Grease composition and preparing method thereof

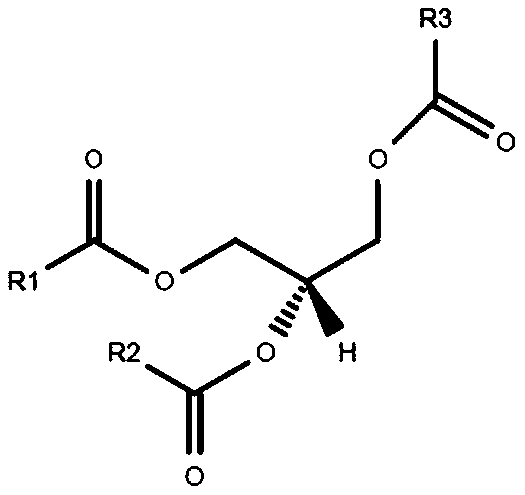

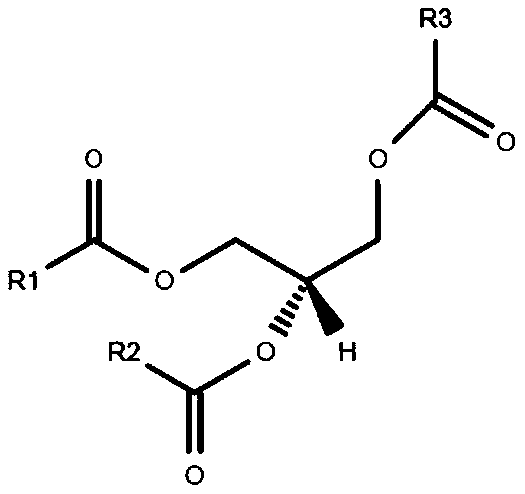

An oil composition and composition technology, applied in the field of oil compositions rich in unsaturated fatty acids and short- and medium-chain fatty acids, can solve the problems of low PUFA digestion and absorption rate and low physiological availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

