Method for recycling high-salt organic wastewater

An organic wastewater and high-salt technology, which is applied in the field of high-salt organic wastewater recycling and high-salt organic wastewater recycling, can solve problems such as low efficiency of hydrogen peroxide oxidation, and achieve the improvement of oxidation reaction efficiency and reaction efficiency. The effect of speed increase and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

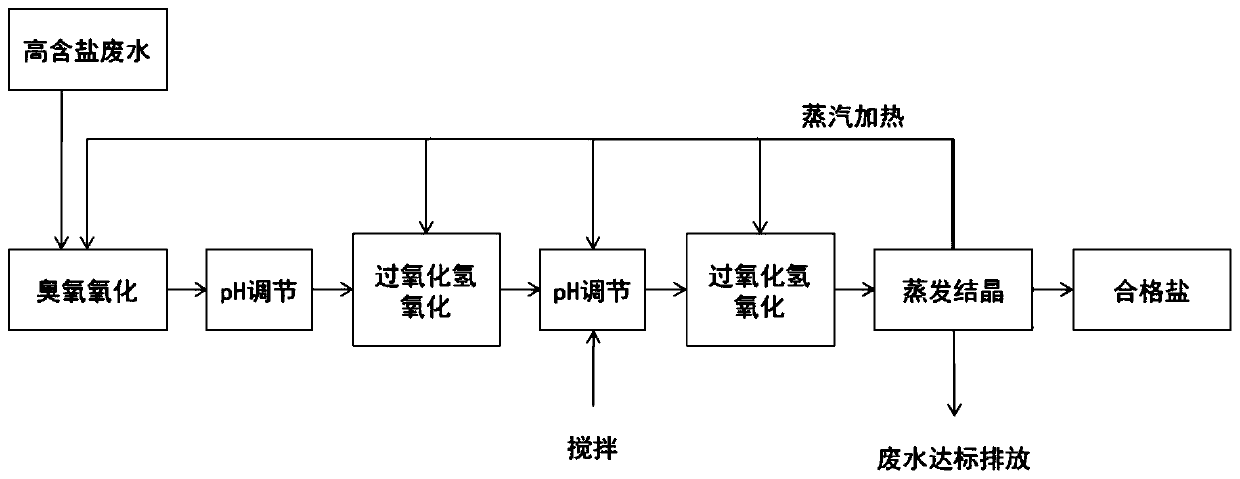

[0034] Such as figure 1 As shown, a salt-containing organic wastewater of a chemical factory producing ethers in Jiangsu is selected, and the factory produces about 50,000 tons of sodium chloride-containing organic wastewater every year. After detection and analysis, the salt content of the wastewater was 16%, the pH of the wastewater was 11.2, and the organic matter content in the wastewater was 897mg / L in terms of COD;

[0035] In the first step, the wastewater directly enters the ozone oxidation, and according to the organic matter content of the wastewater in terms of COD, the mass concentration of O 3 : COD is 1:1 ozone amount, use steam to heat the pre-ozonation process to 50°C, after 2 hours of ozone oxidation, the pH of wastewater will drop to 6.8-7.0, and the COD will drop to 625mg / L.

[0036] In the second step, the wastewater enters the hydrogen peroxide oxidation, and the mass concentration of H 2 o 2 : COD is 5:1, under 200rpm stirring condition, steam heating ...

Embodiment 2

[0057] A salt-containing organic wastewater from a chemical plant producing 2-4D acid in Jiangsu was selected. The plant produces about 20,000 tons of sodium chloride-containing organic wastewater every year. After detection and analysis, the salt content of the wastewater is 21%, the pH of the wastewater is 6.84, and the organic matter content in the wastewater is 2525mg / L in terms of COD.

[0058] Wastewater enters into ozone oxidation, according to the organic matter content of the waste water, the amount of COD is added, and the mass concentration of O 3 :COD is 1.5:1 ozone amount, the ozone oxidation process is heated by steam to 60°C, after 1.5h of ozone oxidation, the pH of the wastewater is reduced to 4.36, and the COD is reduced to 1462mg / L.

[0059] Adjust the pH of the wastewater to 6.5-6.7, carry out hydrogen peroxide oxidation, and add mass concentration H 2 o 2 : COD is 1:1, under the condition of 300rpm stirring, steam heating temperature to 60 ℃ for 2h, COD d...

Embodiment 3

[0064] The salt-containing organic wastewater of a pharmaceutical intermediate enterprise in Jiangsu was selected. The factory produces about 10,000 tons of potassium chloride-containing organic wastewater every year. After detection and analysis, the salt content of the wastewater is 8%, the pH of the wastewater is 3.2, and the organic matter content in the wastewater is 4386 mg / L in terms of COD.

[0065] Wastewater enters into ozone oxidation, according to the organic matter content of the waste water, the amount of COD is added, and the mass concentration of O 3 : COD is 2:1 ozone amount, use steam to heat the ozone oxidation process to 40°C, after 0.5h of ozone oxidation, the pH of the wastewater becomes 3.9, and the COD drops to 2462mg / L.

[0066] Adjust the pH of the wastewater to 6.6-6.7, carry out hydrogen peroxide oxidation, and add mass concentration H 2 o 2 : COD is 2:1, under the condition of 250rpm stirring, steam heating temperature to 80 ℃ for 1h, COD drops t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com