A double-shaft cantilever skew rolling mill

A technology of cantilever type and skew rolling mill, which is applied in the direction of cantilever type rolling mill stand, metal rolling stand, metal rolling mill stand, etc. It can solve the problems of complex installation and adjustment steps, single production product, and cumbersome roll changing steps, etc., and achieve The effect of shortening the roll changing time, long action line and small position fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with specific drawings. It should be noted that the technical features or combinations of technical features described in the following embodiments should not be regarded as isolated, and they can be combined with each other to achieve better technical effects.

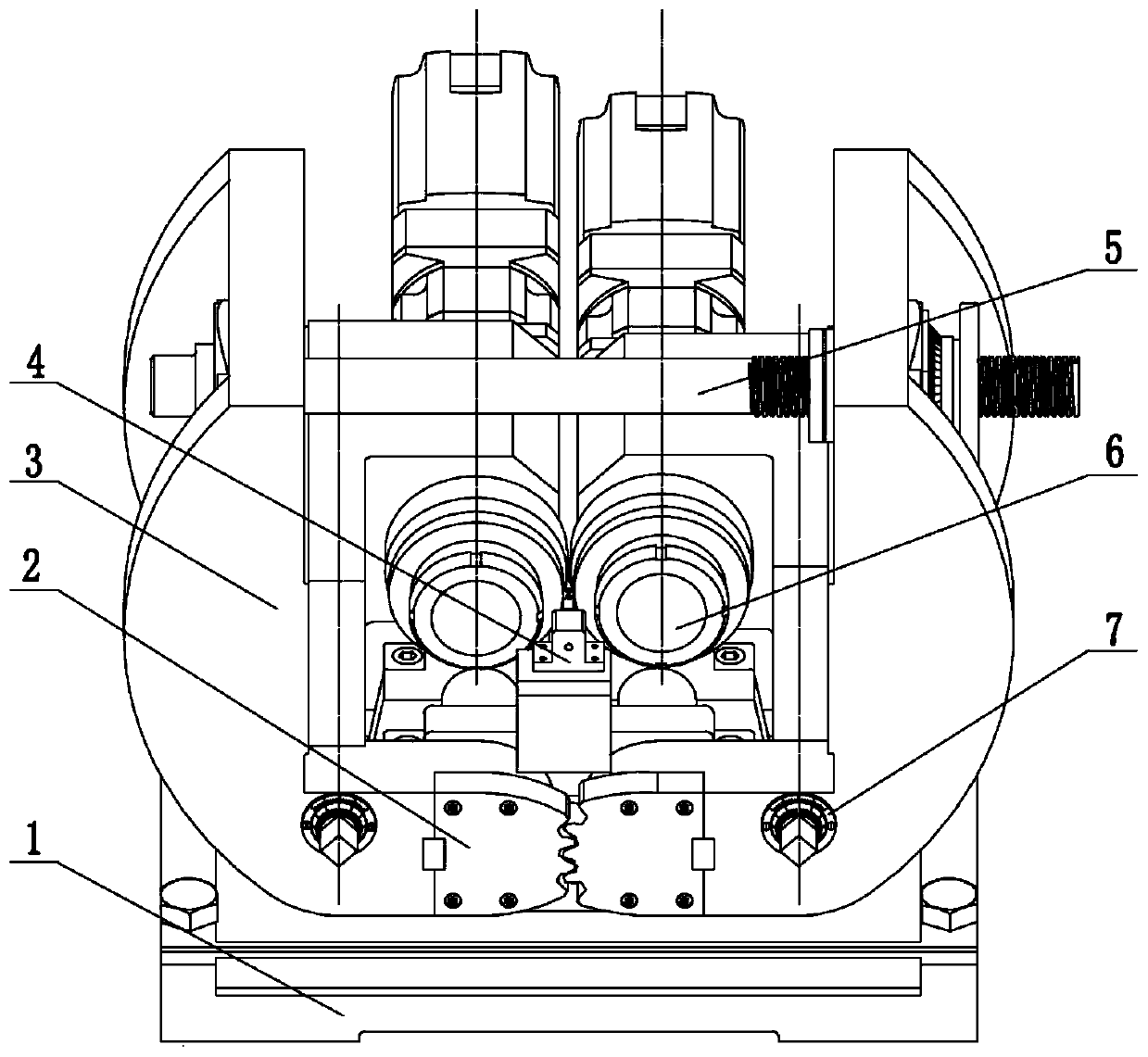

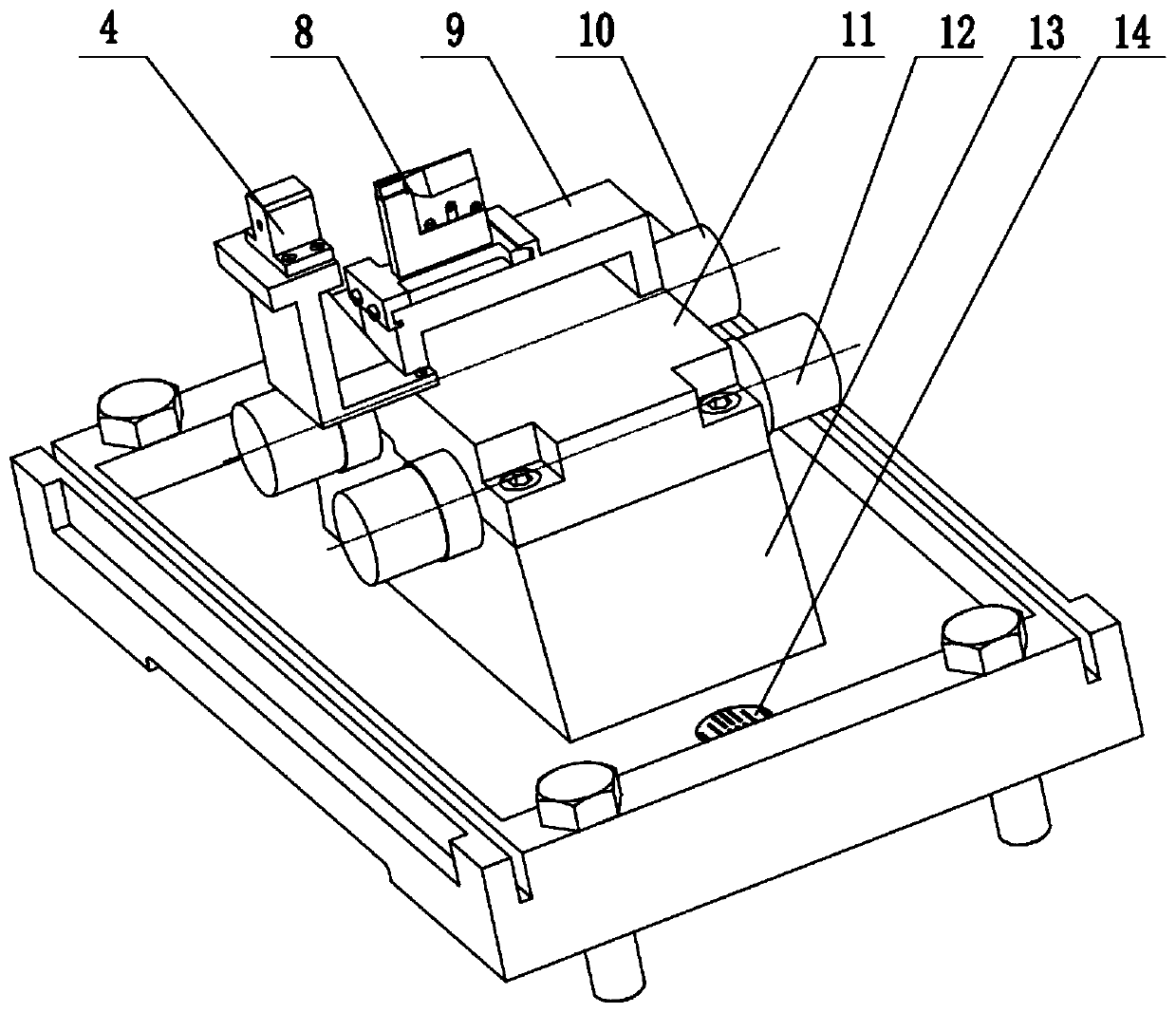

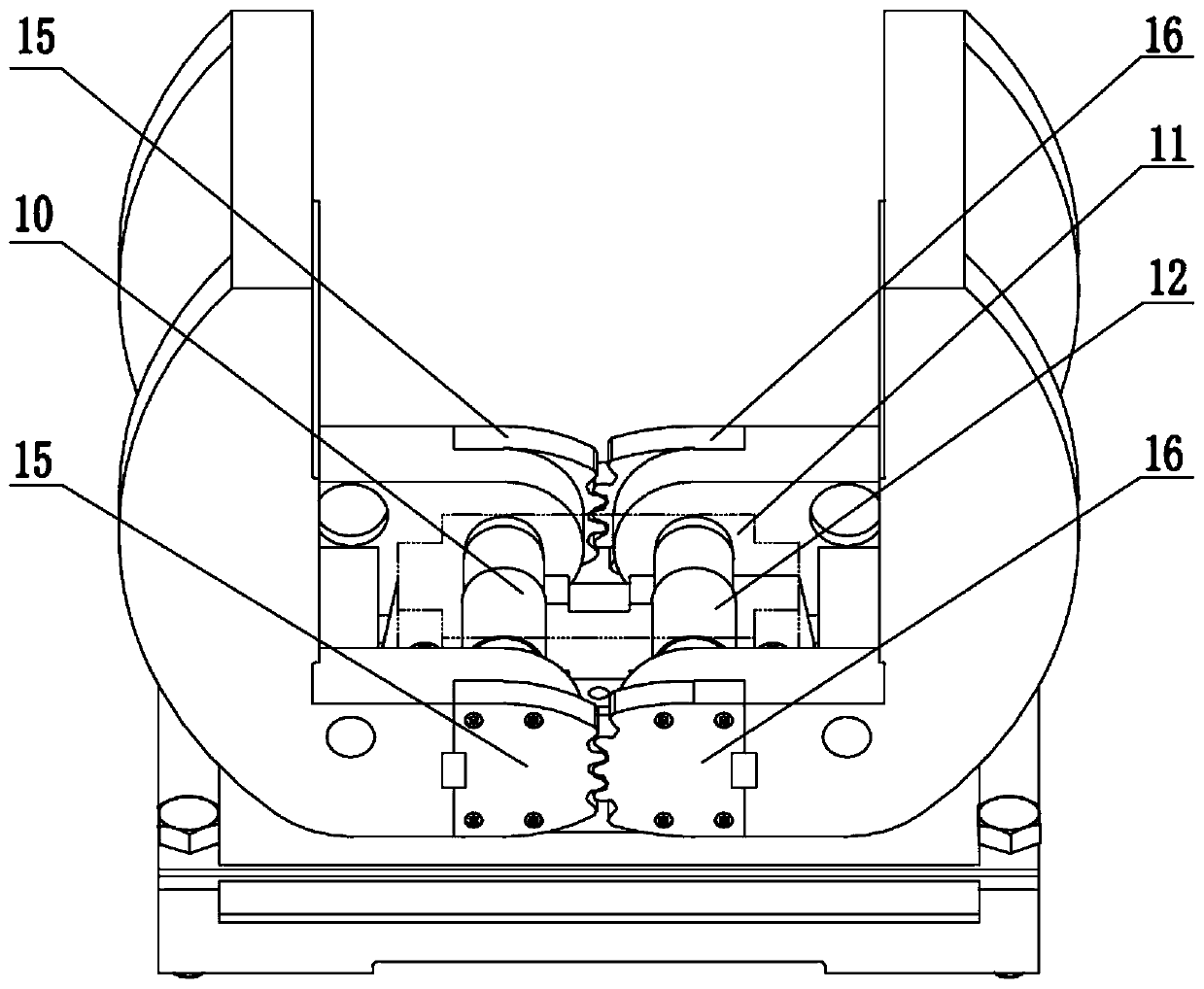

[0044] Such as Figure 1-7 As shown, the embodiment of the present invention is a double-shaft cantilever skew rolling mill, including a base unit, a material guide unit, a frame unit (left frame, right frame), a gear synchronization mechanism (left gear, right gear), a cantilever type Roller system (left roller system, right roller system), radial pressing mechanism, tilt angle adjustment mechanism (left tilt angle adjustment mechanism, right tilt angle adjustment mechanism);

[0045] Such as figure 1 , figure 2 As shown, the double shaft cantilever skew rolling mill is installed on the base unit through the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com