A kind of honeycomb support and module assembly for installing module assembly

A technology for installing modules and components, which is applied in the field of honeycomb support and module components, can solve the problems of low installation accuracy of module components, and achieve the effects of easily ensuring dimensional accuracy, improving maintenance convenience, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

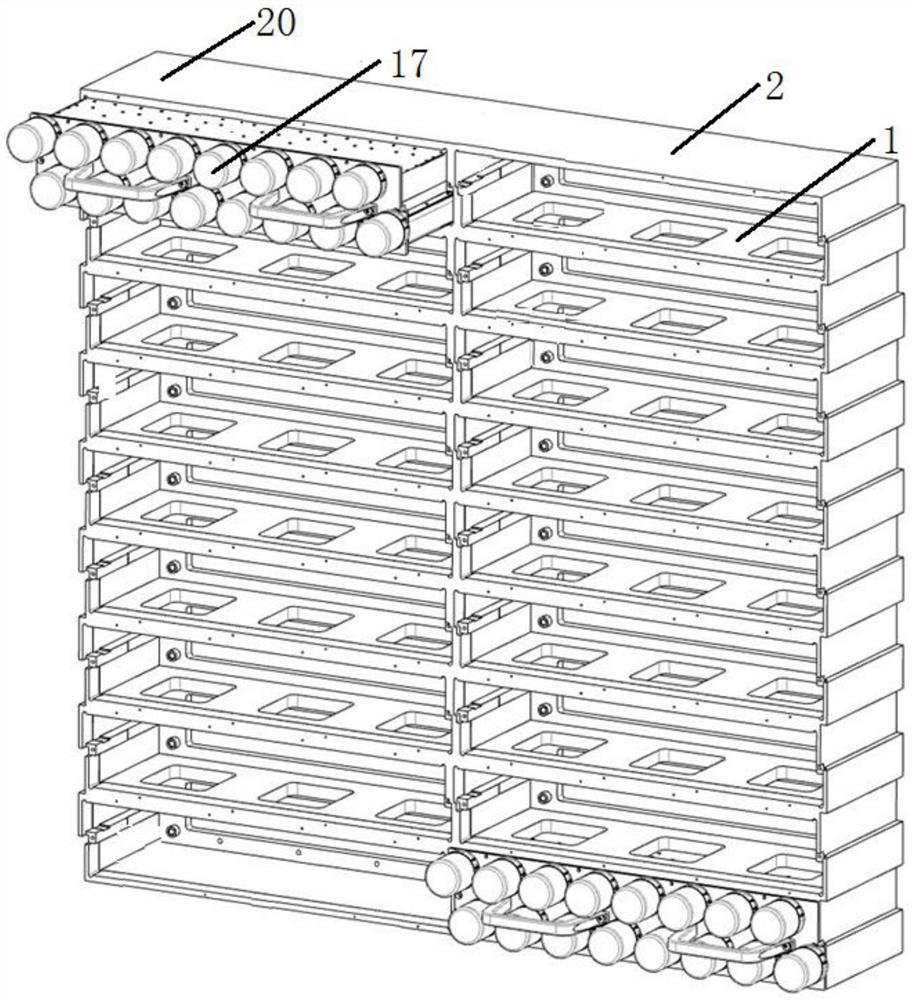

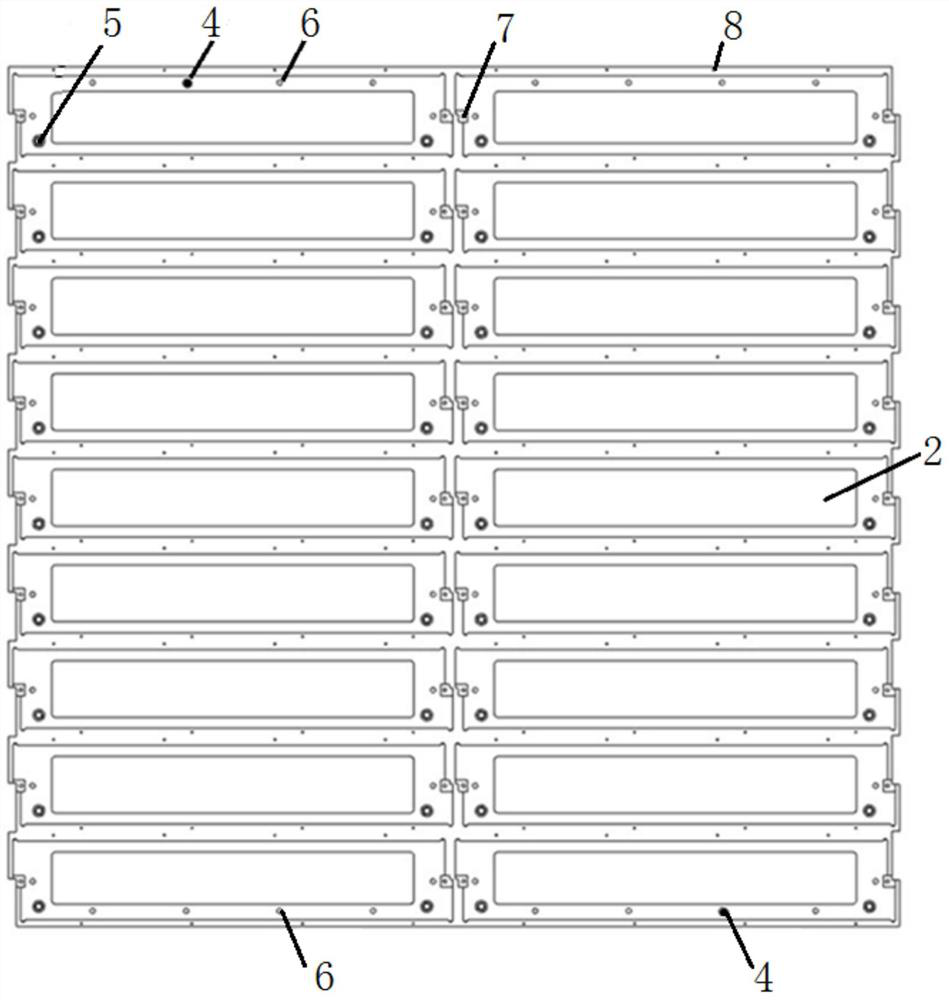

