Gas sensing module and preparation method and applications thereof

A technology of gas sensing and gas-sensing sensing materials, applied in the field of new functional materials, can solve the problems of poor material stability and sensitivity, large noble metal particles, and low resistance, and achieve simple preparation methods, large specific surface area, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

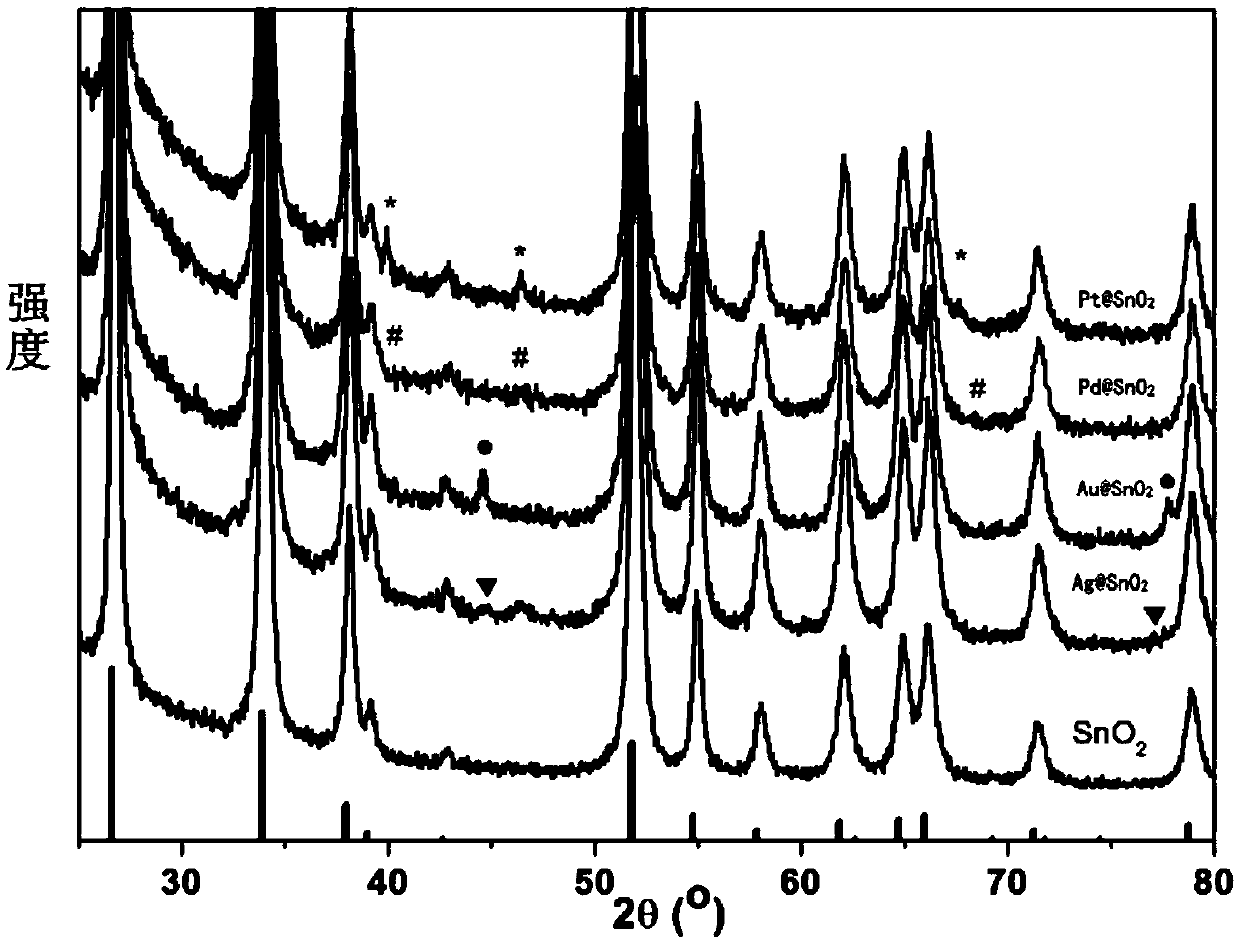

[0052] According to the preparation method of the gas sensing module of the present invention, the method comprises:

[0053] 1) Mixing a tin-containing compound, a C2-C6 organic dibasic acid, hydrazine hydrate and hydrochloric acid, performing a hydrothermal reaction, and then performing solid-liquid separation to obtain a tin dioxide carrier;

[0054] 2) Loading the noble metal on the tin dioxide carrier to obtain a noble metal-loaded gas-sensitive sensing material;

[0055] 3) loading the noble metal-loaded gas-sensitive sensing material on the microsensor chip;

[0056] Wherein, the noble metal is selected from one or more of the metal elements of Group IB and Group VIII.

