Elliptical trailing cable for overhead vehicle

An elliptical and dragging technology, applied in the direction of insulated cables, bendable cables, flat/ribbon cables, etc., can solve problems affecting the safety of use, affecting cable bending, and easy entanglement, etc., to improve signal interference capabilities, Guaranteed bending and flexibility, and improved tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

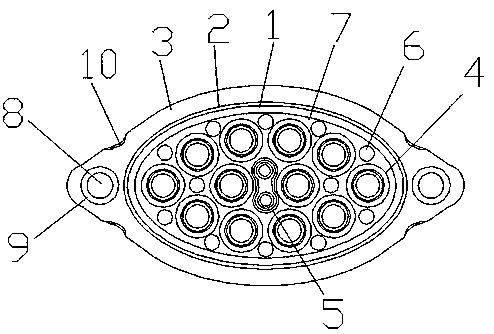

[0028] Reference Figure 1-3 , An elliptical towing cable for overhead cranes, comprising a cable core, an insulating layer wrapped around the cable core 1, an armor layer wrapped around the insulating layer 1, a sheath layer 3 wrapped outside the armor layer 2, It is characterized in that the cable core is composed of a main wire core 4, a ground wire core 5, a tensile rope 6 and a filler 7. The cable core is specifically elliptical, and the ground wire core 5 is set at the center of the cable core; the ground wire core 5 consists of Ground wire conductor 501, ground wire insulation 502, ground wire filling layer 503, steel tube sheet 504 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com