Shallow buried weak-cementation top plate working face overlying strata zoning dividing method and application

A weak cementation and working face technology, applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as poor integrity, inability to guide on-site, and many applications of water-conducting fracture zones, and achieve accurate judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

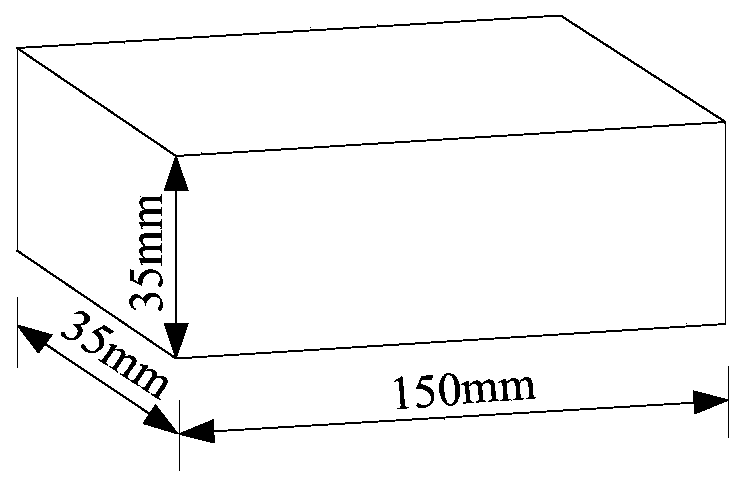

[0046] Step 1: Test piece preparation

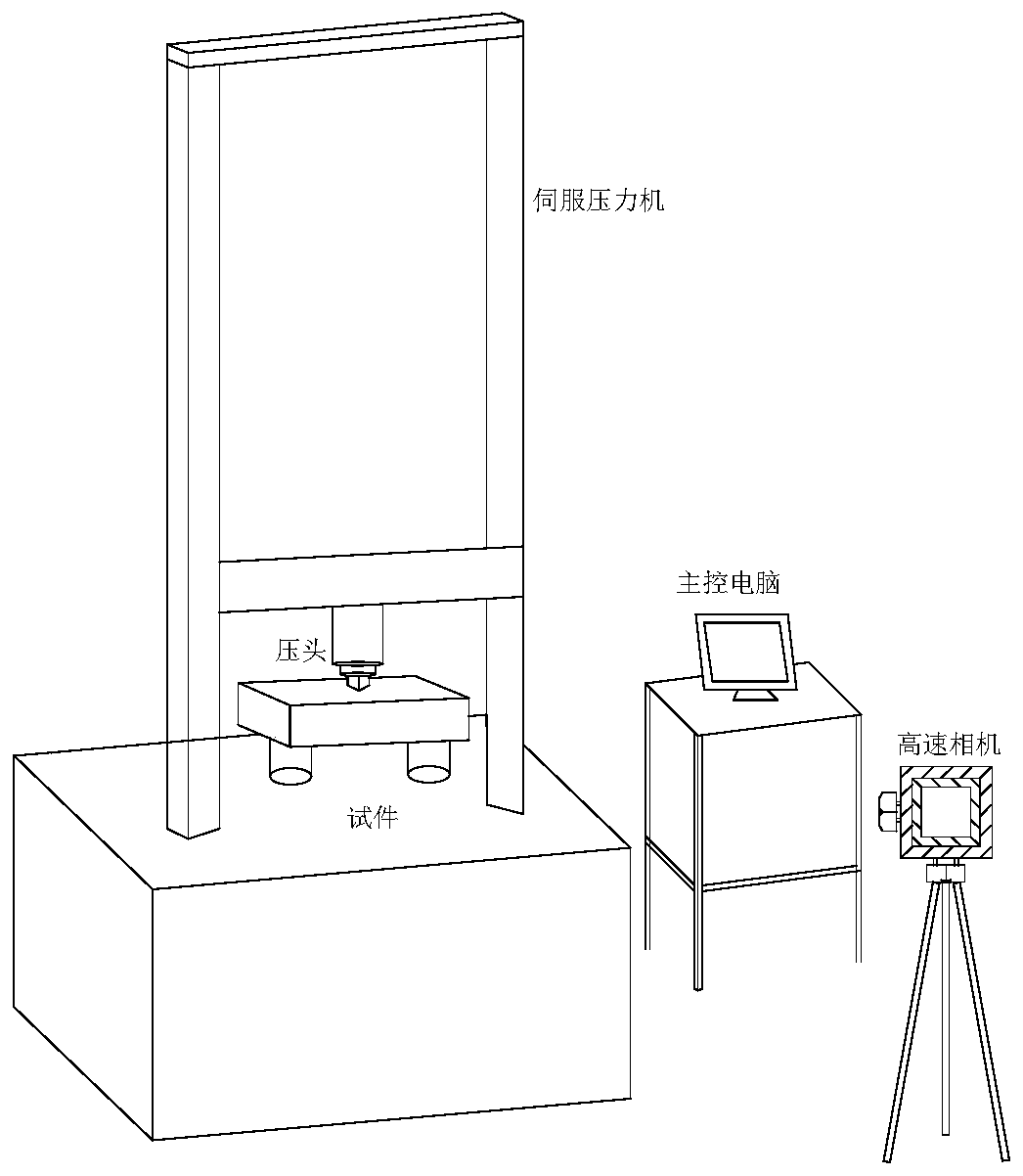

[0047] Obtain large pieces of weakly cemented sandy mudstone from the centralized roadway or working face of a typical shallow mine in the west, seal it with plastic wrap and transport it to the indoor laboratory; use a cutting machine to prepare the large piece of sandy mudstone into length × width × A cuboid rock sample with a height of 150mm×35mm×35mm, (see figure 1 ); Use a grinding machine to grind the six sections of the cuboid test piece smoothly, requiring the non-parallelism of the two ends to be ≤0.01mm, and the diameter deviation to be ≤0.02mm. In order to maintain the stability of the mechanical properties of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com