A high and low pressure mixed atomizing nozzle

A mixed atomization, high and low pressure technology, applied in the direction of spray device, liquid spray device, etc., can solve the problem of no atomization effect, and achieve the effect of improving equipment intelligence, reasonable design, and easy uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

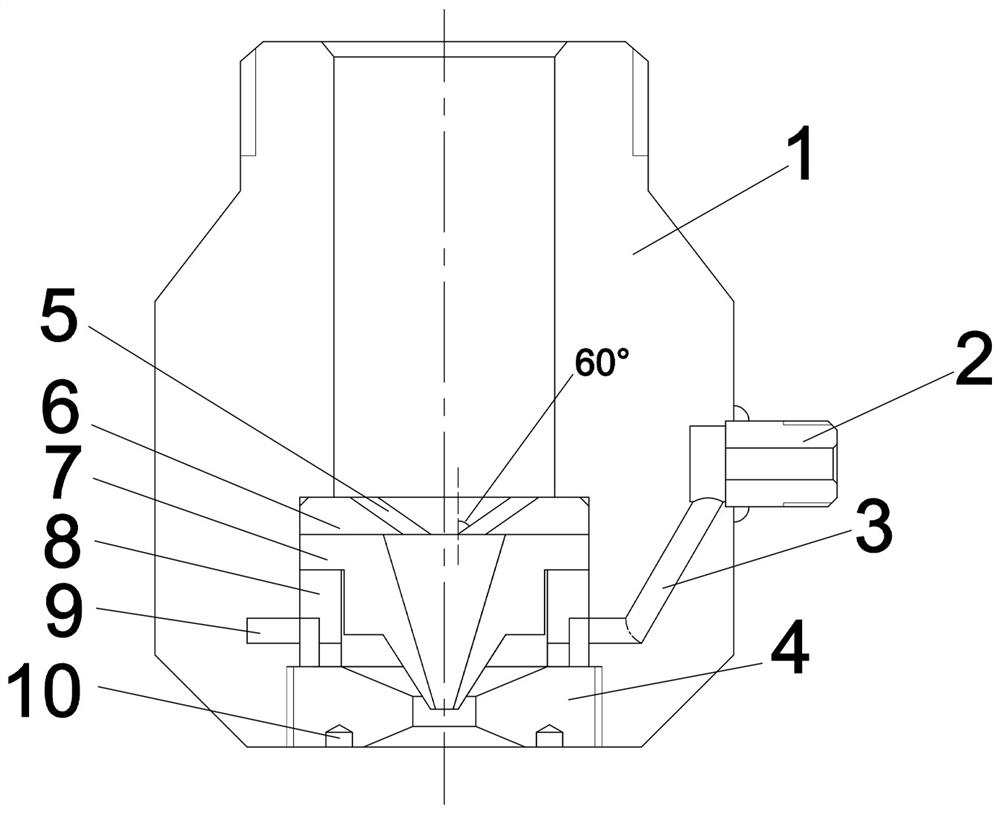

[0032] When the nozzle of the present invention is working, the low-pressure desuperheating medium is rotated and atomized for the first time through the rotating inclined hole 5, and then directly reaches the inner cavity of the nozzle 4 through the conical narrowing cavity flow channel inside the conical valve core 7, and the conical constricting cavity The cavity flow channel can maximize the flow rate at the outlet, which is helpful for the atomization of the low-pressure desuperheating medium.

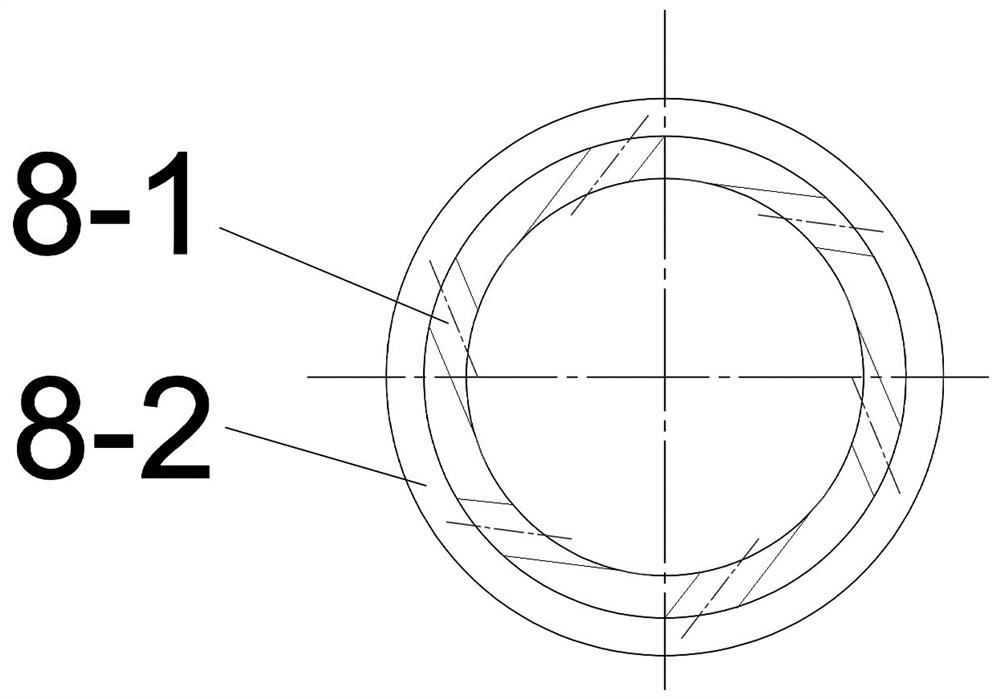

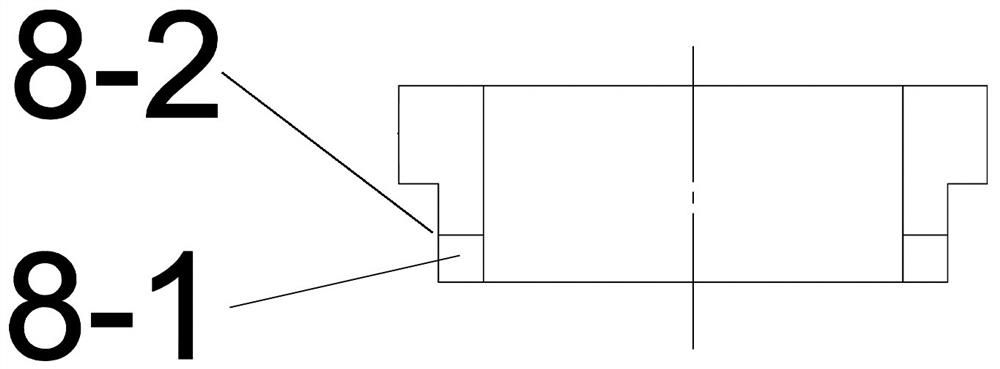

[0033] Due to the small pressure difference between the low-pressure desuperheating medium and the superheated steam in the above design, it is not enough to rely on the pressure difference to achieve a satisfactory atomization effect, so it is necessary to introduce another high-temperature and high-pressure medium to assist. The high-temperature and high-pressure medium enters the high-pressure flow inside the shell 1 through the threaded joint 2 The channel 3 then enters the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com