Silicon controlled energy-saving stepless speed regulating fan

A stepless speed regulation and fan technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve problems such as complex motor manufacturing, limited speed regulation range, and enlarged motor size, so as to improve speed regulation Range, precise stepless speed regulation, and the effect of increasing the maximum speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

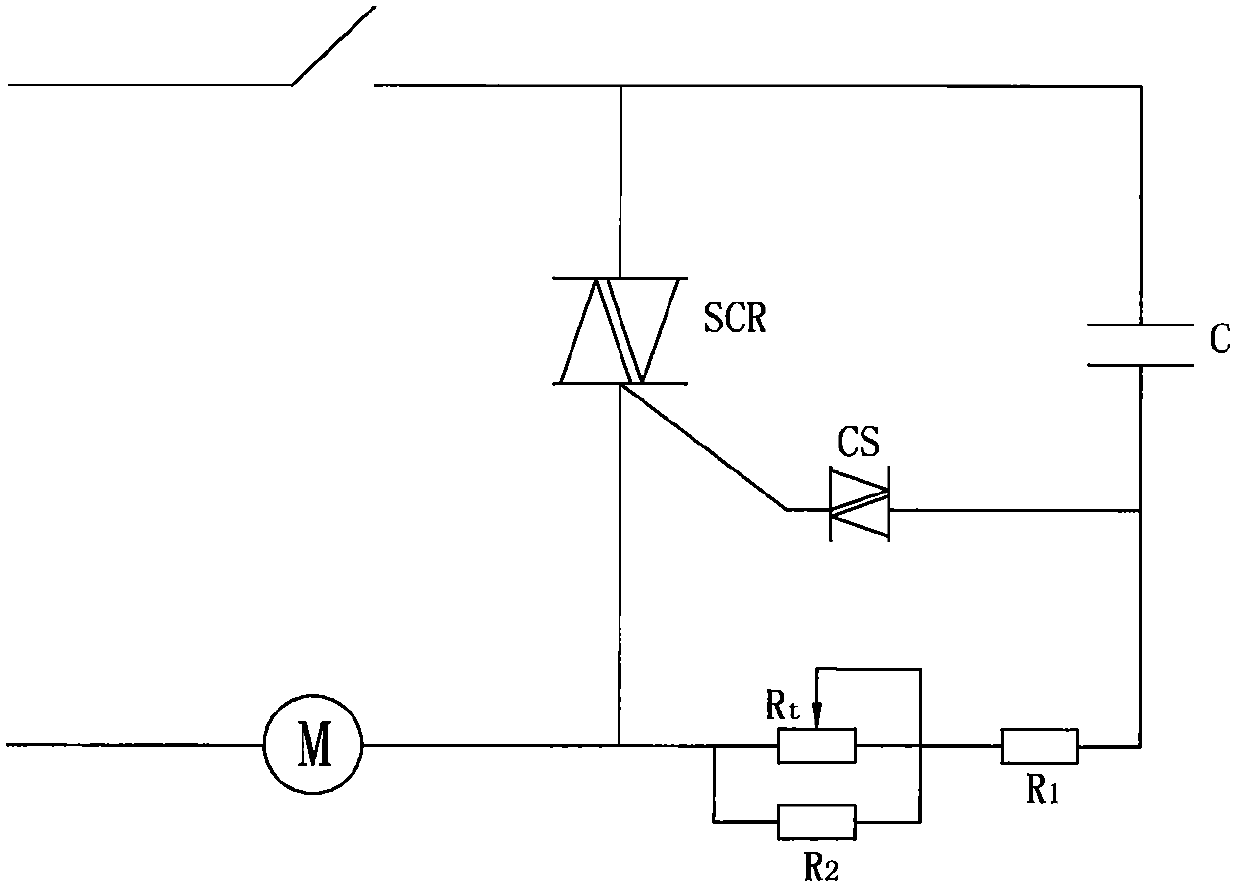

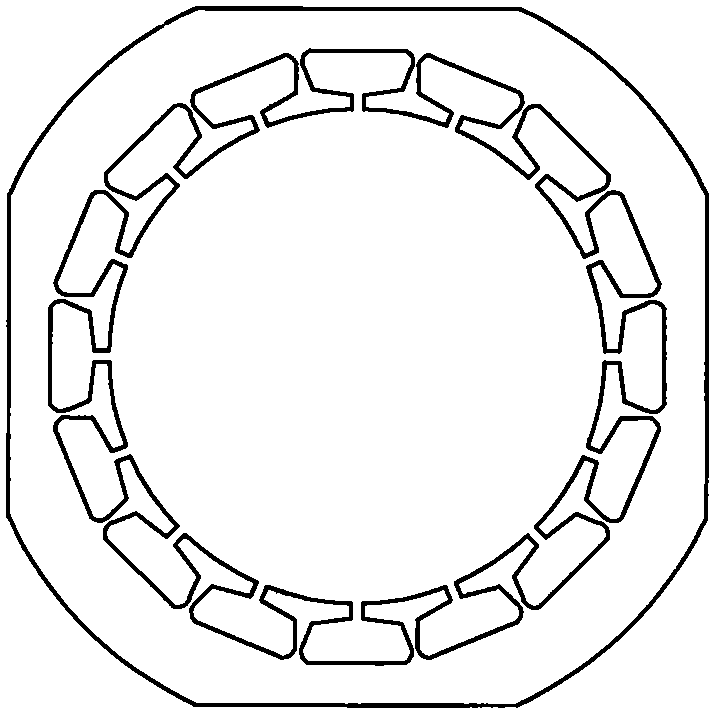

[0013] combined with figure 1 , attached figure 2 , a thyristor energy-saving stepless speed regulation fan of the present invention, which includes a potentiometer R t and with potentiometer R t The first resistor R in series 1 , capacitor C, first resistor R 1 To protect the circuit, the fan also includes a trigger diode CS, a thyristor SCR and a fan motor M, wherein one end of the trigger diode CS is connected to the control end of the thyristor SCR, and the other end is connected to the first Resistance R 1 point in series with capacitor C, the SCR through its output terminal and the potentiometer R t , the first resistor R 1 And the series circuit formed by capacitor C is connected in parallel with the fan motor M, and the fan motor M includes a stator and a rotor, wherein the stator includes a stator core and a stator coil wound on the stator core. There are sixteen wire slots, and the stator coil composed of main and auxiliary windings is installed in the wire s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com