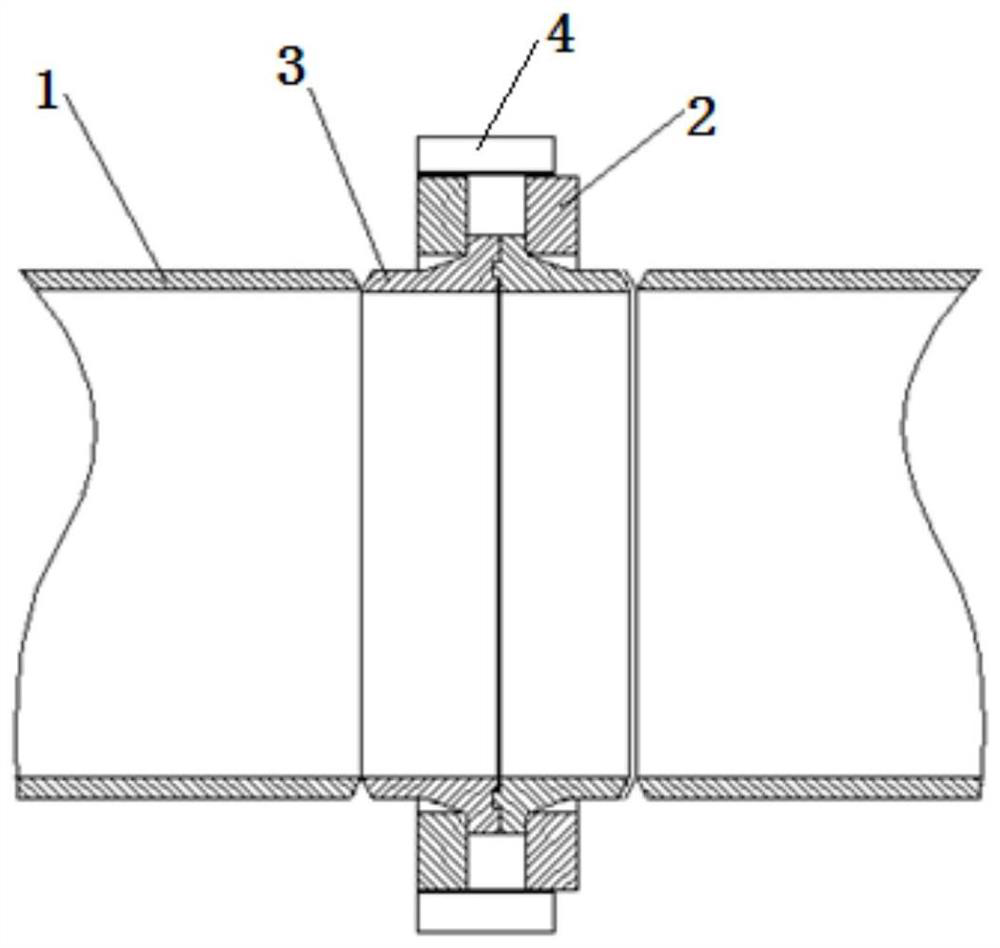

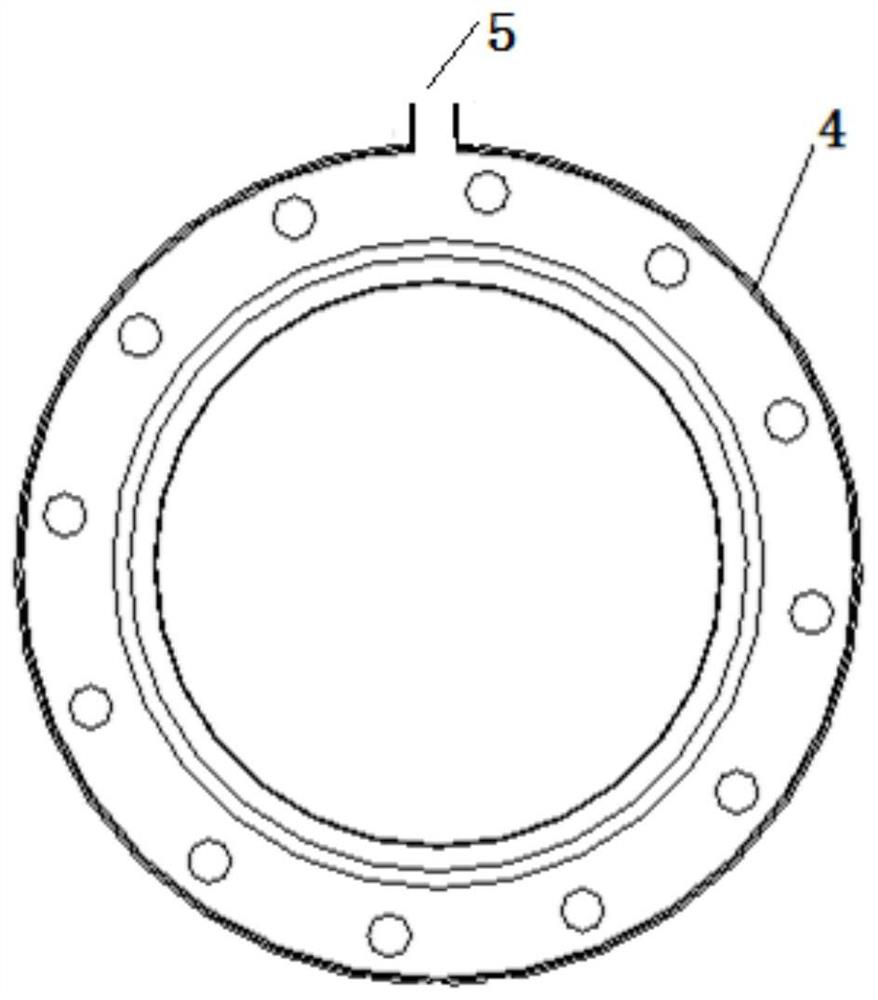

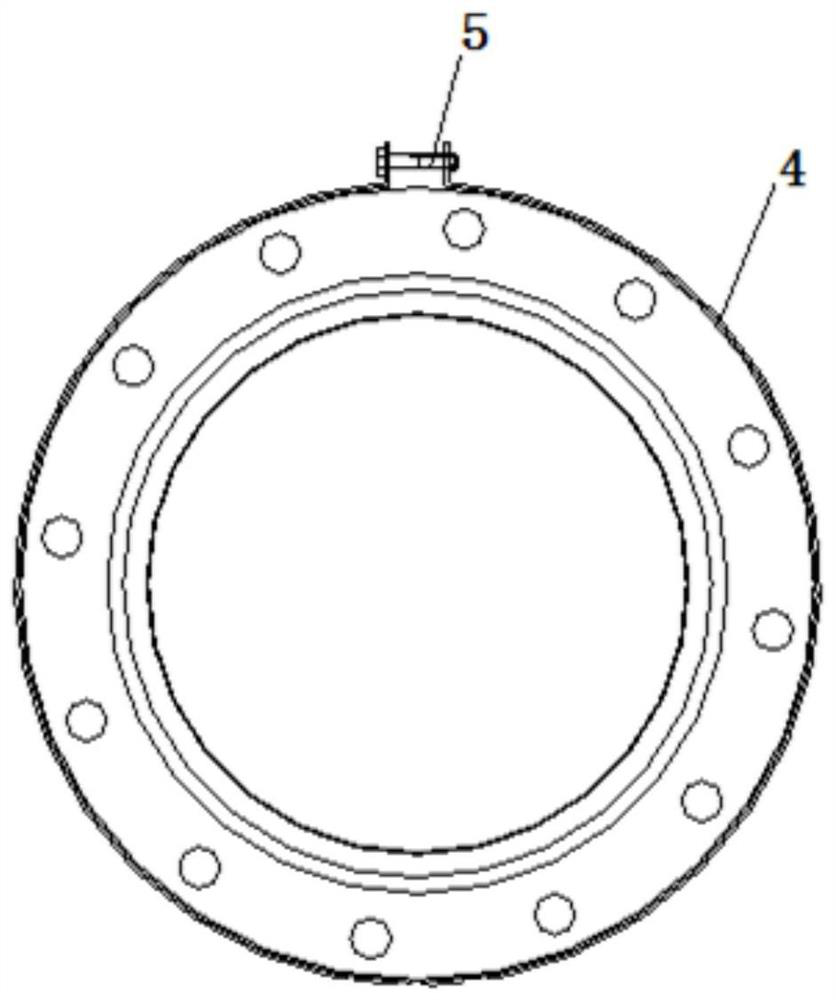

[0031] Such as figure 1 , a pipeline with leakage suppression and dredging functions, including a multi-section pipeline 1 with shoulder rings 3 at both ends, and two adjacent pipeline sections 1 are fixedly connected by two flanges 2 to compress the shoulder ring 3; A sealing ring 4 is set on the periphery of the flange 2, and a closed chamber is formed between the gap between the two flanges 2 and the sealing ring 4, and an exhaust port 5 communicating with the closed chamber is also provided on the sealing ring 4 .

[0032] The sealing ring is a full circle formed by two half-rings connected by bolts, or it can be formed by connecting multiple arc-shaped rings, or even a complete ring, as long as a closed chamber can be formed for the leakage medium to overflow. In addition, in some special occasions, if the pipe is square or heterogeneous, the solution of the present invention is also applicable, and it can be used only by adjusting the shape of the sealing ring to match ...

Embodiment 2

[0037] The present invention is also applicable to situations where drainage guidance or recovery of liquid media is required. Such as Figure 4 , a pipeline and leakage collection system with leak suppression and dredging functions, a multi-section pipeline 1 with shoulder rings 3 at both ends, two adjacent sections of pipeline 1 are fixed by two flanges 2 to compress the shoulder ring 3 connection; the periphery of the flange 2 is also provided with a sealing ring 4, and a closed chamber is formed between the gap between the two flanges 2 and the sealing ring 4, and the bottom of the sealing ring 4 is also provided with a drain port 7; The liquid discharge port 7 is connected with a liquid recovery device 8 through a pipeline.

[0038] Same as Example 1, the sealing structure is a full circle formed by two semi-circular rings connected by bolts, or it can be formed by connecting multiple arc-shaped rings, or even a complete circular ring, as long as a closed chamber can be ...

Embodiment 3

[0041] Such as Figure 5, for some low-temperature medium transportation leakage, when there are gas injection conditions at the use site, the effect of leakage suppression can be promoted by injecting gas into the closed chamber of Example 1. Two gas injection ports 6 are set in the lower part of the sealed structure, and air or nitrogen is selectively fed in according to the site conditions, and the principle of rapid gasification of low-temperature medium under the action of gas is used to take away the heat flow and homogenize the local uneven cooling parts . The number of gas injection ports can also be one or more, which can be changed according to the requirements of use. In this embodiment, two are used as an example to consider that if the number is too large, multiple gas sources need to be connected, which is inconvenient to operate. Or the design still needs to be set up according to the conditions and requirements of the site. The specific position of the gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com