Energy-dissipating damping device suitable for mortise-tenon joints of timber structures of ancient buildings

A shock-absorbing device and wood structure technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problem of large space occupation and achieve the effect of eliminating residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

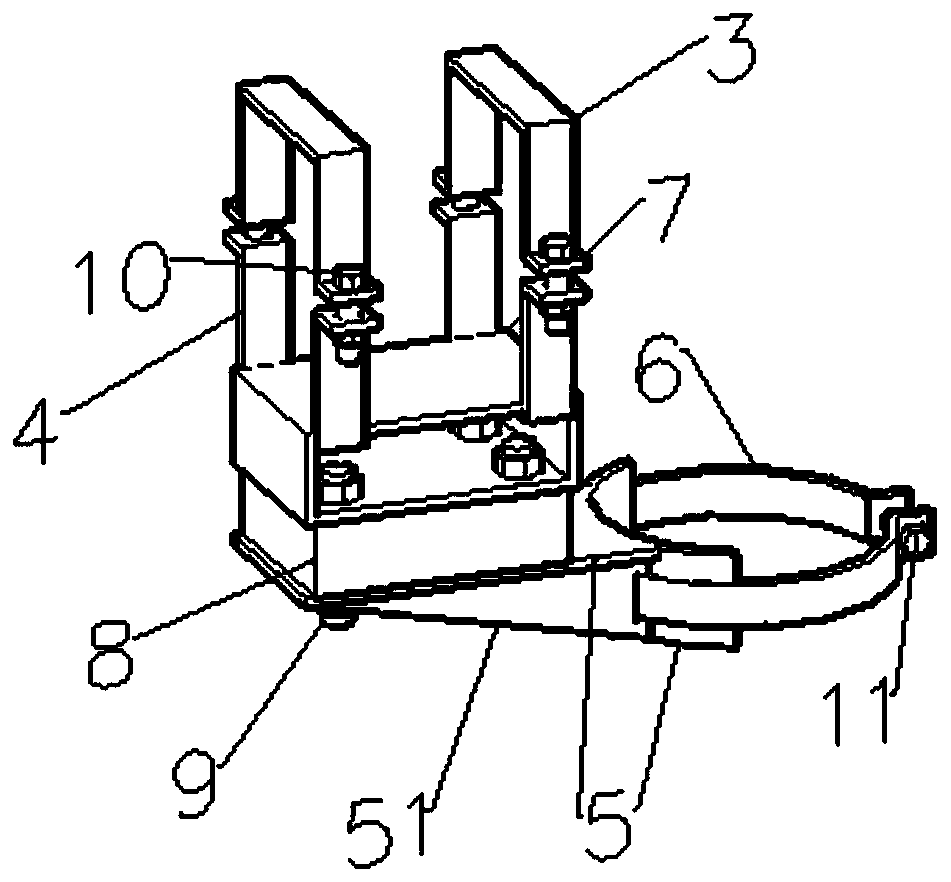

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes: connector I3, connector II4, steel bracket 5, connector III6, stiffener 51, rectangular steel pipe 7, viscous friction damper 8, metal energy dissipation rod 9, etc.

[0029] The connecting piece II4 is a rectangular frame with an upper opening, and the connecting piece I3 is a rectangular frame with a lower opening. Both openings have ear plates, and bolt holes are reserved on the ear plates. The connecting piece II4 passes through the rectangular frame located on the lower side of the wooden beam. The steel pipe 7 is connected with the connector I3 by the bolt I10 to form a closed rectangular frame, the inner cross-sectional size of the closed rectangular frame is consistent with the cross-sectional size of the wooden beam 1, and the wooden beam 1 is located in the closed rectangular frame to realize fixing. Wherein the rectangular steel pipe 7 reserves a certain gap betwe...

Embodiment 2

[0033] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the energy-dissipating and shock-absorbing devices of the present invention are installed on the upper and lower sides of the wooden beam; the connection method between the device and the structure is the same as that of Embodiment 1.

