Laying method convenient for position exchange of cable line in electric power cabin

A technology of cable line and position exchange, applied in the direction of cable laying equipment, etc., can solve the problems of irregular laying method and endanger the safe operation of cable line, etc., and achieve the effect of saving project cost, simple construction process and tight clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention discloses a laying method for conveniently changing the position of the cable line in the electric cabin, comprising the following steps,

[0028] Step 1) Install the cable support frame 2 in the power cabin 1, and the support frame 2 is set in multiple rows and columns;

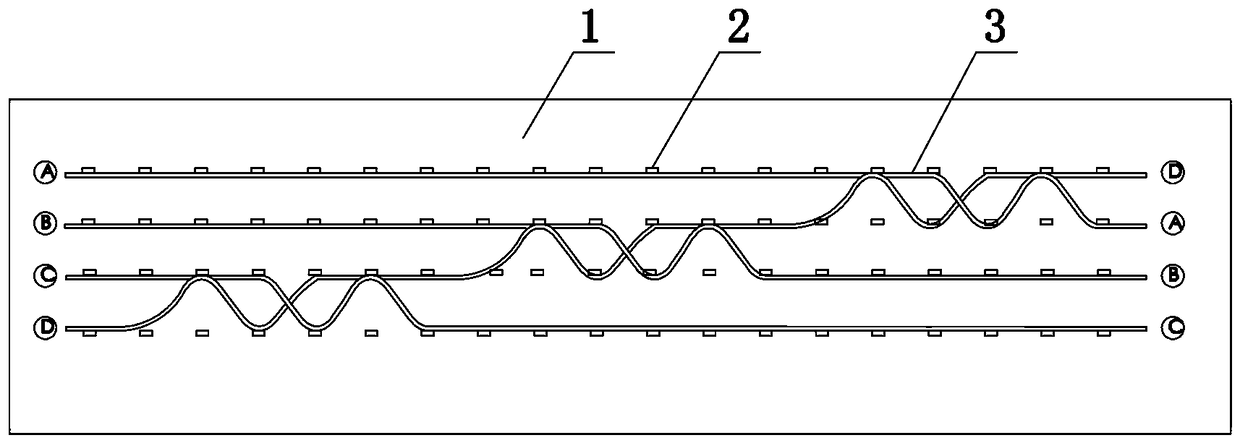

[0029] Step 2) Lay multiple cables 3 (four shown in the figure) in a spiral manner and fix them on the support frame 2. The spiral directions of two adjacent cables 3 are the same, and the positions of the spirals are misplaced (such as figure 1 shown).

[0030] figure 1 Taking the four cables arranged vertically as an example, the purpose is to realize the right top outlet of the bottom circuit (the right end of the D-number cable at the bottom of the power cabin is routed from the top of the power cabin), and the method of three times of spiral transposition from left to right is adopted: The first time is to transpose the screw of D cable and C cable (a single cable can be turned up...

Embodiment 2

[0032] The invention discloses a laying method for conveniently changing the position of the cable line in the electric cabin, comprising the following steps,

[0033] Step 1) Install the cable support frame 2 in the power cabin 1, and the support frame 2 is set in multiple rows and columns;

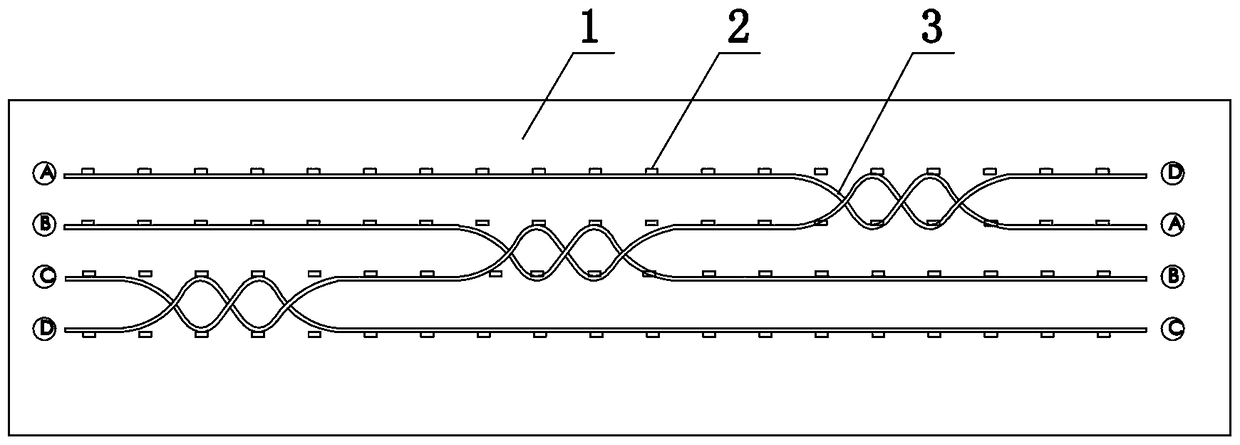

[0034] Step 2) Lay several cables 3 (four shown in the figure) in a spiral manner and fix them on the support frame 2. The spiral sections of multiple cables 3 do not touch each other, and the spiral direction of two adjacent cables 3 on the contrary.