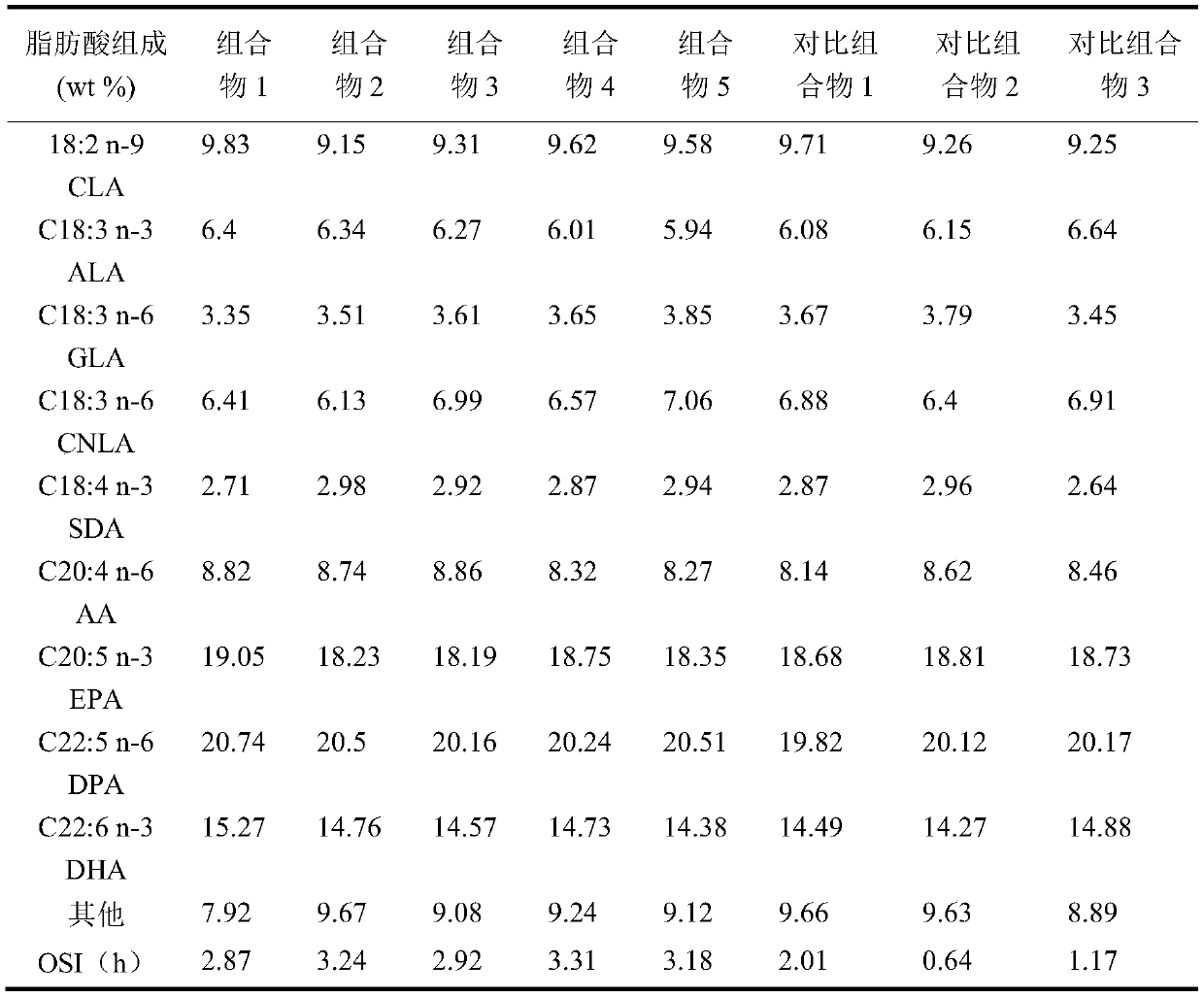

Embodiment 1

[0023] Commercially available high-purity EPA, DHA, DPA, AA, SDA, ALA, GLA, CNLA and CLA polyunsaturated fatty acids are used as raw materials and mixed in a certain proportion (EPA 18.60%, DHA 14.67%, DPA20.25%, AA8. 53%, SDA2.71%, ALA6.23%, GLA3.61%, CNLA 6.67% and CLA 9.46%, other fatty acids 9.24%). The mixed fatty acid and glycerol triacetate are mixed according to the molar ratio of 2.5:1, the immobilized lipase LipozymeRM (Novozymes company product) of 5% of the mass of the mixture is added, and they are placed in a constant temperature stirring reactor at 50-60°C together. The absolute pressure is below 200Pa, and the reaction time is 8h. After the oil phase of the reactant is recovered, it is separated and purified by molecular distillation. The molecular distillation temperature is 180-190°C, and the working absolute pressure of the molecular still is below 1Pa. Free fatty acids and other low boiling point components are removed to obtain polyunsaturated fatty acids ...

Embodiment 2

[0025] Commercially available high-purity EPA, DHA, DPA, AA, SDA, ALA, GLA, CNLA and CLA polyunsaturated fatty acids are used as raw materials, mixed in a certain proportion (EPA 18.60%, DHA 14.67%, DPA 20.25%, AA 8.53% , SDA 2.71%, ALA 6.23%, GLA 3.61%, CNLA 6.67% and CLA 9.46%, other fatty acids 9.24%). The mixed fatty acid and tributyrin are mixed according to the molar ratio of 2.5:1, the immobilized lipase LipozymeRM (product of Novozymes) with 5% of the mass of the mixture is added, and they are placed together in a constant temperature stirring reactor at 50-60°C, and the reaction The absolute pressure of the device is below 200Pa, and the reaction time is 8h. After the oil phase of the reactant is recovered, it is separated and purified by molecular distillation. The molecular distillation temperature is 180-190°C, and the working absolute pressure of the molecular still is below 1Pa. Free fatty acids and other low boiling point components are removed to obtain polyuns...

Embodiment 3

[0027]Commercially available high-purity EPA, DHA, DPA, AA, SDA, ALA, GLA, CNLA and CLA polyunsaturated fatty acids are used as raw materials, mixed in a certain proportion (EPA 18.60%, DHA 14.67%, DPA 20.25%, AA 8.53% , SDA 2.71%, ALA 6.23%, GLA 3.61%, CNLA 6.67% and CLA 9.46%, other fatty acids 9.24%). The mixed fatty acid and tricaproic acid glyceride are mixed according to the molar ratio of 2.5:1, the immobilized lipase LipozymeRM (Novozymes company product) of 5% of the mass of the mixture is added, and they are placed together in a constant temperature stirring reactor at 50-60°C, and the reaction The absolute pressure of the device is below 100Pa, and the reaction time is 12h. After the oil phase of the reactant is recovered, it is separated and purified by molecular distillation. The molecular distillation temperature is 180-190°C, and the working absolute pressure of the molecular still is below 1Pa. Free fatty acids and other low boiling point components are removed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com