High-torsion-resistance foaming material and preparation method and application thereof

A foam material and high-resistance technology, applied in applications, soles, clothing, etc., can solve problems that affect consumers' wearing comfort, increase production costs, and increase specific weight, so as to improve sports experience, prevent sprains or sprains, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

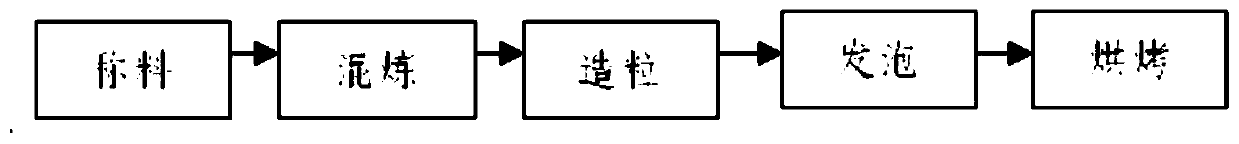

[0052] The embodiment of the present invention provides the preparation method of the high-torsion-resistant foam material as described above, including the following steps: sequentially kneading and granulating the EVA composite material, and then foaming to obtain a high-torsion-resistant foam Material.

[0053] The technological process of the embodiment of the present invention is as figure 1 As shown, it mainly includes: weighing→mixing→granulation→foaming→baking. The embodiment of the present invention is grouped and weighed first: according to the dosage of the formula, the plastic main materials such as EVA / EPDM / OBC / special polyolefin elastomer can be weighed as the first group; stearic acid, zinc stearate, zinc oxide Weigh for the second group; weigh the DCP and blowing agent for the third group.

[0054] In the embodiment of the present invention, the weighed components are mixed: first, the first group of materials is poured into the internal mixer, and the machin...

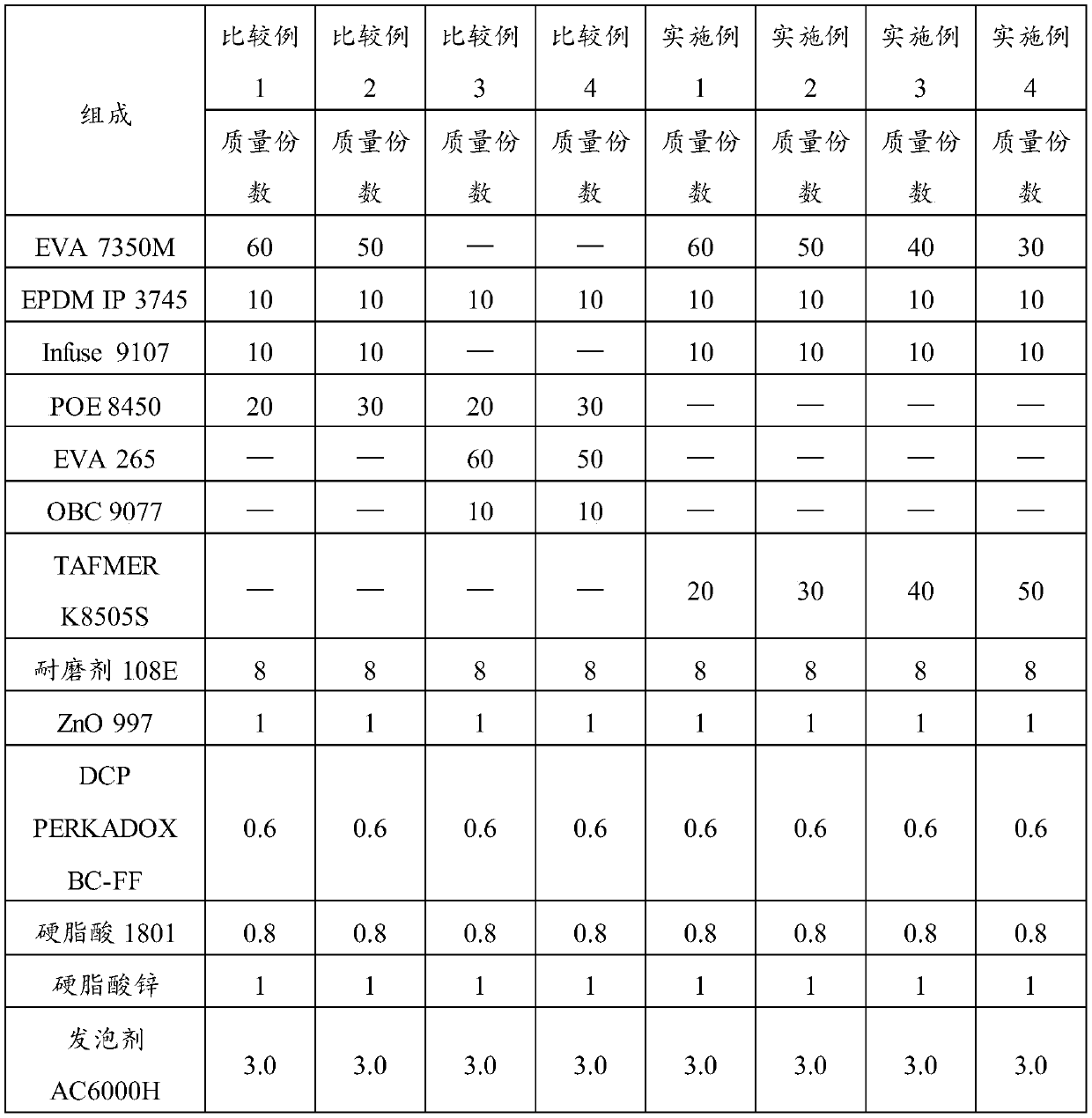

Embodiment 1

[0064] Weighing: According to the dosage of the formula in Table 1, the main plastic materials such as EVA / EPDM / OBC / special polyolefin elastomer are weighed as the first group, and stearic acid, zinc stearate, and zinc oxide are weighed as the second group. Good; DCP and blowing agent are good for the third group.

[0065] Mixing: first pour the first group of materials into the internal mixer, and start the machine, when the temperature rises to 80-85 degrees, pour the first group of materials, and mix for 20 minutes; when the temperature rises to 90-95 degrees Pour in the second group of materials and knead for 5 minutes; when the temperature rises to 100-110 degrees, pour in the third group of materials, knead for 5 minutes, and pour out the mixed materials.

[0066] Material making: Pour the mixed material into the material making machine, and adjust the temperature of the first, second, third and fourth zones to 75, 80, 85 and 90 degrees respectively. And, the screw spee...

Embodiment 2-20

[0071] According to the steps of Example 1, the formulations are shown in Table 1, Table 2, and Table 3, and high torsion-resistant foam materials were prepared respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com