A nano with high specific heat capacity 3 Phase change heat storage material and preparation method thereof

A technology of heat storage material and high specific heat capacity, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of low specific heat capacity, high cost of nanoparticle synthesis, and inability to be applied in a large number of industrial applications, and achieves simple and cost-effective methods. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

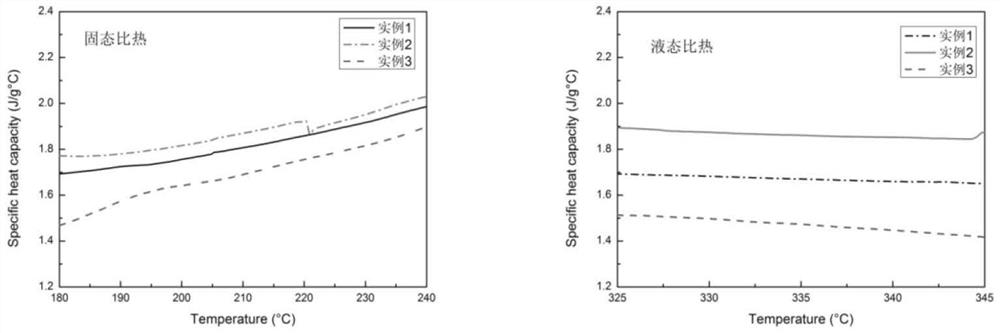

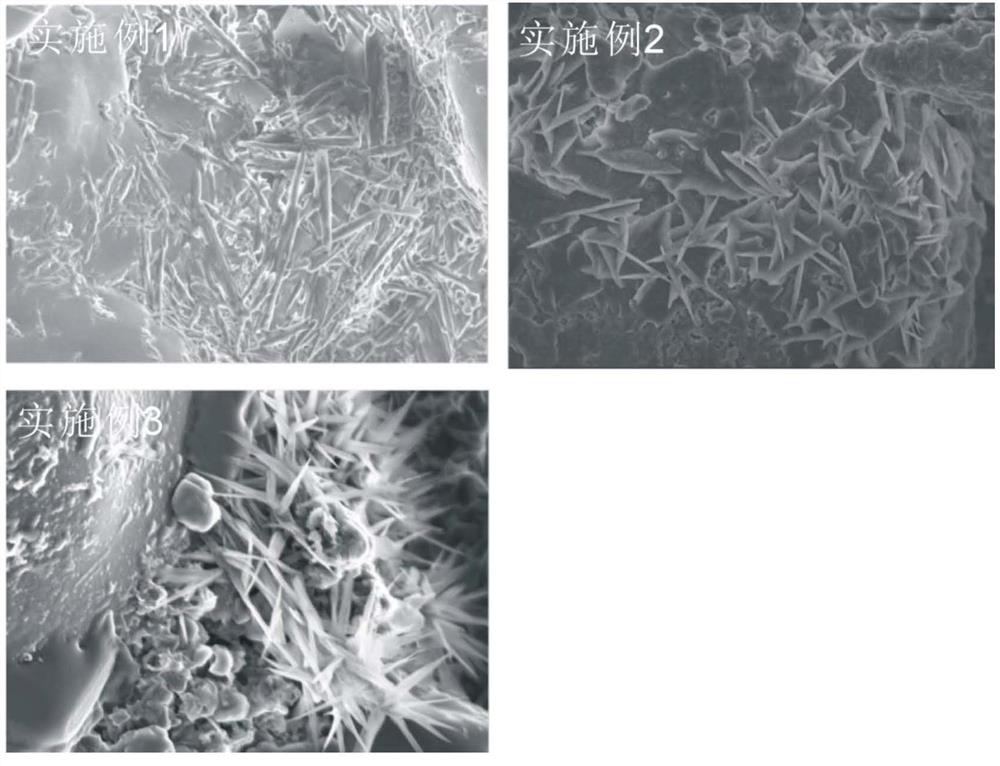

Embodiment 1

[0023] A kind of NaNO with high specific heat capacity 3 The heat storage material, the preparation method thereof specifically comprises the following steps:

[0024] (1) Pretreatment: Weigh 4.25g NaNO 3 and 1.5g urea, grind it for 10min to make it fully mixed, put it into the test tube; add 15ml deionized water to the test tube, fully dissolve; put the test tube into the water bath and heat it for 2h, the temperature of the water bath is 100°C, and ultrasonically oscillate for 30min, so that the solution Mix well, and the resulting mixed solution is put into a crucible and waits to be ignited;

[0025] (2) Combustion modification: Preheat the temperature of the well furnace to 500°C; put the crucible containing the mixed solution obtained in step (1) into the well furnace to ignite, and take out the sample in the crucible after igniting for 15 minutes, thereby obtaining Modified NaNO 3 The heat storage material is NaNO with high specific heat capacity 3 Heat storage mate...

Embodiment 2

[0028] A kind of NaNO with high specific heat capacity 3 The heat storage material, the preparation method thereof specifically comprises the following steps:

[0029] (1) Pretreatment: Weigh 4.25g NaNO 3 and 3g of urea, grind it for 10 minutes to make it fully mixed, put it into the test tube; add 15ml deionized water to the test tube, fully dissolve; put the test tube in a water bath and heat it for 2 hours, the temperature of the water bath is 100°C, and ultrasonically oscillate for 30 minutes to make the solution fully Mix, and the resulting mixed solution is put into a crucible and waits to be ignited;

[0030] (2) Combustion modification: Preheat the temperature of the well furnace to 500°C; put the crucible containing the mixed solution obtained in step (1) into the well furnace to ignite, and take out the sample in the crucible after igniting for 15 minutes, thereby obtaining Modified NaNO 3 The heat storage material is NaNO with high specific heat capacity 3 Heat ...

Embodiment 3

[0033] A kind of NaNO with high specific heat capacity 3 The heat storage material, the preparation method thereof specifically comprises the following steps:

[0034] (1) Pretreatment: Weigh 4.25g NaNO 3 and 6g of urea, grind it for 10 minutes to make it fully mixed, put it into the test tube; add 15ml deionized water to the test tube, fully dissolve; put the test tube in a water bath and heat it for 2 hours, the temperature of the water bath is 100°C, and ultrasonically oscillate for 30 minutes to make the solution fully Mix, and the resulting mixed solution is put into a crucible and waits to be ignited;

[0035] (2) Combustion modification: Preheat the well furnace temperature to 500°C; put the crucible containing the mixed solution obtained in step (1) into the well furnace and ignite it, and take out the sample in the crucible after igniting for 15 minutes to obtain Modified NaNO 3 The heat storage material is NaNO with high specific heat capacity 3 Heat storage mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com