A kind of production technology of highly compound cooking wine

A production process and composite material technology, which is applied in the field of food processing, can solve the problems such as the effect of deodorization and aroma enhancement is not good enough, the flavor and taste are affected, and the dosage is difficult to control, so as to save energy, improve flavor and color, and tender The effect of sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

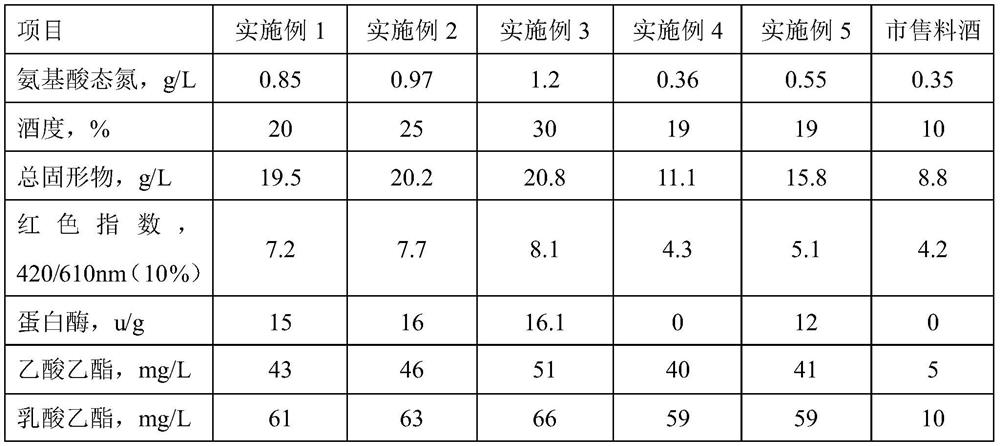

Examples

Embodiment 1

[0034] A kind of highly compound cooking wine production technology, comprises the following steps:

[0035] 1. Preparation of sorghum wine:

[0036] (A) Moisturizing: the sorghum is pressed into 4 petals with a roller press, and 50% of the normal temperature water is added by its weight to moisten the water for 10 hours and set aside;

[0037] (B) Cooking: the sorghum that has been moistened with water is put into a steamer and steamed under normal pressure for 3 hours, then taken out and cooled naturally to 45°C for later use;

[0038] (C) inoculation: add the rhizopus dako that crosses 60 mesh sieves through pulverizer by sorghum weight, and 1.8 times of aseptic water mix evenly for subsequent use;

[0039] (D) Fermentation: put into the fermenter for fermentation after receiving the seeds, the fermentation temperature is controlled at 25°C, the fermentation time is 20 days, and the alcohol content reaches 18% to obtain sorghum wine mash;

[0040] (E) Squeeze: the sorghum...

Embodiment 2

[0046] A kind of highly compound cooking wine production technology, comprises the following steps:

[0047] 1. Preparation of sorghum wine:

[0048] (A) Moisturizing: the sorghum is pressed into 5 petals with a roller press, and 55% of normal temperature water is added by its weight to moisten the water for 12 hours and set aside;

[0049] (B) Cooking: the sorghum that has been moistened with water is put into a steamer and steamed at normal pressure for 2.5 hours, then taken out and naturally cooled to 43°C for later use;

[0050] (C) inoculation: add the rhizopus dako that crosses 60 mesh sieves through pulverizer by sorghum weight, and 2 times of aseptic water mix evenly for subsequent use;

[0051] (D) Fermentation: put into the fermenter for fermentation after receiving the seeds, the fermentation temperature is controlled at 28°C, the fermentation time is 18 days, and the alcohol content reaches 17% to obtain sorghum wine mash;

[0052] (E) Squeeze: The sorghum wine m...

Embodiment 3

[0058] A kind of highly compound cooking wine production technology, comprises the following steps:

[0059] 1. Preparation of sorghum wine:

[0060] (A) Moisturizing: the sorghum is pressed into 6 petals with a roller press, and 60% of the normal temperature water is added by its weight to moisten the water for 14 hours and set aside;

[0061] (B) Cooking: put the sorghum moistened with water into a steamer and steam for 2 hours under normal pressure, then take it out and cool it down to 45°C for later use;

[0062] (C) inoculation: add the rhizopus dako that crosses 60 mesh sieves that pulverizes through pulverizer by sorghum weight, and 2.2 times of sterile water mix evenly for subsequent use;

[0063] (D) Fermentation: After picking the seeds, put them into a fermenter for fermentation, the fermentation temperature is controlled at 30°C, the fermentation time is 15 days, and the alcohol content reaches 16% to obtain sorghum wine mash;

[0064] (E) Squeeze: the sorghum wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com