[0057] Preferably, the noble metal is selected from one or more of Ag, Au, Pd and Pt.

[0058] In step 1), as long as the tin-containing compound can be dissolved in an acidic aqueous solution to obtain tin cations (Sn 4+ or Sn 2+ ), preferably tin-containing inorganic salts or oxides. The tin-cont...

preparation example 1

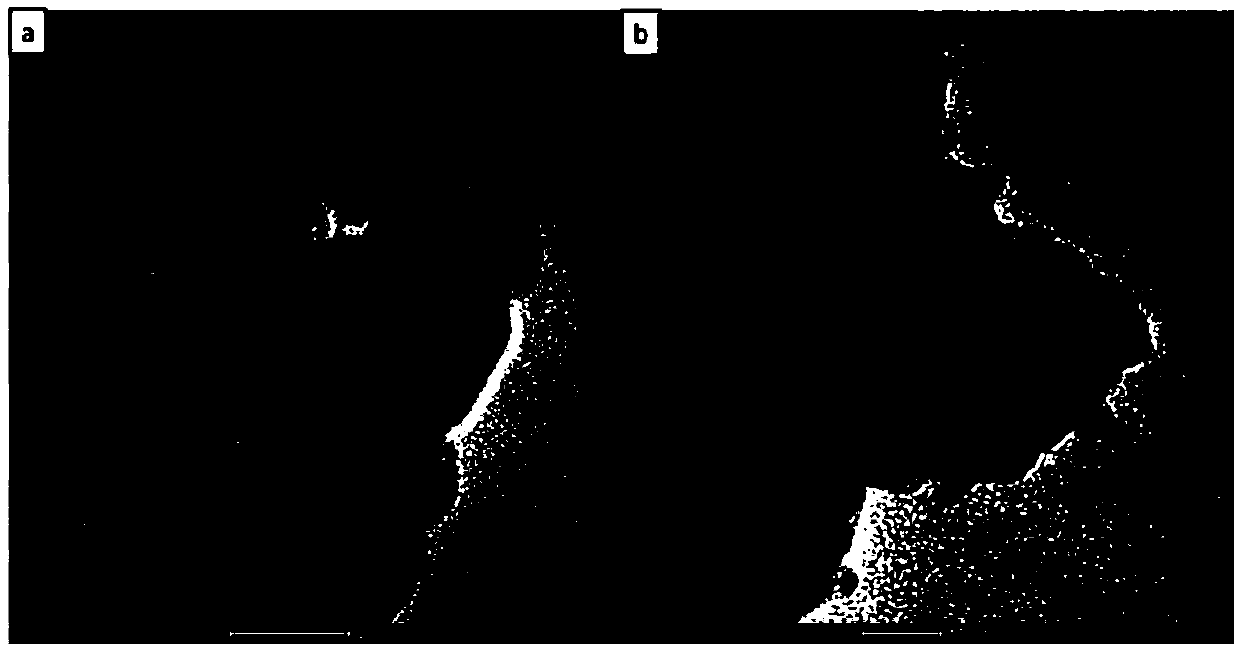

[0076] Microfabrication methods such as photolithography and evaporation are prepared on the surface of silicon wafers such as Figure 5 The shown interdigitated Au electrode (10 microns in width) was used as the sensing electrode 1, and the Au resistance wire for heating (5 microns in width) was used as the heating electrode 2, thereby obtaining a microsensor chip. And three microsensor chips are integrated and connected to a control circuit board.

