Preparation method of graphene-coated positive electrode material of lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of weakening battery processability and safety performance, and achieve the goal of reducing difficulty, increasing capacity, and reducing DC internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

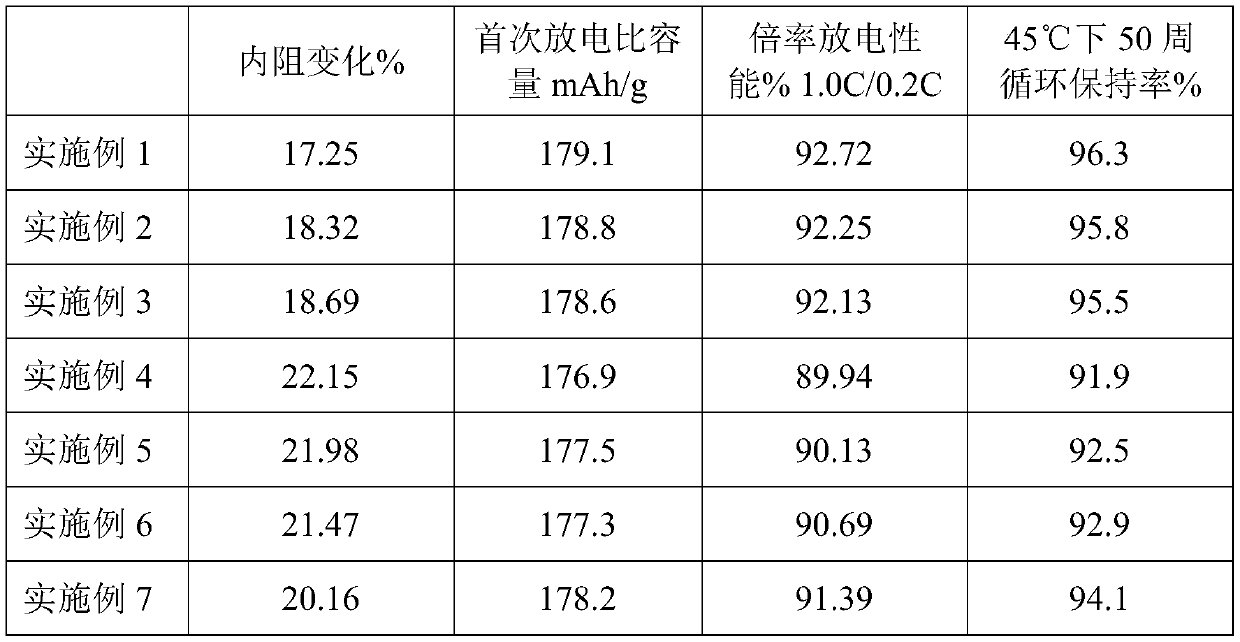

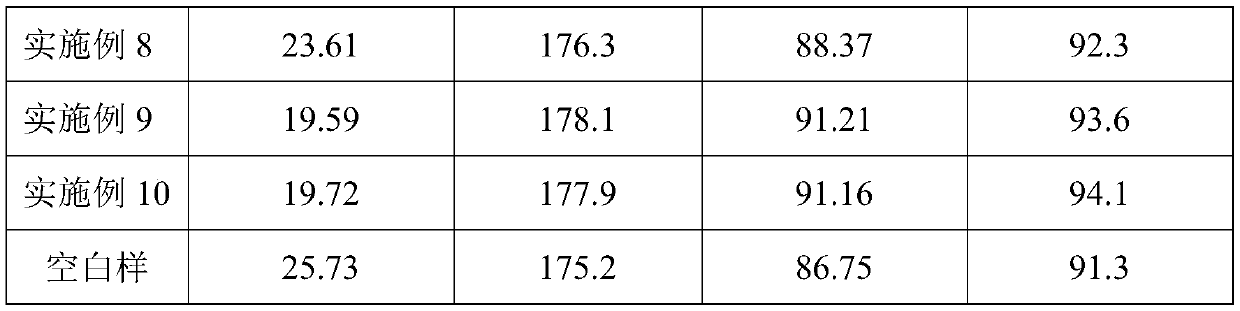

Examples

preparation example Construction

[0021] In some embodiments, the preparation method of the graphene-coated lithium-ion battery cathode material of the alignment comprises the following steps:

[0022] (1) Preparation of mixed slurry;

[0023] (2) After the mixed slurry is subjected to the action of an electromagnetic field, it is then dried to obtain a powder substance;

[0024] (3) Composite the dried powder material to obtain an aligned graphene-coated lithium-ion battery positive electrode material.

[0025] In some embodiments, the magnetic induction of the electromagnetic field is 0.3-0.8T; preferably, the magnetic induction of the electromagnetic field is 0.4-0.7T; more preferably, the magnetic induction of the electromagnetic field is 0.6T.

[0026] In some embodiments, the drying process uses spray drying, and the spray drying temperature is 120-300°C; preferably, the spray drying temperature is 150-270°C; more preferably, the spray drying temperature is 250°C.

[0027] In some embodiments, the pres...

Embodiment 1

[0052] Embodiment 1 of the present invention provides a kind of lithium-ion battery anode material coated with graphene of alignment, and its preparation method comprises the following steps:

[0053] (1) Preparation of mixed slurry;

[0054] (2) After the mixed slurry is subjected to the action of an electromagnetic field with a magnetic induction intensity of 0.6T, it is spray-dried to obtain a powder substance, wherein the spray-drying temperature is 250°C, the spray-drying atomization gas pressure is 0.2MP, and the spray-drying uses nitrogen as a protective gas;

[0055] (3) Composite the dried powder material to obtain the lithium-ion battery anode material coated with graphene in an orientation arrangement, the rotating speed of the composite process is 4000rpm, and the composite time of the composite process is 30min;

[0056] The preparation process of mixed slurry comprises the following steps:

[0057] (1) Mix binder-1 and organic solvent-1, stir at room temperatur...

Embodiment 2

[0067] Embodiment 2 of the present invention provides a lithium-ion battery anode material coated with graphene in alignment, and its preparation method comprises the following steps:

[0068] (1) Preparation of mixed slurry;

[0069] (2) After the mixed slurry is subjected to the action of an electromagnetic field with a magnetic induction intensity of 0.8T, it is spray-dried to obtain a powder substance, wherein the spray-drying temperature is 300°C, the spray-drying atomization gas pressure is 0.30MP, and the spray-drying uses nitrogen as a protective gas;

[0070] (3) Composite the dried powder material to obtain the lithium-ion battery anode material coated with graphene in an orientation arrangement, the rotating speed of the composite process is 6000rpm, and the composite time of the composite process is 60min;

[0071] The preparation process of mixed slurry comprises the following steps:

[0072] (1) Mix binder-1 and organic solvent-1, and stir at room temperature f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com