A method for controlled rolling of medium-sized bars

A technology for controlling rolling and specifications, applied in the field of uniform cooling of intermediate billets in a rotary cooling mechanism, can solve the problems of uneven surface cooling of intermediate billets, complex structure, inability to achieve rapid and uniform temperature drop of intermediate billets, etc. The effect of length, compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

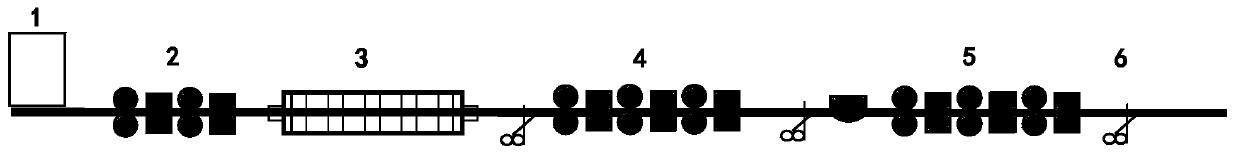

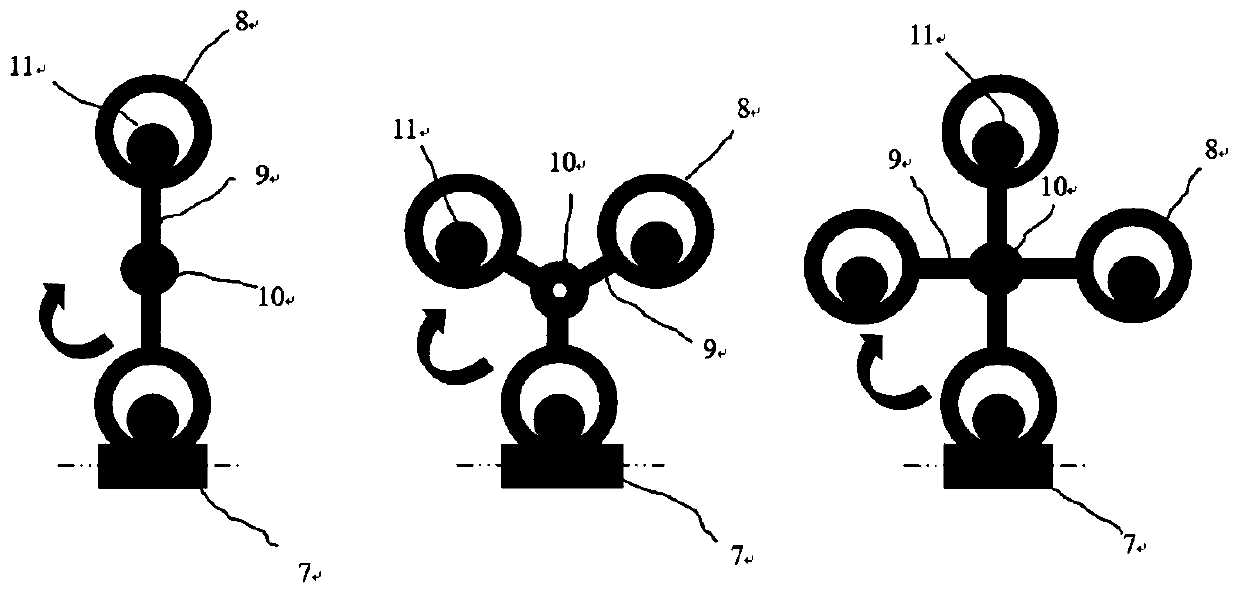

[0036] The finished product is The medium-sized bar, the billet heated by the heating furnace is rolled by the rough rolling unit, and then transported to the roller table 7 of the rolling line, and then The intermediate blank enters the ring frame 8 of the rotary cooling mechanism. The starting position of the lower edge of the inner diameter of the ring frame 8 is slightly lower than the roller surface level of the rolling line roller table 7, so as to ensure that the intermediate blank enters the ring frame 8 completely. After waiting for the rotary cooling mechanism to be lifted upwards, take the direction perpendicular to the coming direction of the intermediate billet 11 as the reference plane, and start to rotate clockwise around the central axis 10 of the rotary cooling mechanism. Before the arrival of the second intermediate blank, it is necessary to ensure that the descending height of the lower edge of the hollow ring frame 8 inner diameter is slightly lower than...

Embodiment 2

[0039] The finished product is medium gauge rods. After the billet is heated out of the furnace, the phosphorus is removed by high-pressure water, and then enters the rough rolling unit and the intermediate rolling unit. The intermediate blank enters the ring frame 8 of the rotary cooling mechanism, and the starting position of the lower edge of the inner diameter of the ring frame 8 is slightly lower than the roller surface level of the rolling line roller table 7 to ensure that the intermediate blank 11 enters the ring frame 8 completely. After waiting for the rotary cooling mechanism to be lifted up, take the direction perpendicular to the arrival of the intermediate billet 11 as the reference plane, and start to rotate clockwise around the central axis 10 of the rotary cooling mechanism. Before the arrival of the second intermediate blank, it is necessary to ensure that the descending height of the lower edge of the hollow ring frame 8 inner diameter is slightly lower th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com