Embodiment 3

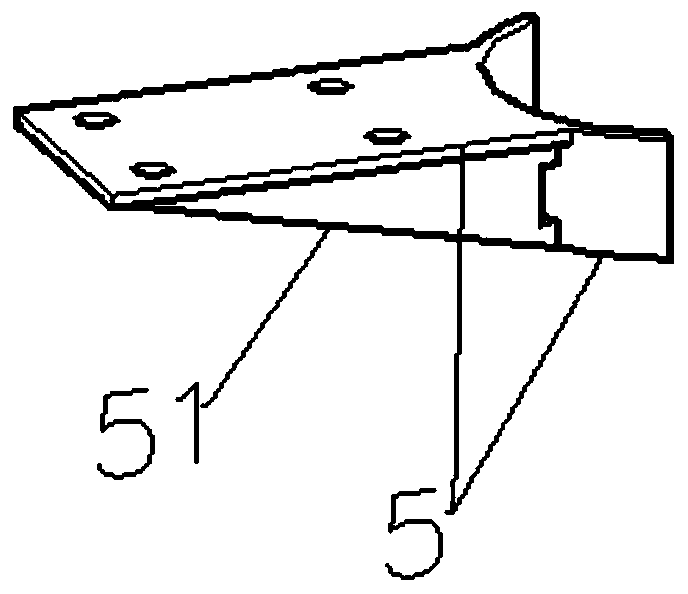

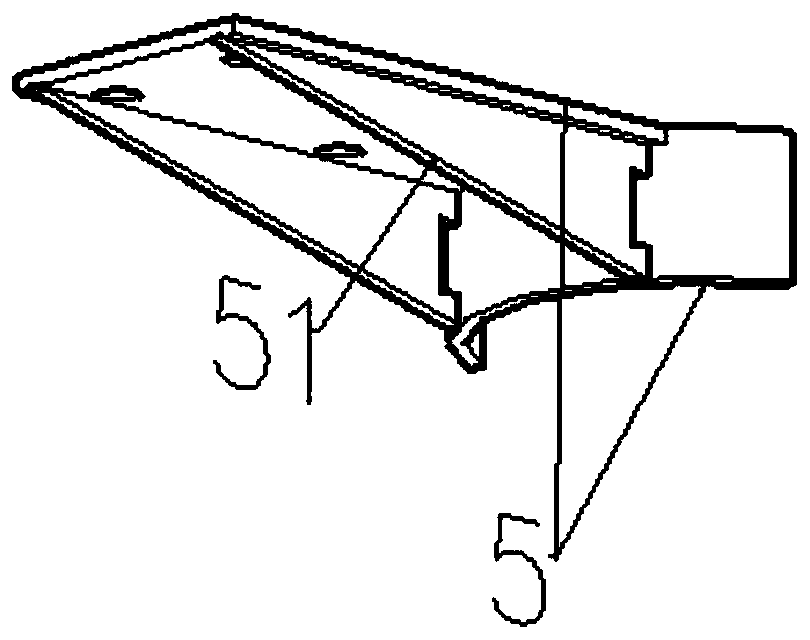

[0035] As preferred in embodiment 1, in the steel support 5, also comprise vertical steel plate, horizontal steel plate is connected on the outer surface of arc-shaped steel plate to be right angle shape, and the lower corner of horizontal steel plate is welded with stiffener 51, stiffener 51 and vertical There is a gap between the outer sides of the vertical steel plate and a part of the inner side of the connector III6, which is consistent with the size of the connector III6, and the connector III6 passes through the gap. combine.

[0036] When the connector III6 is circular, the vertical steel plate is an arc-shaped steel plate, and the surface attached to the wooden column 2 is arc-shaped with the same radius as the wooden column 2 .

[0037] When the present invention is applied in practice, the damping size of the nodes can be controlled by adjusting the thickness of the viscous friction damper 8, and different pretightening forces can be applied by adjusting the tightne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com