Steel structure surface brick pavement construction method

A construction method and paving technology, applied in building structure, covering/lining, construction, etc., can solve problems such as lack of texture, low work efficiency, weakening the adhesion between mortar and steel columns, steel pipe columns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

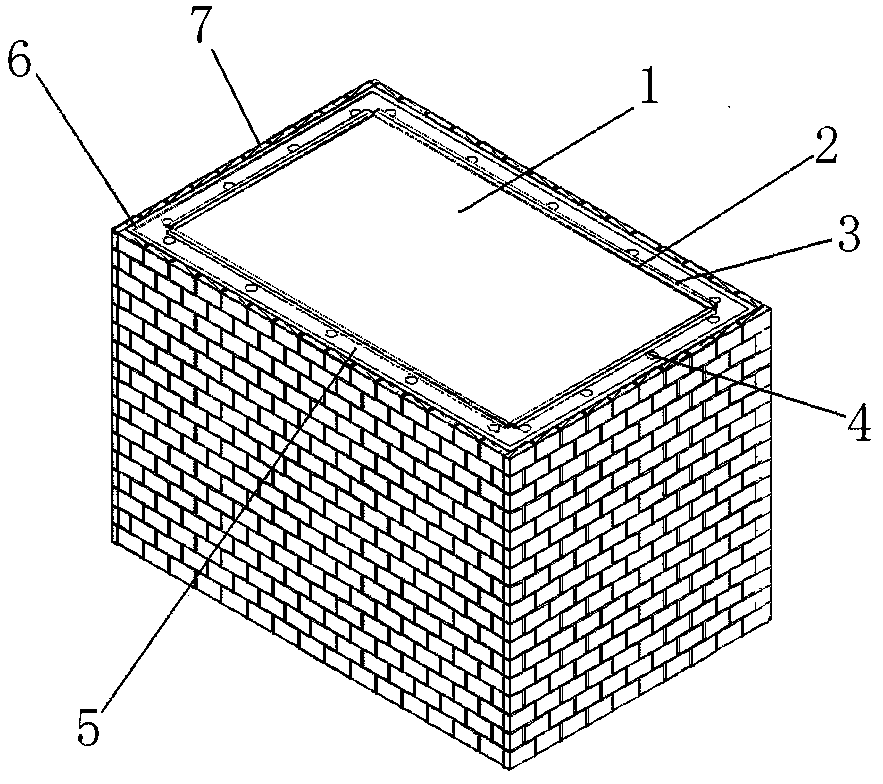

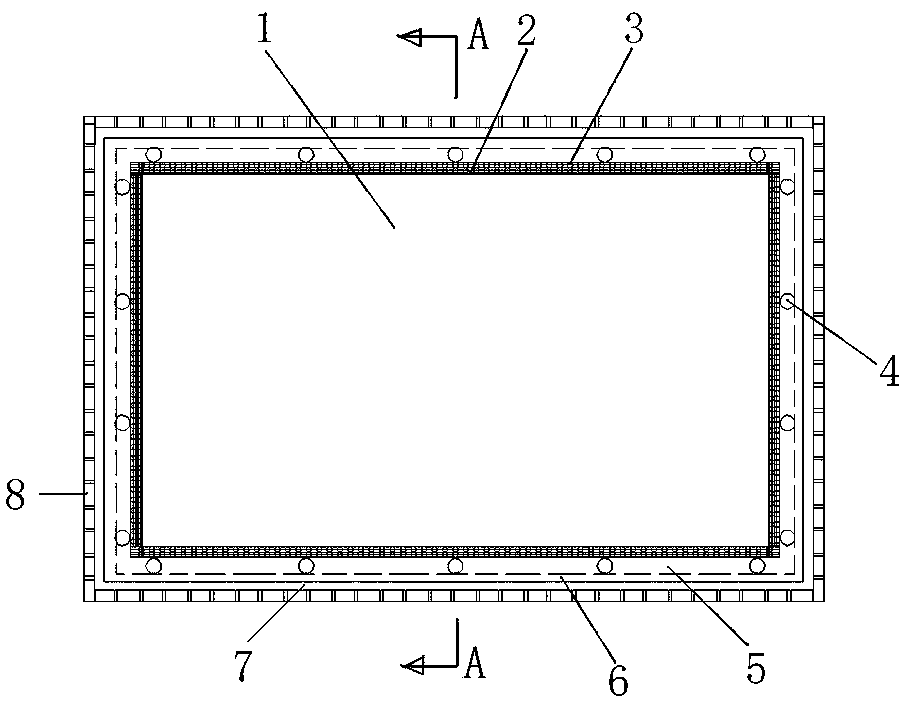

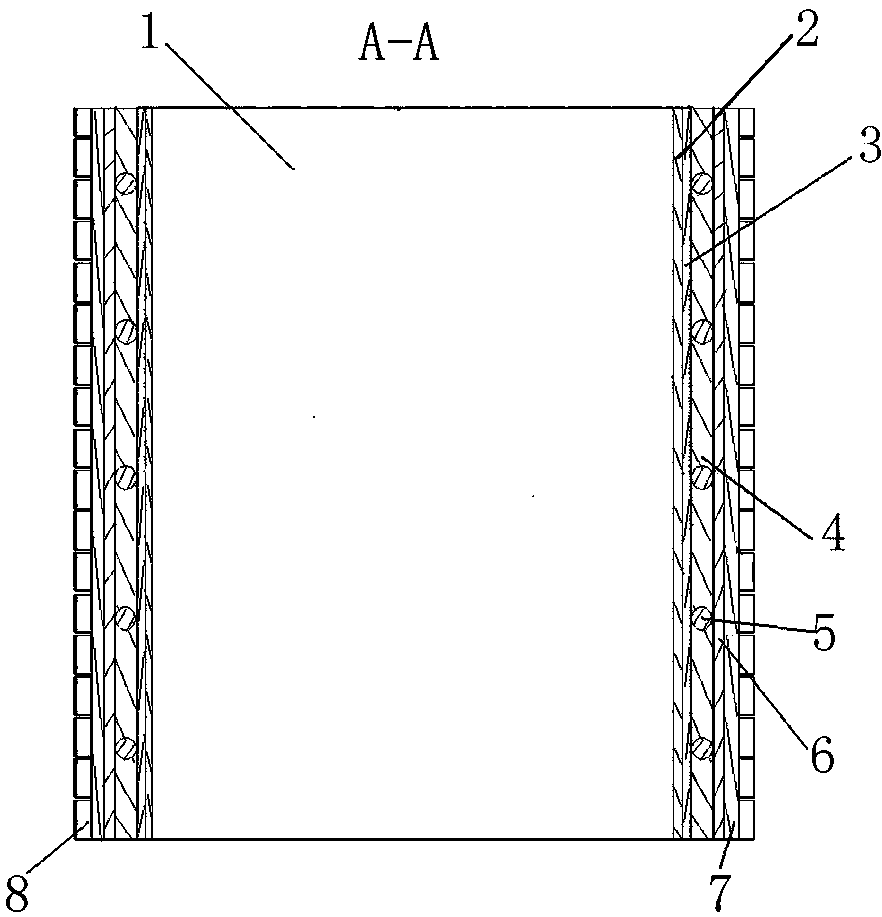

[0026] see Figure 1-4 , a kind of construction method of steel column surface brick paving of the present invention comprises the following steps:

[0027] 1) Laying of barbed wire:

[0028] Cover the surface of the steel column 1 with galvanized wire mesh A2 and galvanized wire mesh B3 with a mesh diameter of 8mm and a steel wire diameter of 0.8mm;

[0029] 2) Connection between barbed wire and steel column:

[0030] Press the galvanized wire mesh B3 upright from the outside with the steel bar A4, surround the galvanized wire mesh B3 with the steel bar B5 from the outside, and weld the galvanized barbed wire A2, galvanized barbed wire B3, steel bar A4, and steel bar B5 at intervals of 400mm by arc welding. Welded on the steel column 1;

[0031] 3) Paving of inner cement mortar A6:

[0032] Use cement mortar A6 to smear and press and completely wrap the zinc wire mesh A2, galvanized wire mesh B3 and pressure mesh reinforcement A4. The cement mortar A6, zinc wire mesh A2, ...

Embodiment 2

[0038] see Figure 1-4 , a kind of construction method of steel column surface brick paving of the present invention comprises the following steps:

[0039] 1) Laying of barbed wire:

[0040] Cover the surface of the steel column 1 with galvanized wire mesh A2 and galvanized wire mesh B3 with a mesh diameter of 10mm and a steel wire diameter of 1mm;