[0035] figure 2 Take the four cables arranged vertically as an example. The purpose is to realize the right top outlet of the bottom circuit (the right end of the D-number cable at the bottom of the power cabin is routed from the top of the power cabin), and the method of three-time spiral transposition from left to right is adopted. : The first time is to transpose the screw of D cable and C cable (a single cable can be turned up by s...

Embodiment 3

[0038] The present invention is a kind of laying method that is convenient for changing the position of the cable line in the electric cabin, comprising the following steps,

[0039] Step 1) Install the cable support frame 2 in the power cabin 1, and the support frame 2 is set in multiple rows and columns;

[0040] Step 2) Lay several cables 3 (four shown in the figure) in a spiral manner and fix them on the support frame 2. The spiral sections of multiple cables 3 do not touch each other, and the spiral direction of two adjacent cables 3 on the contrary.

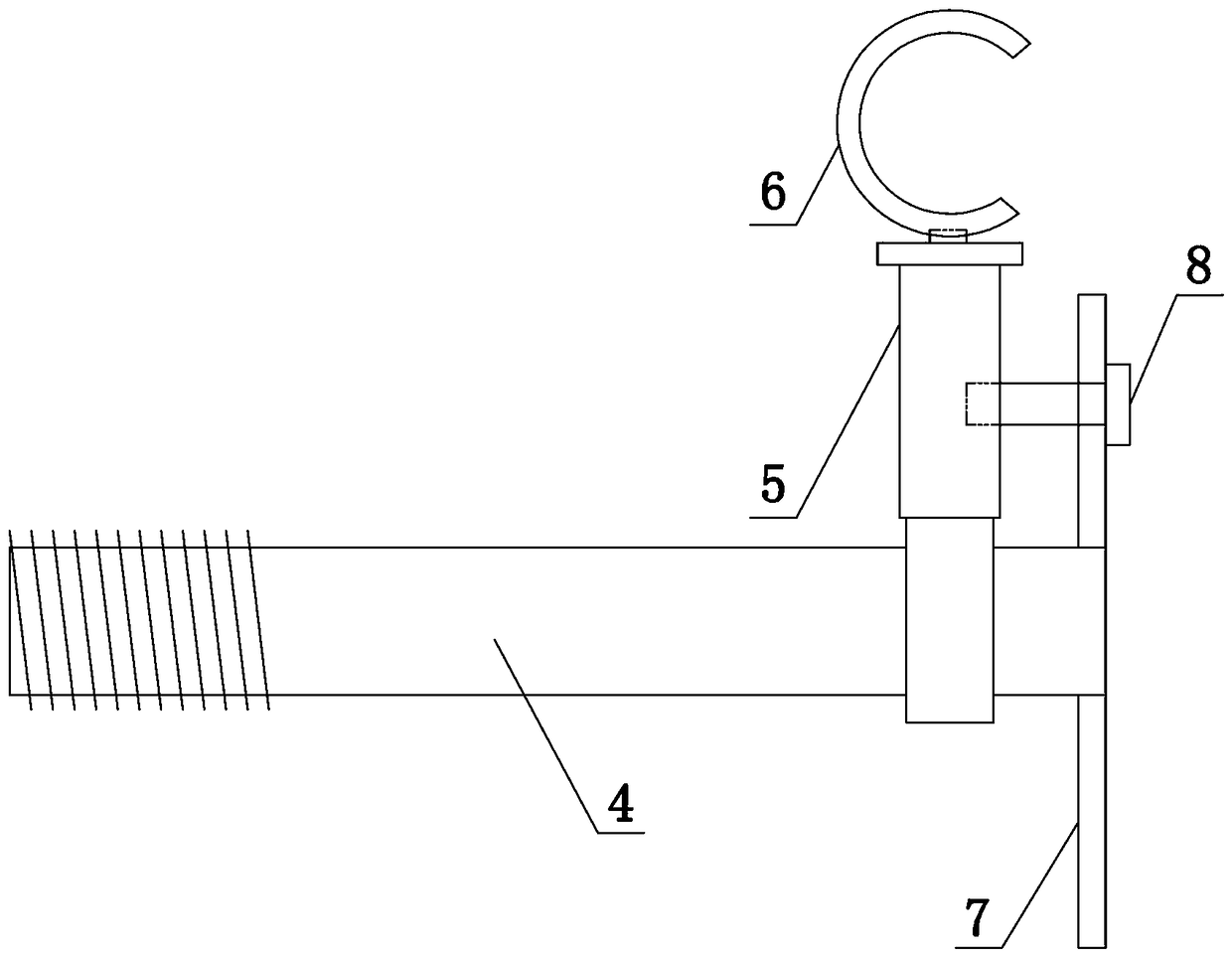

[0041] like Figure 4 As shown, the support frame 2 includes a support rod 4, one end of the support rod 4 is provided with an external thread, and is fixed on the bulkhead of the power cabin 1 by an expansion screw, and the other end of the support rod 4 is provided with a support mechanism, and the support mechanism is designed to be two up and down. The supporting mechanism includes a connecting rod 5 and a C-shaped ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com