A flexible socket wrench

A flexible sleeve and flexible technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of reaching in and out that cannot be turned, and achieve the effects of flexible and convenient disassembly, reliability assurance, and good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

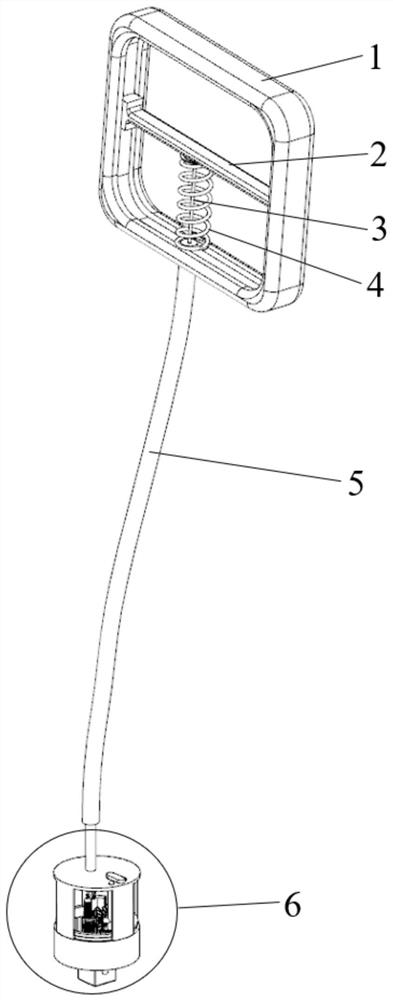

[0040] In this example, if figure 1 , figure 2 As shown, the flexible socket wrench includes a handle 1, a sliding rod 2, a wire drawing 3, a spring A4, a flexible sleeve 5, and a connector 6. The structural relationship is as follows:

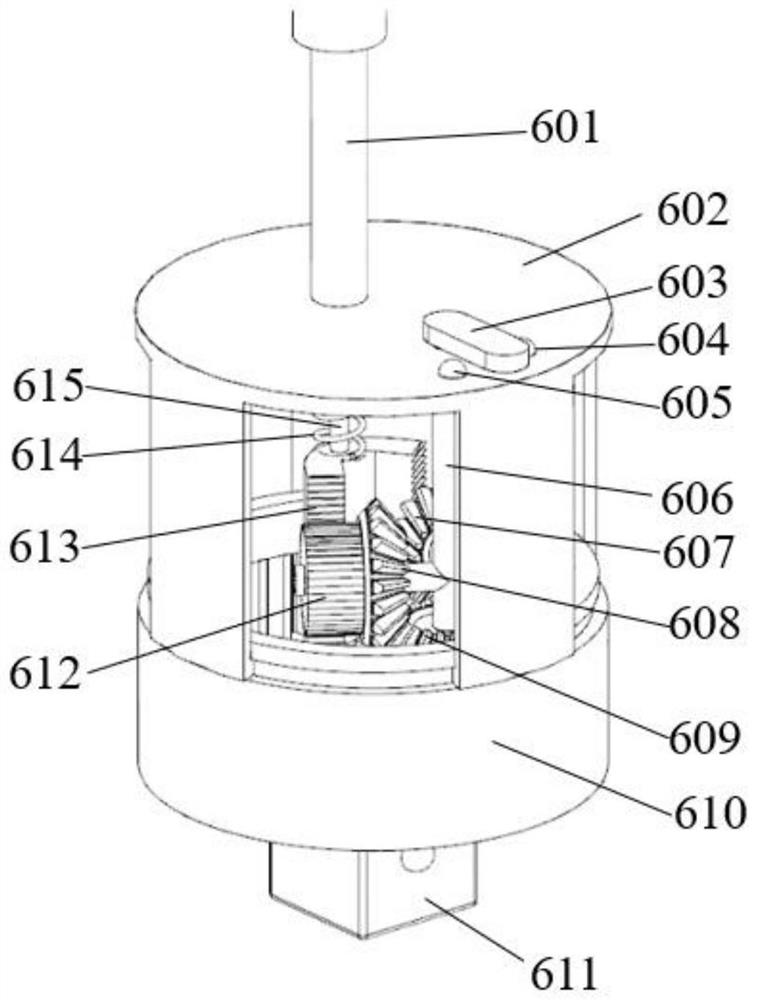

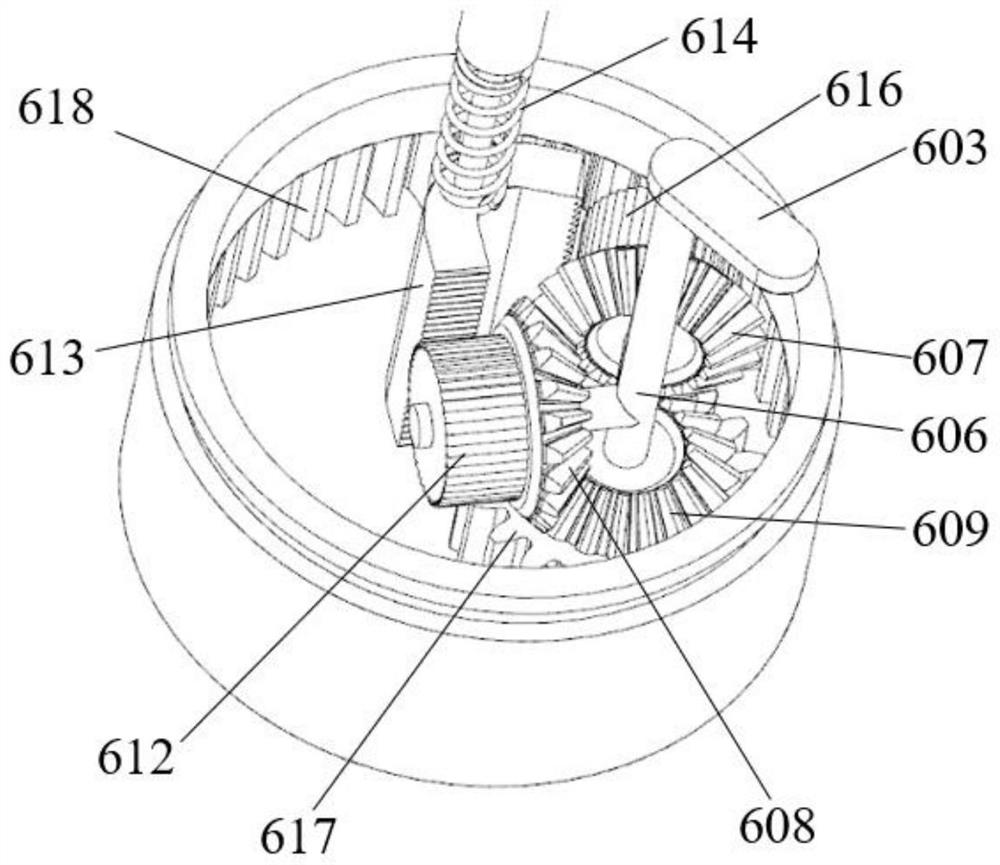

[0041] The upper end of the flexible sleeve 5 is fixedly connected to the lower end of the handle 1, the sliding rod 2 is slidably installed in the handle 1, the upper and lower ends of the spring A4 are respectively fixedly installed between the sliding rod 2 and the handle 1, and the drawing wire 3 passes through the upper end of the spring A4 and is fixedly tied to the sliding On the pull rod 2, the drawing wire 3 also passes through the tube of the flexible sleeve 5. The lower end of the drawing wire 3 is connected to the upper end of the cylindrical guide rod 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com