Cutting tool with a supporting body

A cutting tool and carrier technology, applied in the field of cutting tools, can solve problems such as uneven cutting and inability to provide, and achieve the effects of reducing tool cost, neat cutting, and improving spring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

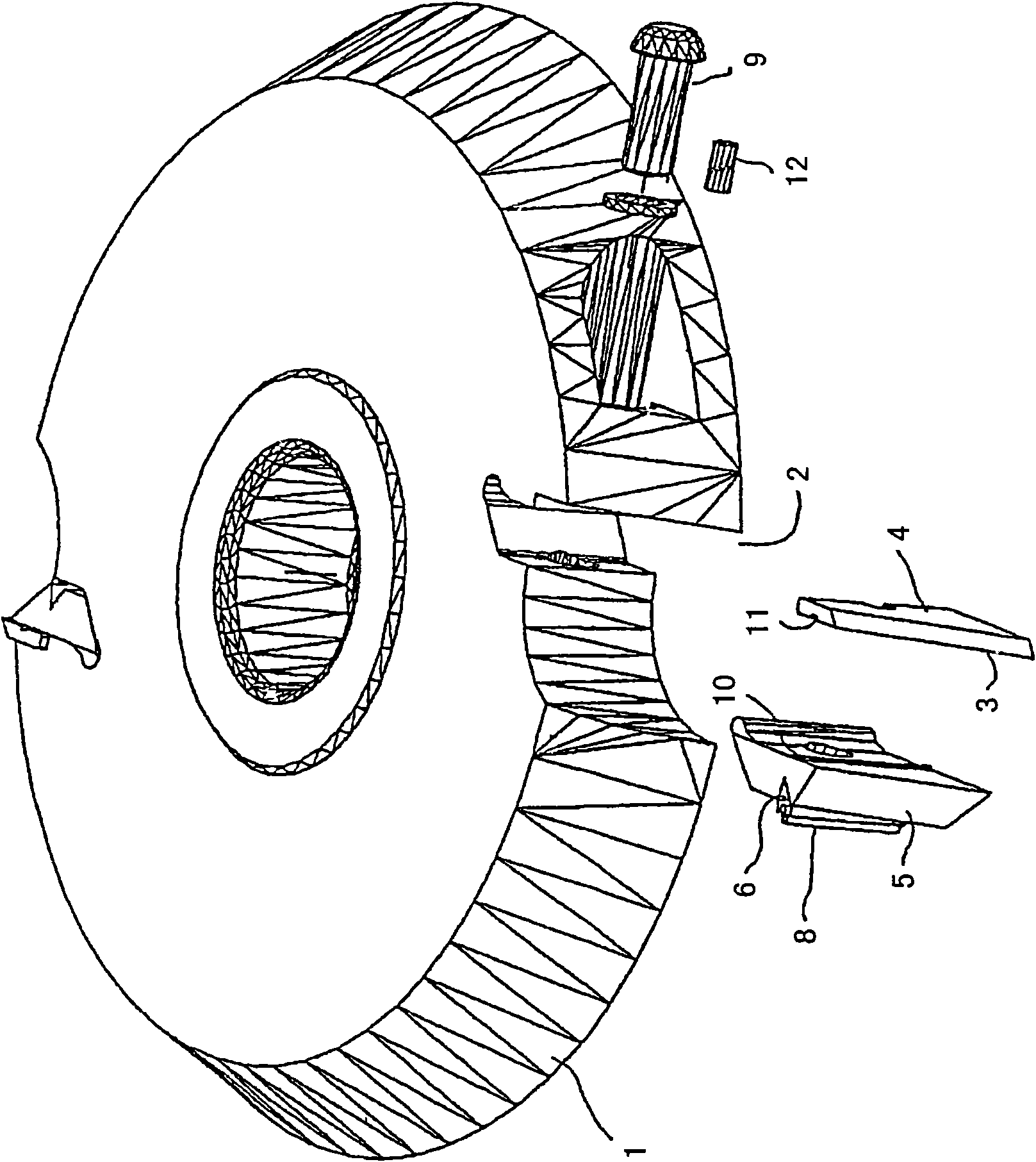

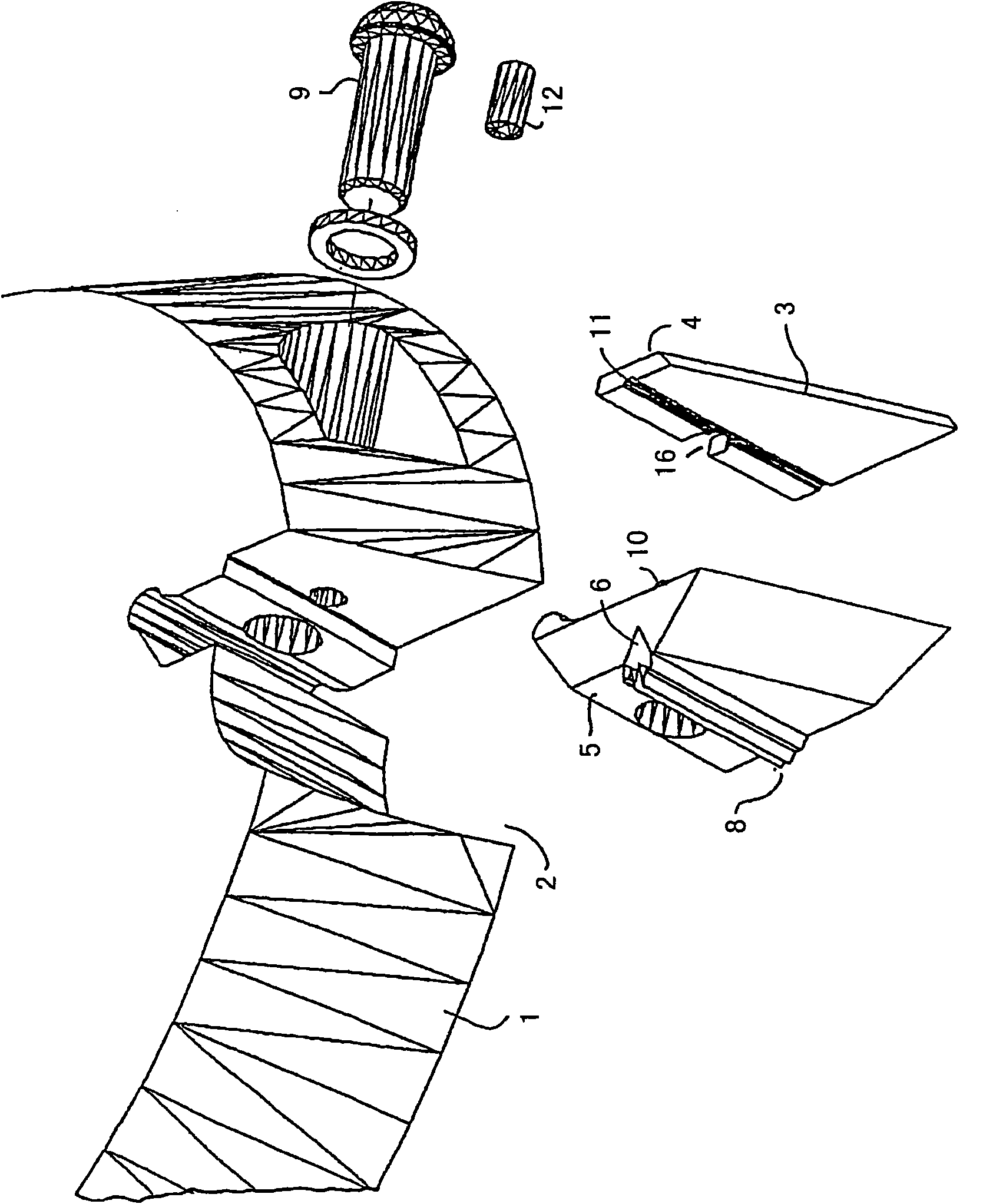

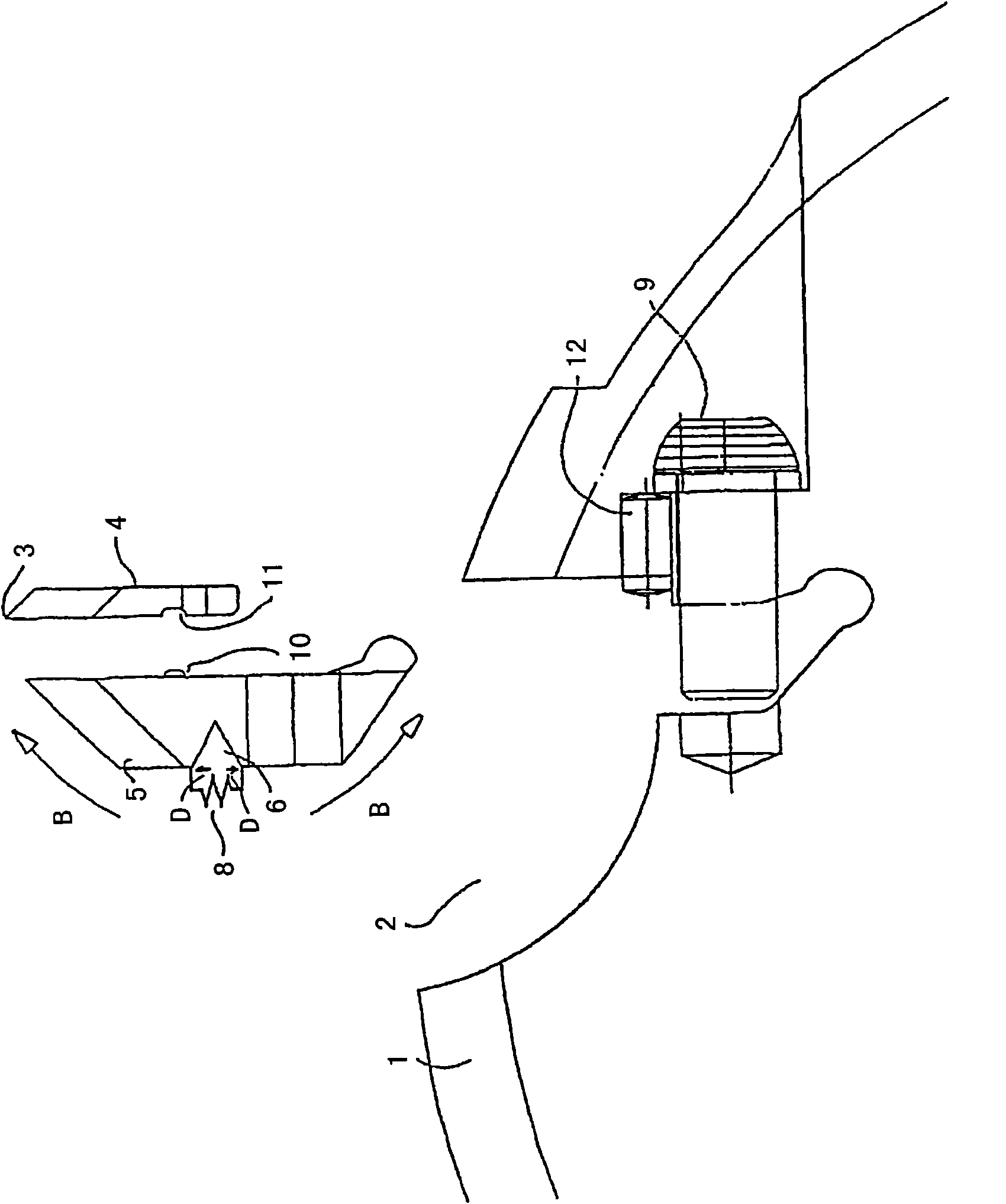

[0028] figure 1 A cutting tool is shown, which has a carrier body 1 and a receptacle 2 machined into the carrier body. The receptacle 2 can be formed either during the shaping process of the carrier body 1 or processed afterwards by milling, grinding or other processing methods. The receptacle 2 serves as a seat for a cutting element 4 whose cutting edge 3 extends radially outward from the carrier body 1 in the exemplary embodiment shown. In addition to the radially outwardly directed cutting edge 3 , the cutting edge 3 can extend radially inward, for example in the case of a whirl cutter.

[0029] The cutting element 4 is inserted into its seat, ie into the receptacle 2 , wherein a clamping jaw 5 is arranged opposite the seat, which clamps the cutting element 4 .

[0030] The clamping takes place by means of a screw 9 which engages through a through hole in the carrier body 1 into a thread formed in the clamping jaw 5 and clamps the cutting element 4 after applying a fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com