Adsorption material based on modified sodium alginate microspheres and preparation method and application of material

A technology of sodium alginate and adsorption material, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult recycling, poor mechanical strength, difficult granulation, etc., and achieve a simple preparation process. , Solve the effect of poor mechanical strength, good stability and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An adsorption material based on modified sodium alginate microspheres and a preparation method thereof, comprising the following steps:

[0030] Step 1: Dissolve 1g of sodium alginate and 1g of polyvinyl alcohol in 25mL of deionized water, heat at 80°C, stir well, then add calcium chloride boric acid solution dropwise (the mass concentration of boric acid solution is 5%, chlorine Gel pellets are formed in the mass concentration of calcium chloride (10%);

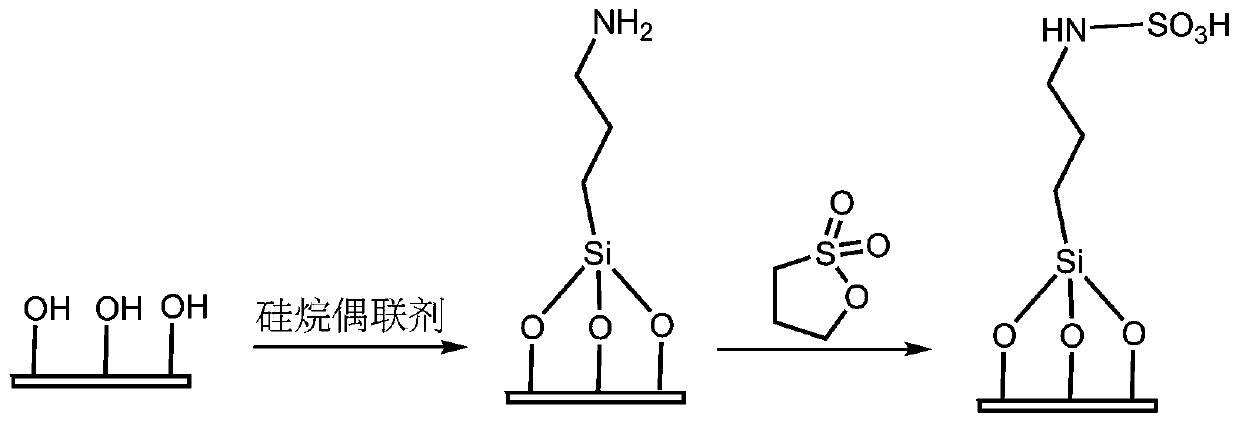

[0031] Step 2: Wash the gel balls with deionized water at room temperature, add 25 mL of 1% KH550 aqueous solution, and stir for 12 hours;

[0032] Step 3: Disperse the above product in 25mL of toluene, add 1g of 1,3-propane sultone and react for 12h;

[0033] Step 4: After the reaction, rinse and dry with toluene, ethanol and deionized water in sequence to obtain the modified sodium alginate microsphere adsorption material.

Embodiment 2

[0035] An adsorption material based on modified sodium alginate microspheres and a preparation method thereof, comprising the following steps:

[0036] Step 1: Dissolve 1g of sodium alginate and 1.5g of polyvinyl alcohol in 30mL of deionized water by heating at 80°C, stir well, then add calcium chloride boric acid solution dropwise (mass concentration of boric acid solution is 2%, chlorine Gel pellets are formed in the mass concentration of calcium chloride (5%);

[0037] Step 2: Wash the gel balls with deionized water at room temperature, add 30 mL of 4% KH550 aqueous solution, and stir for 12 hours;

[0038] Step 3: Disperse the above product in 25mL of toluene, add 1g of 1,3-propane sultone and react for 12h;

[0039] Step 4: After the reaction, rinse and dry with toluene, ethanol and deionized water in sequence to obtain the modified sodium alginate microsphere adsorption material.

Embodiment 3

[0041] An adsorption material based on modified sodium alginate microspheres and a preparation method thereof, comprising the following steps:

[0042] Step 1: Dissolve 1g of sodium alginate and 8g of polyvinyl alcohol in 30mL of deionized water by heating at 80°C, stir well, then add calcium chloride boric acid solution dropwise (mass concentration of boric acid solution is 1%, chlorination The mass concentration of calcium is 1%) to form gel beads;

[0043] Step 2: Wash the gel balls with deionized water at room temperature, add 30 mL of 4% A171 aqueous solution, and stir for 20 hours;

[0044] Step 3: Disperse the above product in 25mL of toluene, add 5g of 1,3-propane sultone and react for 20h;

[0045] Step 4: After the reaction, rinse and dry with toluene, ethanol and deionized water in sequence to obtain the modified sodium alginate microsphere adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com