Embodiment 1

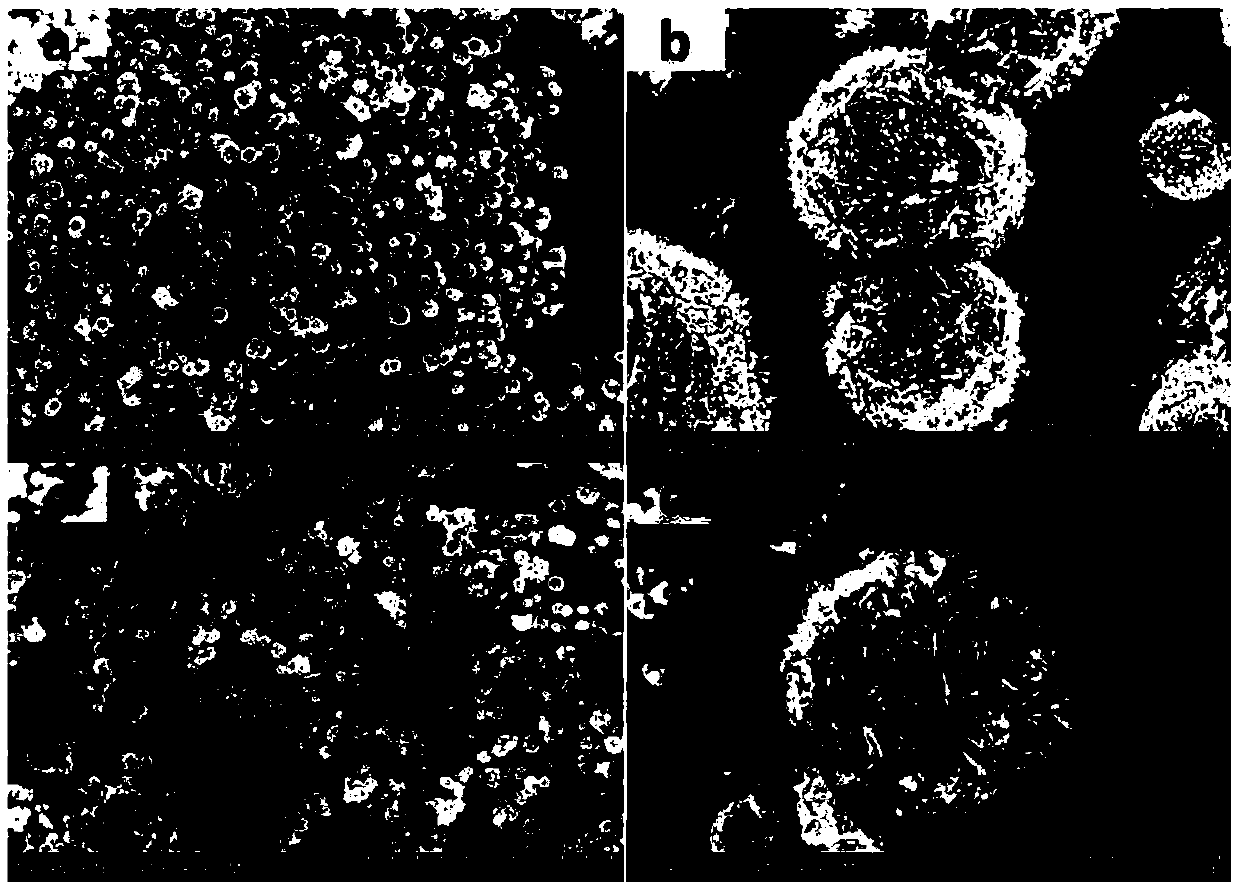

[0078] (1) Mix 1g stannous dichloride dihydrate, 2g oxalic acid and 100mL deionized water, add 0.1mL concentrated hydrochloric acid (35%), 2.16g hydrazine hydrate (50wt%), and stir to form a transparent homogeneous mixed solution;

[0079] (2) Put the above mixed solution into the reaction kettle, conduct hydrothermal treatment at 160°C for 20 hours, and centrifuge after cooling;

[0080] (3) Collect the solid precipitate, add deionized water and ultrasonically disperse for 10 min, collect by centrifugation again, and repeat 3 times to obtain tin dioxide microspheres;

[0081] (4) Weigh 0.1 g of the above-mentioned tin dioxide microspheres, add it to 10 mL of AgNO with a concentration of 1 mmol / L 3 In the aqueous solution, the xenon lamp with a power of 300W was irradiated with ultraviolet light for 20 minutes to make AgNO 3 Decompose, then centrifuge at 10,000 rpm for 5 minutes, separate the filter residue, add deionized water to wash, centrifuge again to separate the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com