[0031] Such as figure 1 , this embodiment provides a module assembly 20, including a honeycomb support 2 and a DAMT module 17 fixed in the cavity structure of the support unit 1 of the honeycomb support. The weight of the honeycomb support 2 is 120Kg, and the external dimensions are length×width×height=1152mm ×1120mm×224mm, obtained by arranging the support unit 1 in a 2×9 array, and the DAMT module 17 is placed in the support unit 1 .

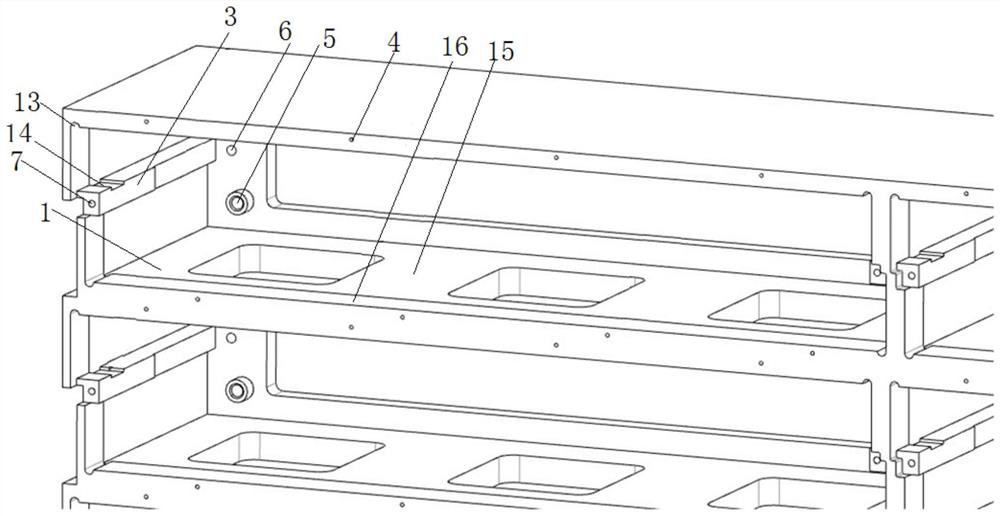

[0032] Such as figure 2 , the support unit 1 is a thin-walled rectangular cavity structure, the front end is provided with a first opening, the rear end is provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com