[0041] 2) Connection between barbed wire and steel column:

[0042] Press the galvanized wire mesh B3 upright from the outside with the steel bar A4, surround the galvanized wire mesh B3 with the steel bar B5 from the outside, and weld the galvanized barbed wire A2, the galvanized barbed wire B3, the steel bar A4, and the steel bar B5 at intervals of 500mm by arc welding. Welded on the steel column 1;

[0043] 3) Paving of inner cement mortar A6:

[0044] Use cement mortar A6 to smear and press and completely wrap the zinc wire mesh A2, galvanized wire mesh B3 and pressure mesh reinforcement A4. The cement mortar A6, zinc wir...

Embodiment 3

[0050] see Figure 1-4 , a kind of construction method of steel column surface brick paving of the present invention comprises the following steps:

[0051] 1) Laying of barbed wire:

[0052] Cover the surface of the steel column 1 with galvanized wire mesh A2 and galvanized wire mesh B3 with a mesh diameter of 12mm and a steel wire diameter of 1.2mm;

[0053] 2) Connection between barbed wire and steel column:

[0054] Press the galvanized wire mesh B3 upright from the outside with the steel bar A4, surround the galvanized wire mesh B3 with the steel bar B5 from the outside, and weld the galvanized wire mesh A2, galvanized wire mesh B3, steel bar A4, and steel bar B5 at intervals of 600mm by arc welding. Welded on the steel column 1;

[0055] 3) Paving of inner cement mortar A6:

[0056] Use cement mortar A6 to smear and press and completely wrap the zinc wire mesh A2, galvanized wire mesh B3 and pressure mesh reinforcement A4. The cement mortar A6, zinc wire mesh A2, gal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com