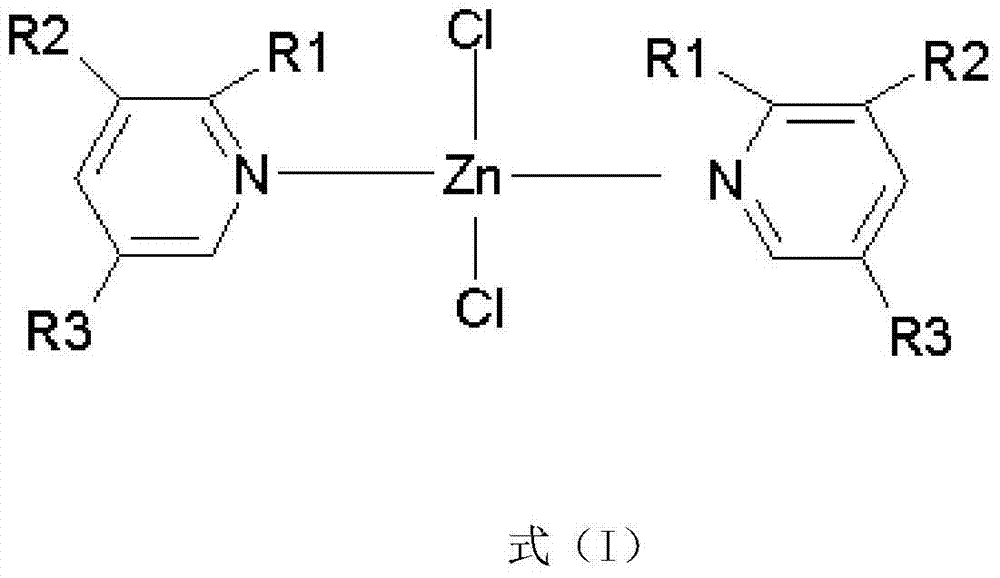

Application of pyridine zinc complex in tobacco product

A technology of tobacco products and complexes, applied in the field of tobacco, which can solve the problems of high volatility, outstanding smell, easy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

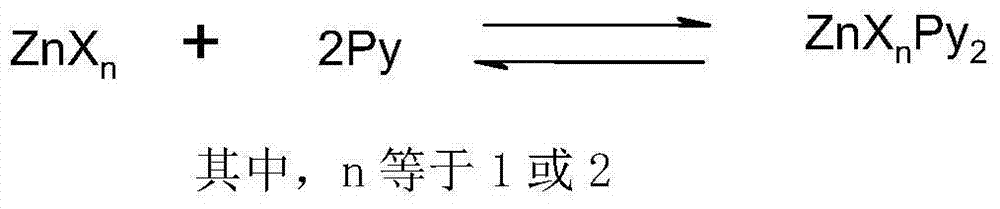

Method used

Image

Examples

Embodiment 1

[0019] Weigh a certain amount of complex ZnCl 2 (lut) 2 , ZnCl 2 (etpy) 2 , ZnCl 2 (acpy) 2 , dissolved in ethanol after mixing, applied to the cigarette part of heat-not-burn tobacco (or reconstituted tobacco substrate or reconstituted tobacco), the application ratio of the three complexes is 0.01% of the tobacco weight. Put it into a constant temperature drying oven to balance for 24 hours . Heated to 180°C with the heating chamber for HNB tobacco, collected the flue gas with a hand-held gas sampler, and measured the chemical composition of the flue gas with a headspace GC-MS instrument. It was found that there were 3-ethylpyridine, 3,5- Lutidine, 3-acetylpyridine three aroma substances.

[0020] After the above-mentioned heat-not-burn tobacco is made, the heat-not-burn tobacco is inhaled in a non-heated state, and the gas inhaled into the mouth does not show the characteristic smell of 3-acetylpyridine, 3-ethylpyridine and 3,5-lutidine. Fragrance and bitterness; but ...

Embodiment 2

[0022] The spice 3,5-lutidine and the complex ZnCl 2 (lut) 2 Dissolved in ethanol, respectively applied to the cigarette part of the heat-not-burn tobacco (reconstituted tobacco), the dosage is 1 / 10,000 of the weight of the reconstituted tobacco, and respectively made into experimental sample and control sample heat-not-burn tobacco. Heated to 180 ℃ with the heating chamber of HNB tobacco, and smoked the smoke at the same time. It was found that the smoke of the experimental sample with the complex could experience the unique aroma of pyridine substances, and it was relatively uniform; while the flavor was applied For the control sample of 3,5-lutidine, the aroma of pyridine substances in the first puff is very prominent and bitter, and the aroma characteristics of pyridine substances decrease sharply as the number of puffs increases.

Embodiment 3

[0024] Weigh a certain amount of complex ZnCl 2 (lut) 2 , ZnCl 2 (etpy) 2 , ZnCl 2 (acpy) 2 , dissolved in ethanol after mixing, applied to shredded tobacco, the application ratio of the three complexes is 0.5% of the tobacco weight, smoked on a smoking machine after being made into cigarettes, and the total particulate matter on the Cambridge filter is extracted with ethanol, and the GC-MS The chromatograms measured by the instrument. It can be seen that the three complexes are cracked when the cigarette is smoked, and three aroma substances, 3-ethylpyridine, 3,5-lutidine and 3-acetylpyridine, are released to the particulate phase of the smoke.

[0025] After the above-mentioned cigarettes are made, smell and distinguish the smell of cigarettes, and the smell of cigarettes does not reflect the unique smell of 3-acetylpyridine, 3-ethylpyridine and 3,5-lutidine; but if 3-acetylpyridine , 3-ethylpyridine and 3,5-lutidine instead of the above-mentioned complexes, the smell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com