Silicon steel roll leveling machine coating system and leveling machine

A technology of leveling machine and film coating, which is applied in the field of silicon steel coil processing, can solve the problems of insufficient precision and low degree of automation of film coating, and achieve the effects of high precision, good consistency, guaranteed precision and good product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

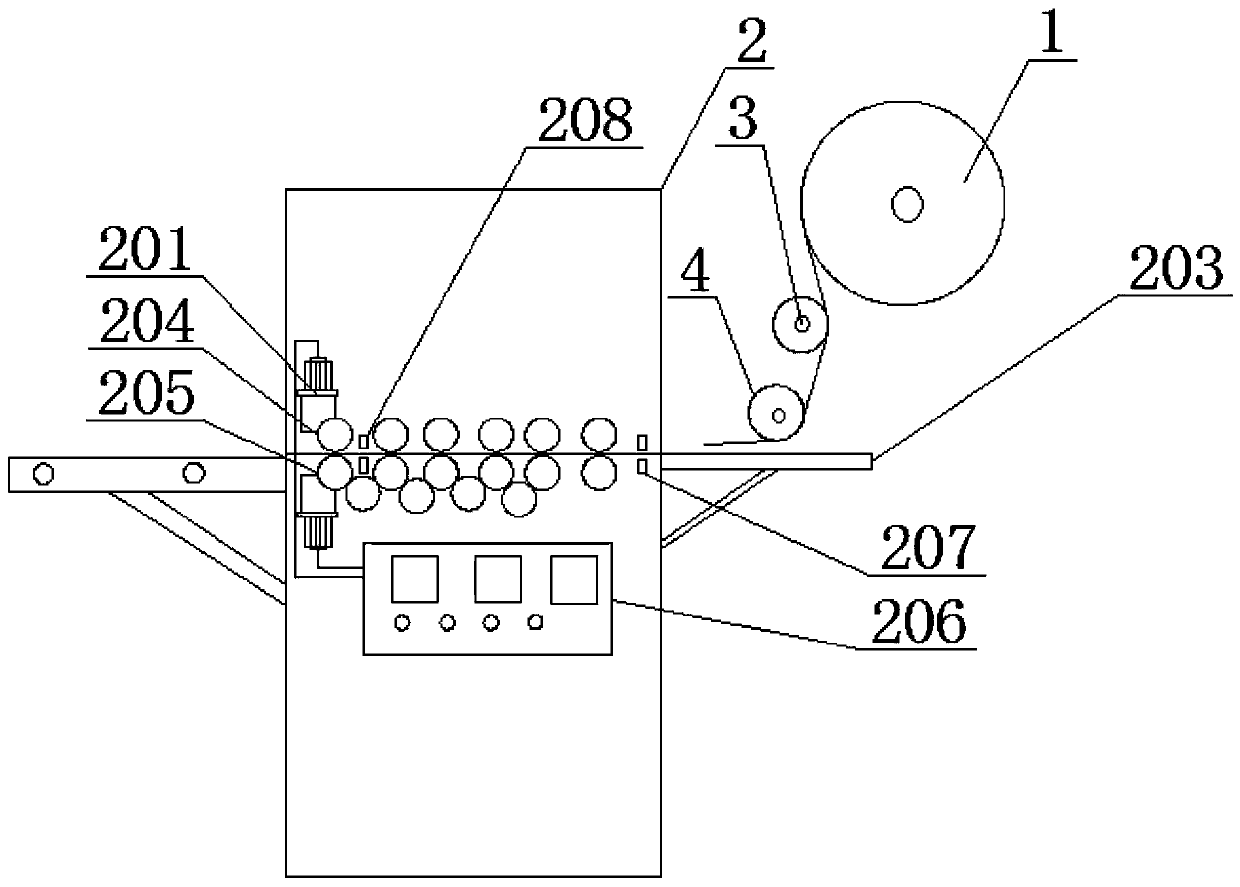

[0029] Such as figure 1 As shown, a coating system of a silicon steel coil leveling machine in this scheme includes a leveling machine 2, and a laminating roller 4 is arranged on the upper part of the inlet pallet 203 of the leveling machine 2, and the laminating roller 4 is provided with tensioning Roller 3 and film roll 1, lamination roll 4, tension roll 3 and film roll 1 are respectively connected to the frame on both sides of leveler 2, and both ends have corresponding shafts connected to the frame respectively, corresponding to each other. The laminating roller 4 is supported by the supports on both sides of the inlet pallet 203 , and the supports control the rising and falling of the laminating roller 4 .

[0030] The tension roller 3 is arranged between the pressure film roller 4 and the film roll 1, and the frame connection position between the tension roller 3 and the leveling machine 2 is provided with a moving track, and is driven by a driving device, and the corres...

Embodiment 2

[0032] A leveling machine of a steel coil leveling machine coating system, including a frame, an inlet pallet 203, an upper leveling roller 204 and a lower leveling roller 205, and an upper leveling roller motor 201 and a lower leveling roller motor 202, the The upper leveling roller motor 201 and the lower leveling roller motor 202 are respectively connected to the upper leveling roller 204 and the lower leveling roller 205, and the feeding end between the upper leveling roller motor 201 and the lower leveling roller motor 202 is equipped with a feeder for measuring the feed gap The inlet roller detector 207, the area before the last upper leveling roller 204 and the lower leveling roller 205 at the feeding end between the upper leveling leveling roller motor 201 and the lower leveling leveling roller motor 202 is installed with a sensor for measuring the discharge gap The exit roller detector 208, the upper leveling roller motor 201 and the lower leveling roller motor 202 are...

Embodiment 3

[0036] The laminating method and leveling method of the corresponding leveling machine are as follows:

[0037] Since the steel coil entering the leveling machine may sometimes be inclined or bent up and down, unevenness or wrinkles may occur when laminating at this time. The two ends of the lamination roller 4 of this solution are also provided with calibration brackets. The end of the calibration bracket is provided with a drive motor, which can adjust the height of the support rod, and the two ends of the support rod are connected to the two ends of the lamination roller 4, and the drive motor drives the lamination roller 4 to move in a direction perpendicular to the film movement. When the roll is tilted, especially when it is perpendicular to the direction of film movement, the lamination roller 4 will move in a direction perpendicular to the film movement. Since the lamination roller 4 is pressed against the film, it will drive the film to a certain degree. The inclinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com