Method for making brick powder concrete from waste sintered shale brick powder

A technology of concrete and shale bricks, applied in the field of concrete, can solve problems such as increasing jobs, and achieve the effects of saving resources, improving performance, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The method for making brick powder concrete by using waste sintered shale brick powder comprises the following steps:

[0045] (1) Recycling waste sintered shale bricks, using manual hammering, preliminary crushing, and sorting to remove impurities from waste sintered shale bricks;

[0046] (2) Use a jaw crusher to crush the waste sintered shale bricks after removal of impurities, and dry them after crushing;

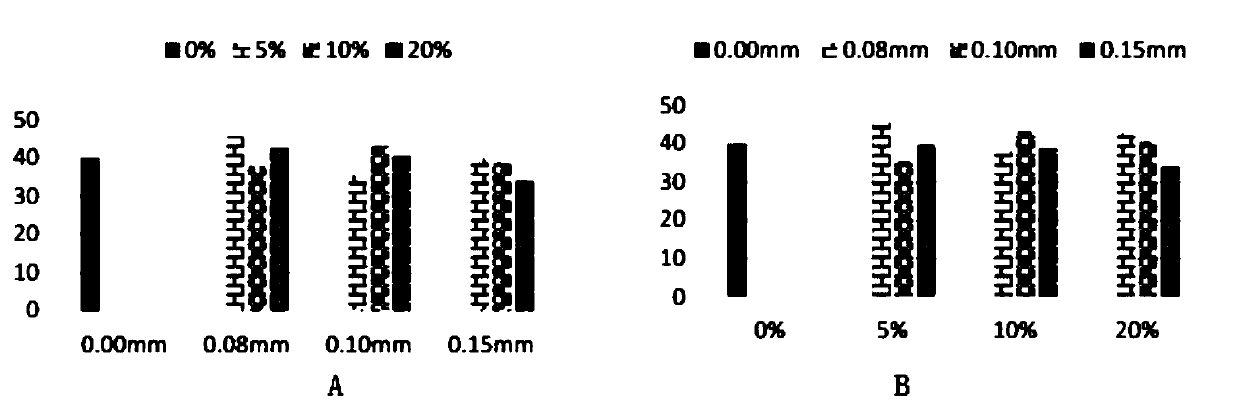

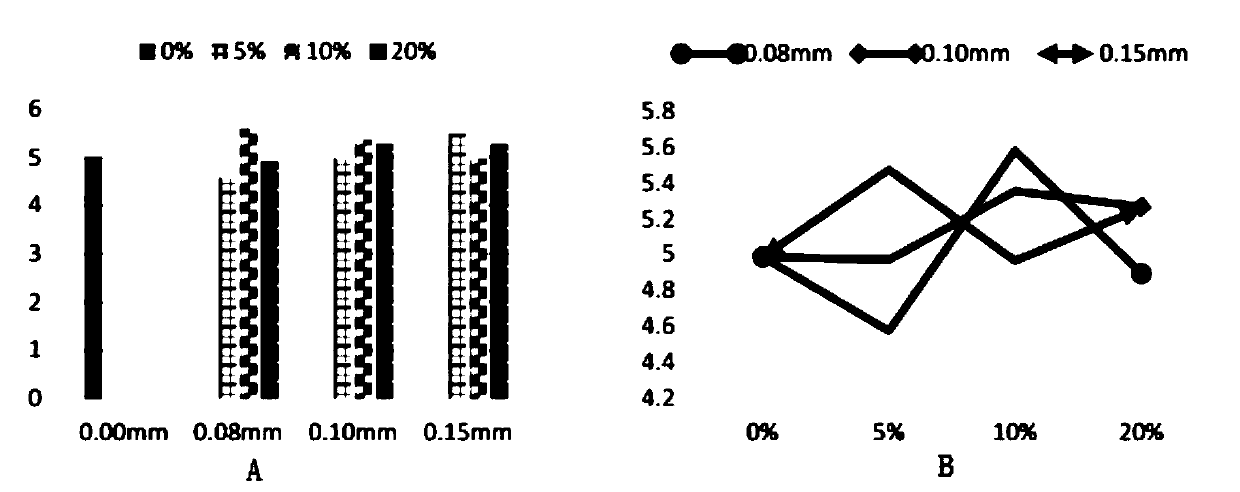

[0047] (3) Finely grind the broken waste sintered shale bricks, sieve with a vibrating sieve machine, and dry them in an oven to obtain waste sintered shale brick powder. The fineness of the waste sintered shale brick powder is 0.08 mm;

[0048] (4) In parts by weight, the raw materials used are as follows: 359 parts by weight of cement, 600 parts by weight of medium sand, 1100 parts by weight of stones with a particle size of 18 mm, 190 parts by weight of water, 246 parts by weight of waste sintered shale brick powder 3 parts by weight, 3 parts by weight of ma...

Embodiment 2

[0053] The method for making brick powder concrete by using waste sintered shale brick powder comprises the following steps:

[0054] (1) Recycling waste sintered shale bricks, using manual hammering, preliminary crushing, and sorting to remove impurities from waste sintered shale bricks;

[0055] (2) Use a jaw crusher to crush the waste sintered shale bricks after removal of impurities, and dry them after crushing;

[0056] (3) Finely grind the broken waste sintered shale bricks, sieve with a vibrating sieve machine, and dry them in an oven to obtain waste sintered shale brick powder. The fineness of the waste sintered shale brick powder is 0.10 mm;

[0057] (4) In terms of parts by weight, the raw materials used are as follows: 400 parts by weight of cement, 610 parts by weight of medium sand, 1135 parts by weight of stones with a particle size of 20mm, 200 parts by weight of water, 48 parts by weight of waste sintered shale brick powder Part, 4 parts by weight of magnesiu...

Embodiment 3

[0062] The method for making brick powder concrete by using waste sintered shale brick powder is characterized in that it comprises the following steps:

[0063] (1) Recycling waste sintered shale bricks, using manual hammering, preliminary crushing, and sorting to remove impurities from waste sintered shale bricks;

[0064] (2) Use a jaw crusher to crush the waste sintered shale bricks after removal of impurities, and dry them after crushing;

[0065] (3) Finely grind the broken waste sintered shale bricks, sieve with a vibrating sieve machine, and dry them in an oven to obtain waste sintered shale brick powder. The fineness of the waste sintered shale brick powder is 0.15 mm;

[0066] (4) In parts by weight, the raw materials used are as follows: 445 parts by weight of cement, 620 parts by weight of medium sand, 1185 parts by weight of stones with a particle size of 22mm, 210 parts by weight of water, 96 parts by weight of waste sintered shale brick powder Part, 5 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com