Assembled vibration attenuating floorslab with built-in multi-dimensional energy-consuming damping particles

A technology of damping particles and assembly, which is applied in the direction of protective buildings/shelters, building components, building structures, etc. It can solve the problems of three-dimensional vibration reduction, adverse effects, and narrow vibration reduction frequency bands, etc., to increase the structural integrity performance, reducing main body damage, and good energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

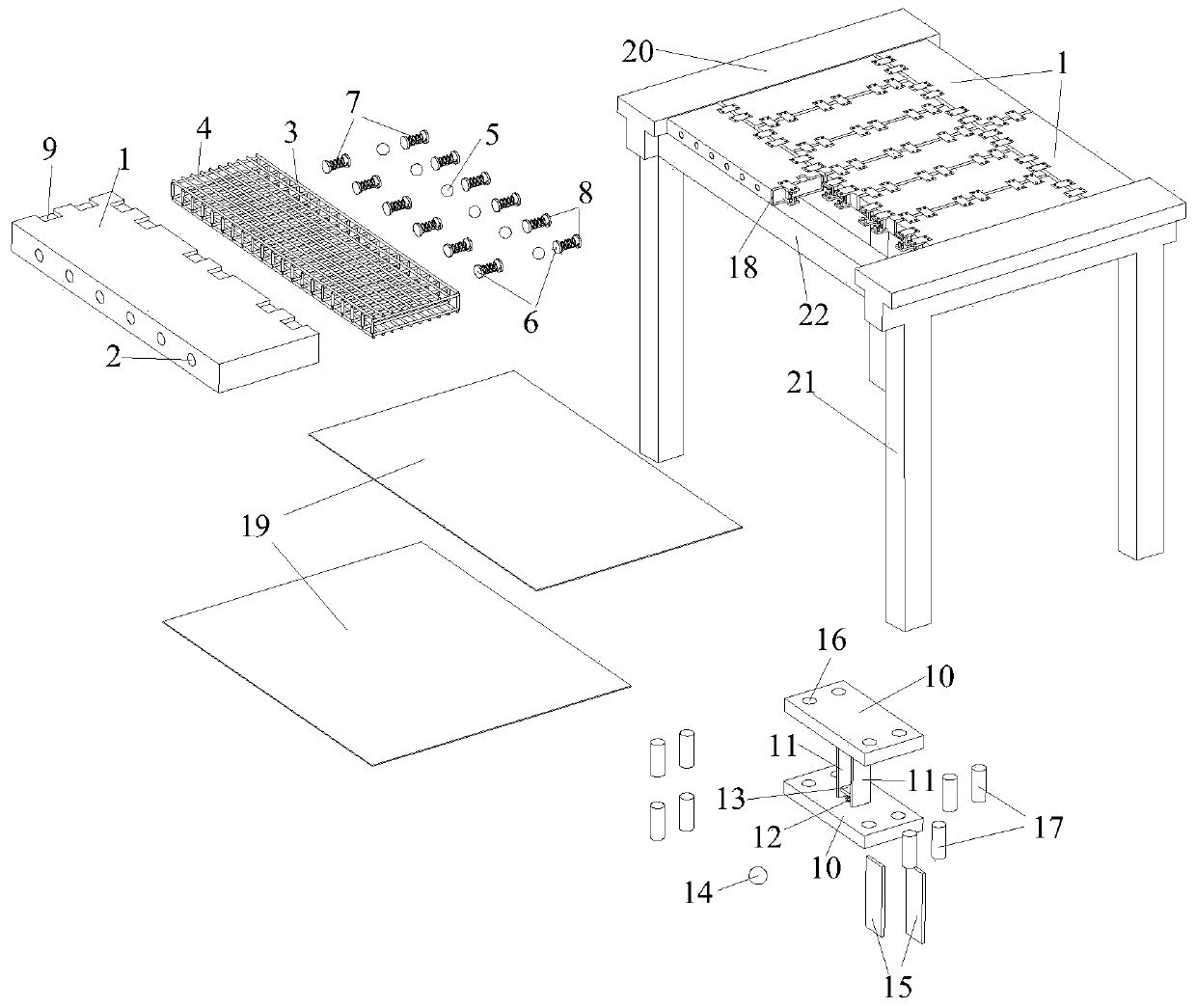

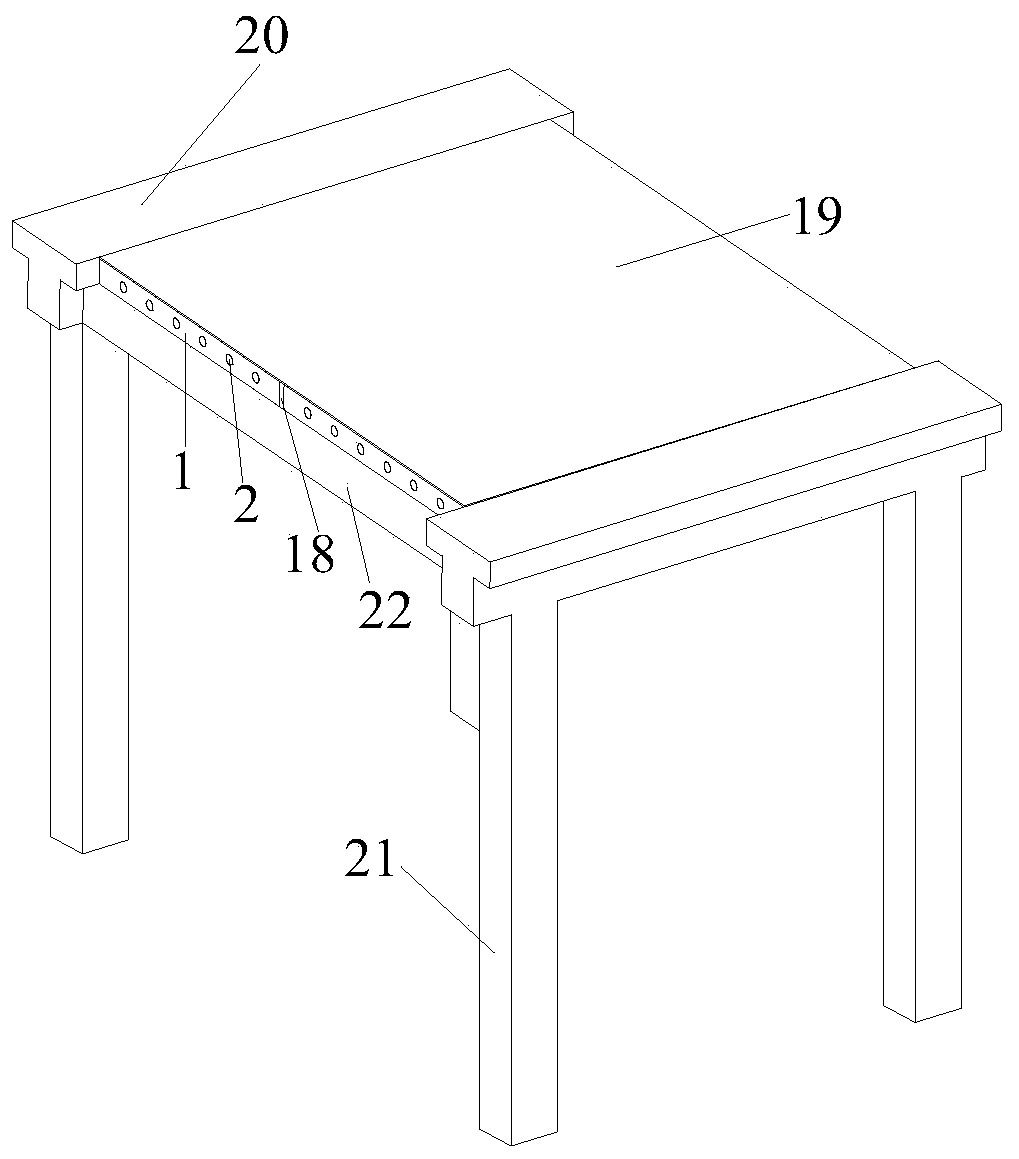

[0038] as attached figure 1 , 2 As shown, it is an embodiment of a prefabricated damping floor with built-in multi-dimensional energy-dissipating damping particles in a reinforced concrete frame structure of the present invention, including a prefabricated floor 1, reserved channels 2, longitudinal reinforcement 3, distribution reinforcement 4, horizontal Directional damping particles 5, soft hole plugs 6, horizontal springs 7, circular rebounding plates 8, recesses 9, flanges 10, webs 11, vertical springs 12, rectangular rebounding plates 13, vertical damping particles 14, side plates 15. Prefabricated holes 16, planting reinforcement 17, light material 18, sound insulation board 19, beam 20, column 21, secondary beam 22; place longitudinal reinforcement 3 and distribution reinforcement 4 in prefabricated floor 1, and prefabricate There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com