An electrical machine with a stator having multiple sections winding coil and switch combinations

A combination of switches and stator winding coil technology, applied to the shape/style/structure of winding conductors, control of generators, AC motor control, etc., can solve the problem of increased cost of the controller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

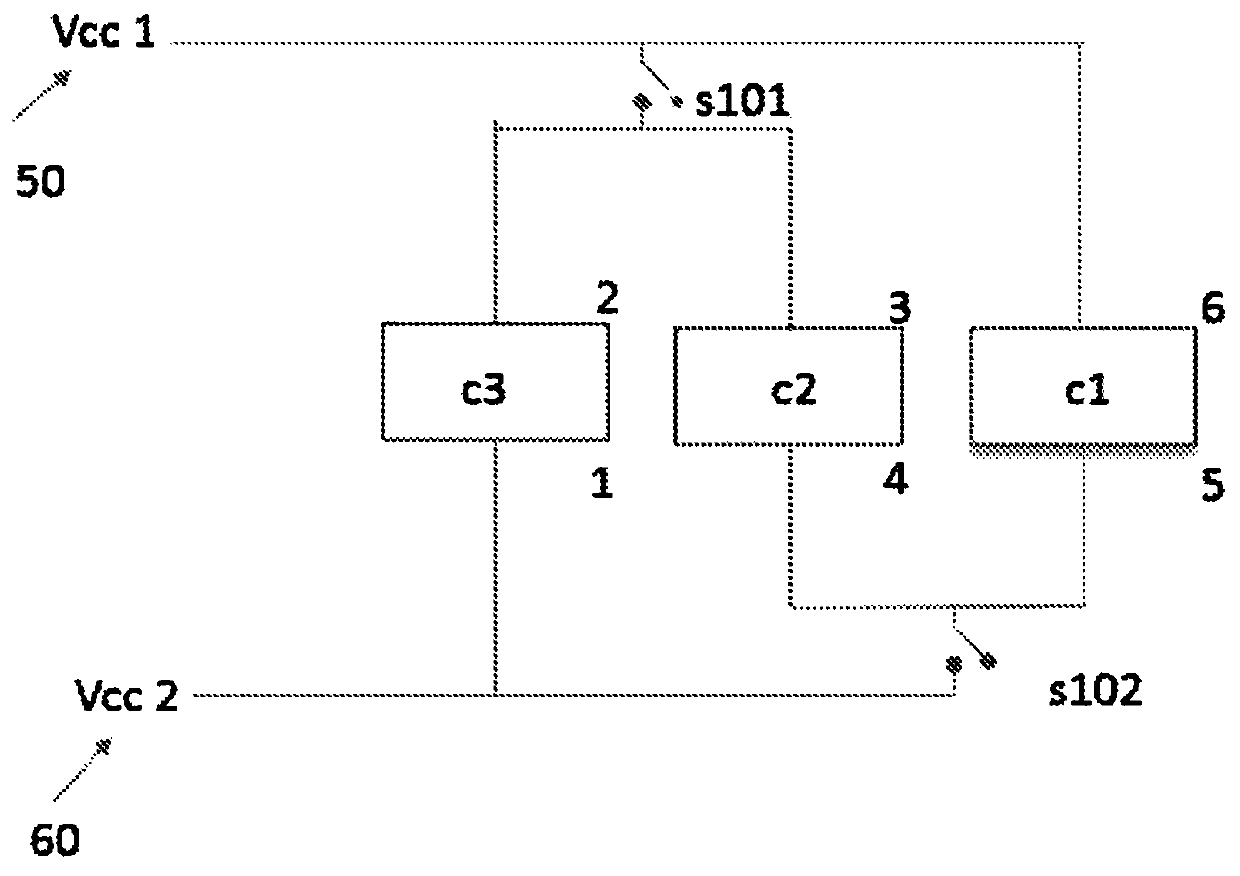

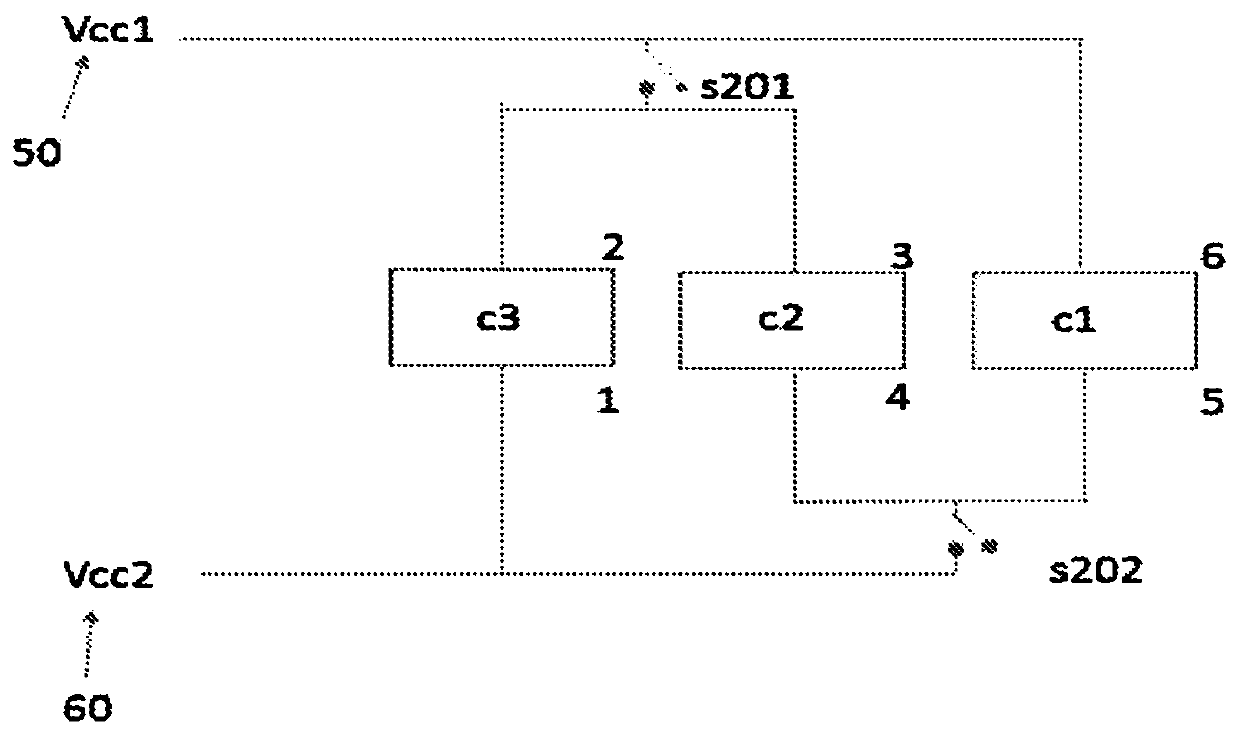

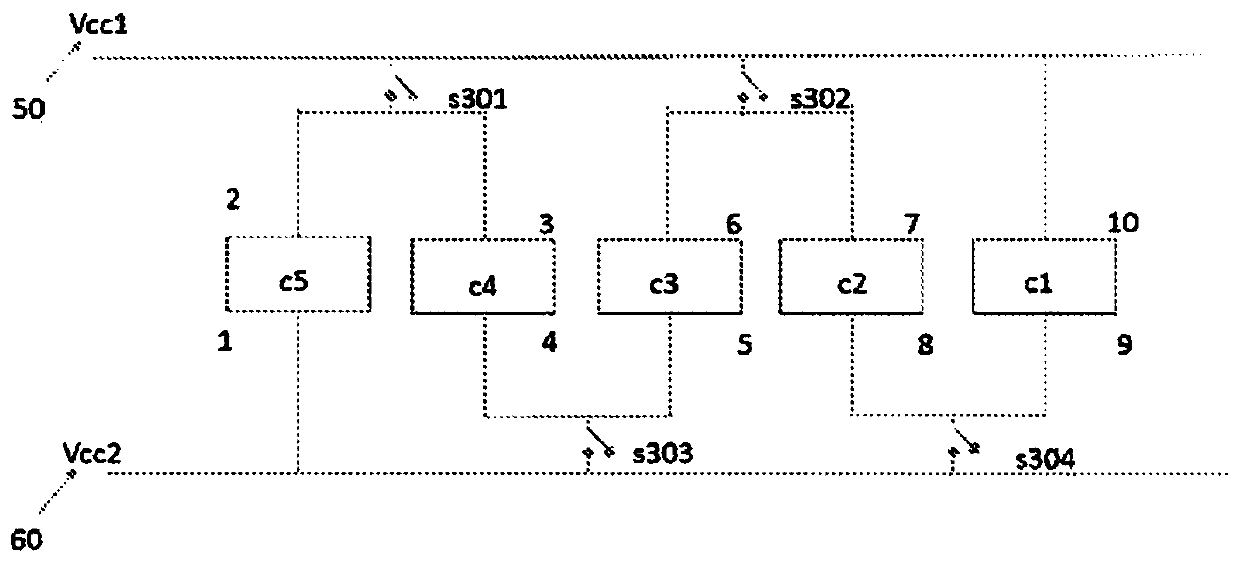

[0037] An integrated starter generator (ISG) or traction motor requires a high starting torque from the start. To generate this starting torque, the motor was originally designed with a high K t . In order to design with higher K t motors require more turns per phase. Instead of having all the turns as a coil with a single segment, a coil with multiple segments is proposed. These coils with multiple segments are wound on the same tooth of the stator. Then take out the starting end line and the end line of each section of the coil and connect the starting end line and the end line through the switch. Such as figure 1As shown, during start-up, each section of the coil is connected in such a way that the end of the first section of coil 3,5 is connected with the beginning of the next section of coil 2,4. The starting end 6 of the first section of coil C1 is connected to the phase terminal of the controller 50 and the end line of the last section 1 of coil C3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com