Permanent magnet rotor

A technology of permanent magnets and rotors, applied in the field of rotors, can solve the problems of reduced yield, increased production cost, and impact on yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

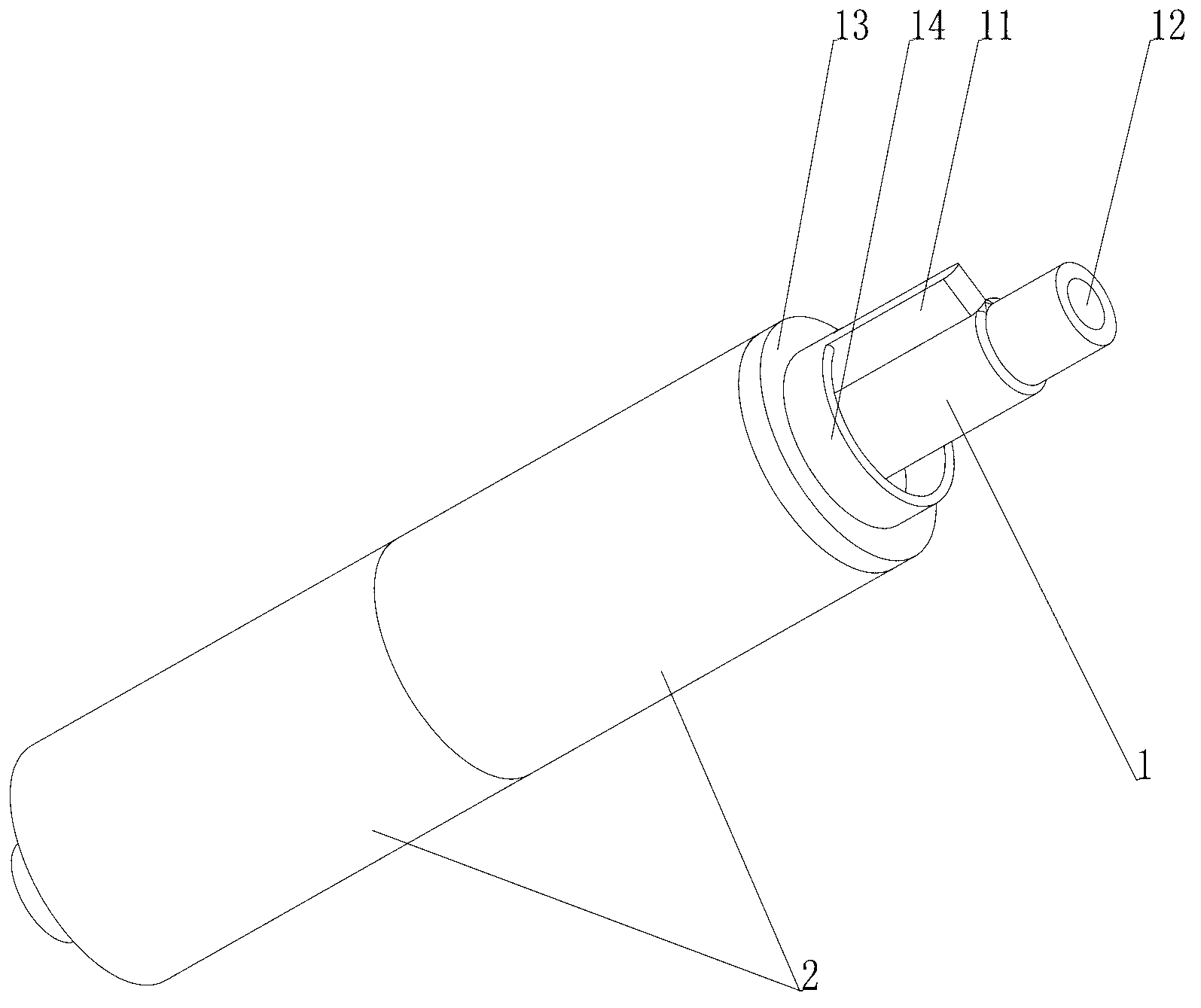

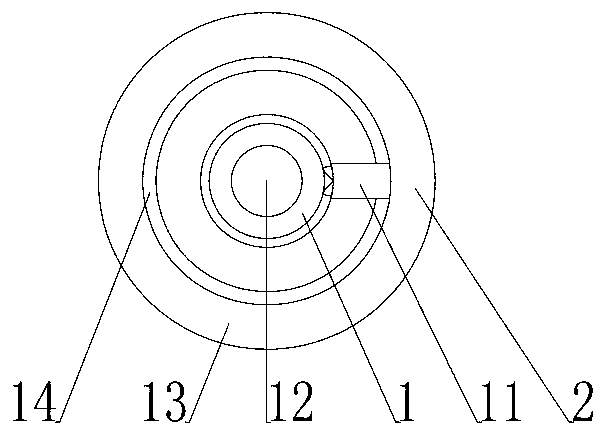

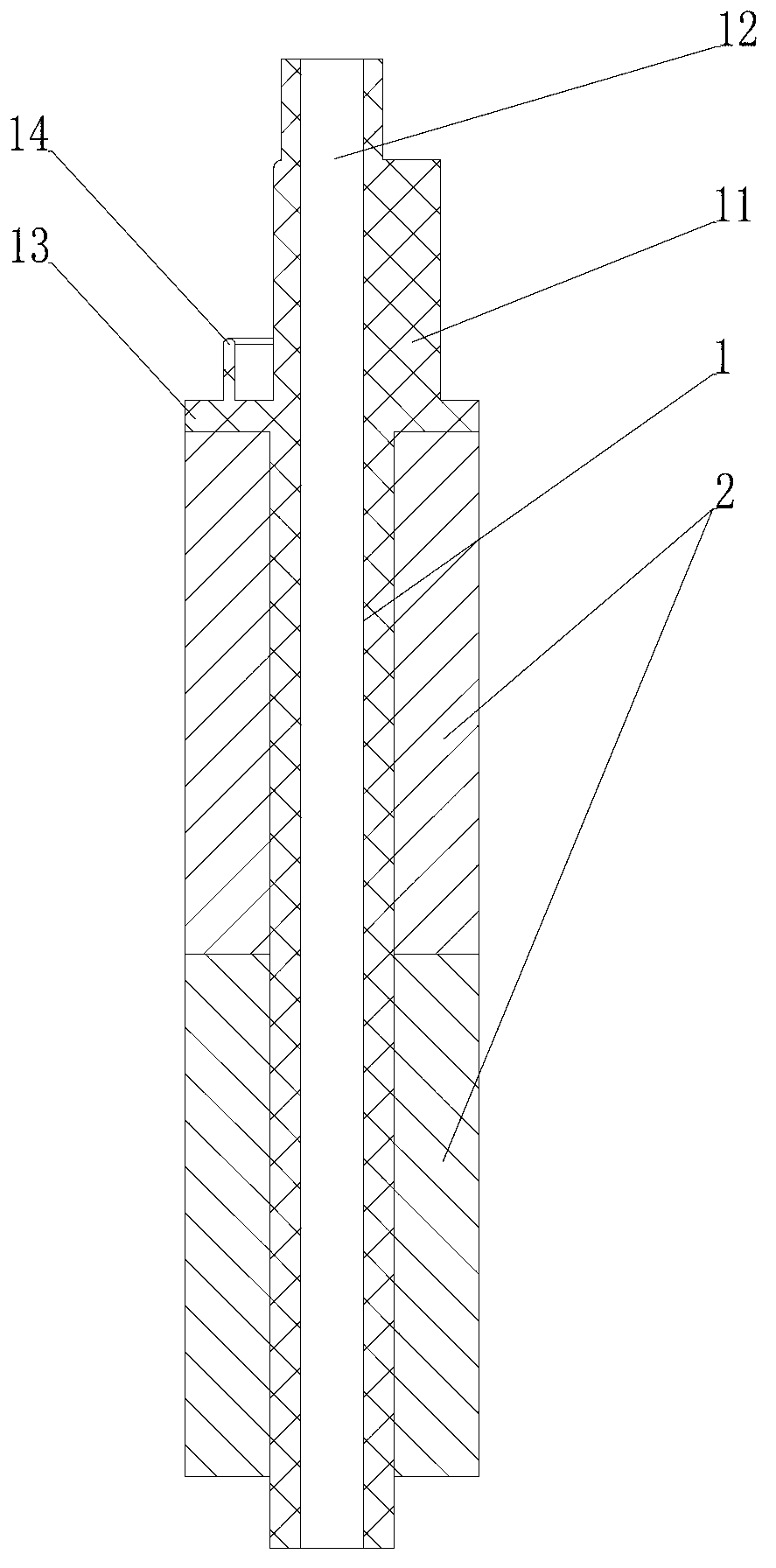

[0014] Such as figure 1 The rotor shown includes several cylindrical magnets 2 connected head to tail, a central hole is provided at the center of the magnets 2, and a rotating shaft 1 is arranged in the central hole of the magnets 2 to connect and fix each magnet 2 in series. The same magnetic poles on the magnets 2 are kept on the same side, and the fixing of the rotating shaft 1 can ensure that the magnetic repulsion between the magnets 2 will not cause the magnets to disengage or rotate. At least one end of the rotating shaft 1 protrudes from the magnet 2 and is placed outside as a transmission shaft for connecting external devices. There is also a rotating key 11 at the end of the rotating shaft 1 placed outside the magnet 2, and a stopper is also provided on the rotating shaft 1 at the end of the rotating key 11. 13. The baffle 13 seals one end of the magnet. The baffle 13 is also provided with a ring-shaped rib 14 which can act as a buffer. There is also a through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com